Vibratory Knockout Machines

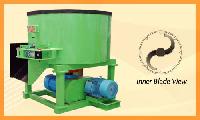

sand mix muller

The sand Mixer has two mullers with wide mulling face and proper weight to give efficient and maximum mulling action without crushing the sand. The mullers are in hinges and supported by springs which keep the mullers floating over the sand with Constant pressure. The gap between the mullers and pan plate can be easily varied to get the required strength.

...more

sand drier

Rotary Polygonal Screen

Screen housing sand suction hood with 2 connecting sockets form a closed casing around the screening basket. Bearing and drive the rotating screen are located outside of the housing. They are suitable for a sand moisture of about 2%. For lifting up the sand and creating a sand film, suitably shaped scoops are built into the screening basket. Design Features Screening: 'VME ' Rotary Screen assures even loosening and screening of foundry return sand. Solid parts and lumps are eliminated at the end of the screen. Disintegration of lumps: Large moulding sand lumps are largely disintegrated by the screening operation. The burnt-out outer layer of core sand lumps is rubbed off and passes the screen, the remaining lumps are discarded.

...more

Return Sand Disintegrator

Return Sand Disintegrator breaks up the lumps in the sand effectively and selectively. This is achieved by an impact rotor of suitable shape and circumferential speed in connection with movable impact grids.

...more

Reclamation Systems

Shake -out grids are machines using predominantly vertical vibration to separate castings and sand sand limps. They are predominantly used for large piece weights and low quantities. The material is charged by crane. After the process the de-sanded castings are removed y crane. Separator troughs are conveying installation using directional vibration to handle.

...more

Prepared Sand Aerator

Prepared Sand Aerators loosen and refine the sand very efficiently and carefully with a minimum of wear on the machine. The first rotor with arrow shaped vanes strips the sand, layer by layer, from the conveyor belt and flings it to the second rotor which takes the sand up, distributes, aerates and flings it onward.

...more

Pneumatic Sand Transporter

Pneumatic Thrust conveying is a discontinuous transport process from a closed vessel. It operates according to the cycle “fill - transport “. Compressed air thrusts the bulk material out of the pressure vessel through a transport pipe. In this conveying process, the cross section of the pipe immediately following the pressure vessel is completely filled. Depending on the setting and the properties of the product, plugs form, and the distance between these plugs increases. There is, However, no dispersed conveyance. The pneumatic conveyor is especially suitable for conveying dry, granular and free - following substances. The pneumatic conveyor is never fully emptied, so that each conveying process takes place against the full line. This reduces pipe wear and material abrasion considerably. They are compact in design, require little maintenance and make little noise.

...more

Moulding Machines

Ladle Preheater

Knockout Machine

Shake out machine is simple and robust machine designed for continuous duty to separate castings from sand, sand from flasks and cores from castings. INLINE KNOCKOUT MACHINE is of free floating twin eccentric shaft design. It is provided with a built - in Feeder trough. The Machine consists of the Main body, Feeder Trough, Eccentric shaft assembly, Base assembly with coil springs and drive unit. The main body is supported on a set of coil springs. The rotating eccentric shaft assembly is fitted at the top of the trough.The shaft run on high quality anti friction bearings. The bearings are well protected by housings to eliminate the entry of dust particles, to achieve longer life.

...more

Intensive Sand Mixer

Swing Frame Grinders

Swing Frame Grinders are of robust construction. The Grinding wheel is fitted on a shaft mounted on antifriction bearings housed in a sturdy housing. The housing with Grinding wheel assembly is fitted on one end of a tubular body and the drive motor on the other end. Motor drives the grinding wheel shaft through V belt transmission. Drive motor is included. Push button actuators are provided near the operating handle. Starter & switch fuse are excluded.

...more

Foundry Ladle

Design and manufacture an extensive range of foundry ladles that are suitable for all types of metal handling requirements. The ladles can be supplied as either standard configuration or custom designed to incorporate your special requirements.

...more

FLUID BED COOLER

Core Shooter

Features : High productivity, high - performance.

Core Sand Mixer

The success of this technology results primarily from the new mixing method. The sand in the mixing chamber is subject to strong acceleration and shear caused by the mixing blades and stator bolts, thus achieving optimal mixing intensity. Features New mixing principle Saving of binder and energy Good accessibility Easy cleaning High mixing intensity Best mixing quality High mixing capacity Saving of binder

...more

Continuous Shot Blasting Machine

compaction table

To ensure good moulding results it is essential that the sand is well compacted and it is for this reason that AXMANN has taken particular care in the design and realisation of the compaction tables. The most special feature is undoubtedly the possibility of regulating the frequency of the two electric vibrators, by means of a control inverter, positioned on the electrical panel itself. AXMANN has developed various models to meet the specific needs of the customer and they range from a minimum working capacity of 2000 Kg, to a maximum of 20,000 kg. Features * Two motors arranged to contra-rotate and produce a vertical linear motion. * Optional A.C. inverter control to provide infinitely variable vibration settings. * Design of Vibrating frame allows compaction of oversize moulds. *The rollers forming the roller track remain static and are free from vibration.

...more

cassette filter

Cassette filter consists of a dirty air inlet and distribution manifold, a dirty air compartment containing the filter cassette, a clean air compartment, a cleaning air nozzle, a drive unit, a cleaning air fan located on the top, a dust collection hopper with dust disposal equipment, support structure and platform. Operation of Cassette Filter : The captured dirty gas is led to the dirty air compartment from top by way of the dirty air inlet and distribution manifold. The gas travels downwards through the filter cassettes lined up in rows and then into the clean air compartment. During dust collection, the filter cassettes undergo automatic cleaning by a reverse air flow system. During cleaning the cleaning air nozzle always covers three column in the middle receives the cleaning air without any dust drawn from the two neighbouring cassettes.

...more

Bucket Elevator

Sand preparation plants consist in large part of storage and conveyor systems. The use of functional, tested equipment,adapted to the special requirements of foundries, is therefore of special importance. Depending on the layout, structural arrangement and construction costs, preference is given to row or tower arrangements, whereby tower sand preparation plants have the advantage of requiring less floor space. For vertical conveyance of foundry sands, VME’s build belt bucket elevators with standardized bucket widths of 315 to 1600 mm and conveying capacities up to 500 Thr.

...more

Blast Cleaning Machine

pinner hanger roto blast cleaning machine is specifically suitable for surface treatment and desanding of castings, descaling of forgings, and deburing of aluminium parts, especially for those work pieces which are not suitable for tumbling because of their shape or size. Several models are available with load capacities of up to 15000 kg per hook as standard. Special types also can be designed and supplied to suit customer’s requirements.

...moreBe first to Rate

Rate This