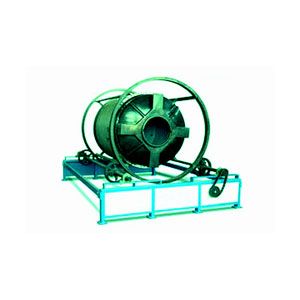

OPEN FLAME ROCK N ROLL ROTOMOLDING MACHINE

Get Price Quote

Owing to our state-of-art manufacturing unit and the usage of leading-edge techniques, we are able to present a comprehensive range of Flame Rock N Roll Machine.

Closed Oven Rotomolding machine

680,000 - 750,000 Per Piece

1 Piece (MOQ)

This NP Rotoplast closed oven RNR fully automatic machine is widely accepted by the market for it’s more productive, fuel efficient, energy-saving and cost-effectiveness. It has a closed oven thus making production more Economical, Easy mould mounting arrangement makes it flexible and improving the efficiency by 30% compared with other models. High utilization rate of oven makes machine more energy-saving and environment friendly; This is most suitable for simultaneous production of medium to large size products with similar moulding time. Features of closed oven rotomoulding machine : Optimum oven design leads to low gas consumption & Environment friendly More production/cycle due to multi moulds mounting arrangements Sufficient oven wall thickness to withstand working temperature 250 degree Celsius Bestselling machine for small & Medium scale business Best suitable for 50L to 20,000L water storage tanks Also suitable for small & Medium size of articles. Four windows given in door for 2nd,3rd charging to make multi-layer tanks easily For single mounting mould, material can be feed from screw Oven rocking & Door open close movement powered by Hydraulics Fully automatic Rolling & Rocking motion Auto ignition for burners for quick start PLC Automation (on request) Microprocessor based machine control with digital display (on request)

Best Deals from Rotomolding Machine

rotomolding machines

Get Price Quote

Rotomoulding machines are specially designed to hold large moulds as well as multiple moulds with various capacities. Provision for such large mould carrier plates and arms are provided for both side support for sturdy and comfortable operation instead of cantilever type station arms which is a special feature for the shuttle type machines.

rotomolding machines

Get Price Quote

The machine is Easy To Operate, Low Maintenance and Minimum Manpower required to operate. The Ultimate Machine products Large Size Hollow Tanks. Less Installation Cost and Easy Operating System with Control Panel. Machine Available upto 40000 Litres capacity tank Products.

Rotomolding Rotational Moulding Machine

300,000 Per Piece

Rotomolding Machine

Get Price Quote

Rotomolding Machine that we offer is controlled via modular, flexible and well-tested software system. It can be updated with new functions as per the requirements specified by the buyers. The electrical and electronic components used in our Rotomolding Machine are well tested and are procured from the trusted sources of the market. We are named among the renowned Manufacturers, Exporters and Suppliers of Rotomolding Machine. Details : Setting and visualization, in the user’s language of all process parameters (temperatures, rotation speed, reversal of rotation direction, carriage position, etc.); Possibility to view the oven temperature curves and the manual/automatic cycle; Visualization of alarms, with mandatory or proposed solutions, which requires the operator acknowledge before any action is taken; Visualization and setting of pre-arranged maintenance cycle; Several password levels to protect data and process from non-authorised changes; Audit-trail for trace ability of data changed by operators (optional); Direct control and management of arm inverters without opening electrical control panels; Possibility to replace inverters without the requirement of direct programming; Simple and clear visualization of cooking and cooling times; Management of the cooking recipes and codes for each arm; Automatic calculation of theoretical consumption of each arm; Automatic creation and saving of production reports on SD memory card or remote server; Possibility to mold up to 4 layers; Possibility to set 3 different temperature levels for each cooking period; Possibility to set 2 different speeds on the primary and secondary in the same cycle phase and of the clockwise/counter clockwise rotation time, with possible delayed intervention; “Zero” search for setting the mold position at the loading/unloading station; Provision for an eventual carriage addition; Provision for an eventual addition of an “automatic temperature management system”, with INTEL-ARM (optional), or other systems; Provision for an eventual addition of an “automatic hot air-flow” management system with INTEL-OVEN (optional); Provision for an “automatic mold recognition” with INTEL-RECIPE (optional); Display of current consumption; Display of motors, micro switch and doors opening and closing status

Plastic Rotomolding Machine

Get Price Quote

With our expertise in this domain, we put forth hi-tech Plastic Rotomolding Machine. The Plastic Rotomolding Machine, is available with different models and all models are manufactured in conformance to international standards. The Plastic Rotomolding Machine, we offer, is made from high-grade parts. Moreover, the Cooling tank is manufactured from stainless steel. The Barrel of Plastic Rotomolding Machine is heated by power saving heaters or gas system. Production Capacity : 30kg/hr to 300 kg/hr Specifications : The Recycling plant available in standard, vented and high L/D ratio versionPalletizer for producing palletsDrive from main A. C. motor to screw is via rubber belts and pulleys and a gear unitHeating control by temperature controllerFor accurate temperature control, we provide, Cooling systemHaving screw & barrel are fabricated from alloy steel & fully nitriding, hard chrome platingControl panel having digital temp controller & accessoryHeavy duty bearing housing with helical / worm gear box Technical Specifications ModelO/P (kgs/hr)Screw Dia (mm)L/D RatioMain Motor (kw)Rotory PelletizerHeating Load kwMotor Size(kw)AERP-6550-706526:112kw-15hp6"0.7512AERP-7570-1007526:115kw-20hp6"1.524AERP-90100-1209026:120kw-25hp6"1.530AERP-100120-16010026:123kw-30hp9"2.2532AERP-120150-25012026:140kw-50hp9"2.2540.

Single Station Rotomolding Machine

105,000 Per

1 Piece (MOQ)

rotomolding machines

Get Price Quote

rotomolding machines, rotomoulding moulds, bi axial rotomoulding machine

rotomolding machines

Get Price Quote

rotomolding machines, strip curtain

rotomolding machines

Get Price Quote

rotomolding machines, Transfer Moulding Machine, Septic Tank Mirror Mold

Shuttle Rotomolding Machines

Get Price Quote

Pick it for high volume generation (past 15000L/4000USG) Furnished with machine controls and vital interlocking Furnished with security gadgets and pointers and cautions Chip based machine control board with show Discretionary PLC for finish mechanization Condition benevolent burners appropriate for LPG/CNG/Duel Fuels Alternatively configuration warming chamber for vitality productive warmth exchange to the molds for quick and short process duration Extraordinary protection material for better workplace. Straight arm with four shape singular bearer for uniform thickness. Inbuilt shape situating and adjusting office Office to include Extra station for higher creation

rotomolding machines

Get Price Quote

rotomolding machines, Horizontal Water Tank Mould, Roto Mould Die

Rotomolding Rotational Moulding Machine

Get Price Quote

Rotomolding Rotational Moulding Machine

rotomolding machines

Get Price Quote

rotomolding machines

Plastic Rotomolding Machinery

Get Price Quote

Plastic Rotomolding Machinery, rotomoulding machinery

Rotomolding Rotational Moulding Machine

Get Price Quote

Rotomolding Rotational Moulding Machine, Cast Aluminum Molds, Roto Mould Die