Brazed Plate Heat Exchangers

Get Price Quote

Air conditioning We offers a wide range of highly efficient, compact, and versatile heat exchanger solutions for air conditioning systems. Chillers The purpose of a chiller is to remove heat from a liquid via a vapor-compression or absorption refrigeration cycle. The evaporator and the condenser are essential parts in a vapor-compression cycle. RefrigerationWe offers a full range of BPHEs engineered to deliver the highest COP and the lowest life-cycle cost. The segment includes the supermarket and transport application areas.Industry :- which includes industrial chillers, cooling for oil, laser and electronic systems as well as cooling and drying of compressed air systems & also suitable for fuel oil. Typical Applications HVAC Heating / Cooling Refrigerant Applications Industrial Heating / Cooling Oil Cooling

Brazed Plate Heat Exchanger

Get Price Quote

1 Piece (MOQ)

Best Deals from Brazed Plate Heat Exchanger

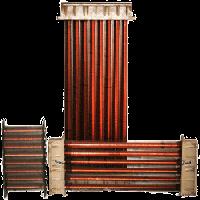

Brazed Plate Heat Exchangers

15,000 - 15,000 Per Piece

1 Nos (MOQ)

The product range of our brazed series offers the widest variety and flexibility in terms of size, brazing material, different connections, flow arrangements and accessories. Benefits of Brazed Plate Heat Exchangers: Tailor-made economical design for the most varied applications Long lifetime Highest efficiency Highest quality

Copper Brazed Plate Heat Exchangers

100 - 9,000 Per Piece

1 Piece(s) (MOQ)

Brazed Plate Heat Exchangers

Get Price Quote

Brazed plate heat exchangers are quickly winning ground, thanks to their many advantages over other technologies. SWEP BPHEs provide efficient, stable, and reliable performance in a robust and easily handled unit. Customized to achieve the required characteristics of each specific application, they ensure the highest performance with the lowest life-cycle costs. You have a lot to gain from choosing our BPHEs for your next heating or cooling project. SWEP heat exchangers are available in a wide range of sized with Copper, SS316 and Nickel Brazed SS316 plates.

Kaori Brazed Plate Heat Exchanger

Get Price Quote

Kaori brazed plate heat exchangers kaori bphe (brazed plate heat exchanger) can be utilized for a wide range of non-fouling liquid media and gases. applications include: # hvac heating and cooling # hot-water producing plant (central heating) # district heating systems # condensers and evaporators in chillers and heat pumps # industrial and chemical processes # hydraulic oil cooling # heat recovery from hot waste streams # boiler blowdowm # radiant floor heating # snow melt operations advantages: # compact unit, low weight # less space required # low cost for same result # no gaskets, no leaks # high heat transmission rate # high operation temperature and high working pressure # sus316 (aisi 316) stainless steel for effective corrosion resistance # easy installation and replacement, low maintenance requirements materials: # plate material: sus316 (aisi 316) # solder material: 99.9% copper # test pressure: 40 bar # working pressure: max. 30 bar # working temp.: -195oc ~ 225oc

Bazed plate heat exchanger

Get Price Quote

Brazed Plate Heat Exchangers offer the highest level of thermal efficiency and durability in a compact, low cost unit. The corrugated plate design provides very high heat transfer coefficients resulting in a more compact design. The units stainless steel plates are vacuum brazed together to form a durable, integral piece that can withstand high pressure and temperature. Brazed Plate Heat Exchangers offer the highest level of leak protection, safety, thermal efficiency, and durability in a compact low cost unit. True double wall construction including port regions Double wall plate design with unique air vent leak paths Complete peripheral braze for additional strength Four dedicated leak ports for quick and easy leak detection Excellent performance for domestic and potable water applications

Brazed Plate Heat Exchanger

5,500 Per Piece

Brazed Plate Heat Exchangers

Get Price Quote

We are offering brazed plate heat exchangers, designed for maximum performance, the gireesh heat exchanger's compact, rugged assembly is composed of stainless steel plate packs sealed together by means of brazing metal along the border of the units. This eliminates the need for traditional gaskets or external pressure retaining parts. the plate packs are embossed with special corrugation patterns to promote high turbulence flow, which dramatically increases the heat transfer rates of the units thus making them a highly economical and effective solution for many processes and heating applications. Applications • central heating • oil coolers • hedonic heating • solar and geothermic heating • industrial process heat recovery • condensers and evaporators in refrigeration systems • close approach fluid-to-fluid heat transfer • excellent for use in wood boiler industry.

Brazed Plate Heat Exchangers

Get Price Quote

We Manufacturer and Exporter of all types of Brazed Plate Heat Exchanger (BPHE) in India, Established in the year of 1989. We are a genuine, reliable and durable Cooling Solution for all types of industries in India as well as overseas. Brazed Plate Heat Exchanger Applications Heat-pump Boilers Evaporators Hydraulic oil cooling District heating Thermal power stations Refrigeration Oil coolers Air conditioning Outdoor wood boilers, stoves, furnaces Domestic water heating Solar energy and chiller applications Brazed Plate Heat Exchanger Advantages We provide high quality Compact design Three way design for heat pumps Higher Heat Transfer High corrosion resistance Low investment costs for BPHE Simplify maintenance and repair with BPHE Versions for standard and high pressure operation

Brazed Plate Heat Exchangers

Get Price Quote

Brazed plate Heat Exchanger is constructed of a series of Pressed corrugated plates in stainless steel. These plates are stacked one over other with copper foil in between for Joining and kept in oven for brazing together. The plates are stacked in such a way that flow passage one side primary fluid and another channel secondary fluid passage. Features: Small Footprint Lower Hold-up Volume No Gaskets to Replace High and Low Temperaturesv BPHE plates and channel types Certain BPHEs are available with different types of channel plates where the herringbone pattern varies. The benefit of different herringbone patterns is that the hydraulic and thermal characteristics of the BPHE can be modified. For example, two BPHEs can have the same pressure drop on both sides despite different flow rates. The fluids can pass through the heat exchanger in different ways. For parallel flow BPHEs, there are two different flow configurations: co-current or counter-current There are several different versions of the channel plate packages. Examples include: Dual-circuit BPHEDual-circuit BPHE Two-pass BPHE, which corresponds to two units connected in series. Dual-over-two-pass BPHE Material combinations There are different BPHE product categories depending on material combinations and design pressures. The standard plate materials are AISI 316 stainless steel, S, vacuum-brazed with a pure copper filler, C, or a nickel-based filler, N. For demanding applications, the plates can be made of SMO 254, a stainless steel with a higher content of molybdenum.

Brazed Plate Heat Exchangers

Get Price Quote

Characteristics Capacity: 1 to 200 kW Features Very economical to buy install and operate very compact and light entirely welded Their design guarantees an exceptional mechanical resistance and perfect tightness

Brazed Plate Heat Exchangers

Get Price Quote

A plate type heat exchanger is a type of heat exchanger that uses metal plates to transfer heat between two fluids. This has a major advantage over a conventional heat exchanger in that the fluids are exposed to a much larger surface area because the fluids spread out over the plates. This facilitates the transfer of heat, and greatly increases the speed of the temperature change. It is not as common to see plate heat exchangers because they need well-sealed gaskets to prevent the fluids from escaping, although modern manufacturing processes have made them feasible. The concept behind a heat exchanger is the use of pipes or other containment vessels to heat or cool one fluid by transferring heat between it and another fluid. In most cases, the exchanger consists of a coiled pipe containing one fluid that passes through a chamber containing another fluid. The walls of the pipe are usually made of metal, or another substance with a high thermal conductivity, to facilitate the interchange, whereas the outer casing of the larger chamber is made of a plastic or coated with thermal insulation, to discourage heat from escaping from the exchanger. The plate heat exchanger (PHE) was invented by Dr Richard Seligman in 1923 and revolutionized methods of indirect heating and cooling of fluids. Brazed Plate Heat Exchangers Applications Domestic water heating Hydraulic oil cooling Hydronic heating and cooling Snow melt systems Outdoor wood boilers, stoves, furnaces Radiant floor heating Beer and wort chilling and other water to water and liquid to liquid heat transfer applications Plate type heat exchanger one is composed of multiple, thin, slightly-separated plates that have very large surface areas and fluid flow passages for heat transfer. This stacked-plate arrangement can be more effective, in a given space, than the shell and tube heat exchanger. Advances in gasket and brazing technology have made the plate-type heat exchanger increasingly practical. In HVAC applications, large heat exchangers of this type are called plate-and-frame; when used in open loops, these heat exchangers are normally of the gasket type to allow periodic disassembly, cleaning, and inspection. There are many types of permanently-bonded plate heat exchangers, such as dip-brazed and vacuum-brazed plate varieties, and they are often specified for closed-loop applications such as refrigeration. Plate heat exchangers also differ in the types of plates that are used, and in the configurations of those plates. Some plates may be stamped with "chevron" or other patterns, where others may have machined fins and/or grooves. Liquid foods such as milk, fruit juices, beers, wines, and liquid eggs are pasteurized using plate-type heat exchangers. Wine and fruit juices are normally deaerated prior to pasteurization in order to remove oxygen and minimize oxidative deterioration of the products. Plate-type heat exchangers consist of a large number of thin, vertical steel plates that are clamped together in a frame. We manufacture plate heat exchanger that are used in dairy, pharma and biotechnology, beverages, brewery, chemical and power sectors. PHE plates are available in MOC AISI 304, AISI 316, AISI 316L, Titanium, Hast alloy, Monel in range thickness from 0.5mm to 0.9mm. It is suitable for handling fluid from 100 LPH to 3.5 Million LPH.. Safety:Our plates are provided with double gaskets at the inlet and outlet which prevent mixing of the two media. If designed as safety heat exchanger, double plates are provided with a special sealing system.Plate material:§ standard: stainless steel 1.4301/AISI 304, 1.4401/AISI 316 § optionally: 1.4539, 254 SMO, titanium Gasket material:§ NBR (nitrile-rubber) § EPDM (ethylene-propylene-rubber) § Viton (fluorine-rubber) § Further materials on request Special series:§ Safety heat exchangers (FPSS) § Stainless steel design for food and FDA applications § Compact double PHE-units including cocks and valves § Design with welded cassettes (FPG) We manufacture and supply highest quality range of plate heat exchanger using the most advanced technology for a wide series of heat transfer applications used in various industries such as chemical industry, offshore, oil and gas, petrochemicals power plants, pulp and paper, steel, zinc and aluminium, sugar, vegetable oil, breweries / distilleries, dairy / beverages and others. The difference lies at plate design, sealing technology, capacity range, product range etc. We always continue to improve our products to give total customer satisfaction. Brazed Plate Heat Exchanger Features High heat transfer coefficients Optimized heat recovery Compact constructions No mixing of product Flexibility to change plate arrangement and to add / remove plate Easy maintenance and suitable for CIP, plate pack easily accessible The brazed plates form two separate channel systems. The two media assume a true countercurrent flow, completely isolated from each other. This channel configuration is designed to produce high turbulence, promoting maximum heat transfer.

Brazed Plate Heat Exchanger

15,000 Per Piece

Brazed Plate Heat Exchangers

Get Price Quote

We supply brazed plate heaat exchangers for lube oil and hydraulic oil cooling and chilling pants. Also, for sevral industrial uses.

Danfoss Brazed Plate Heat Exchanger

Get Price Quote

Danfoss Brazed Plate Heat Exchanger, Danfoss Pressure Switches