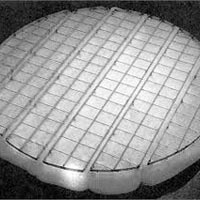

Down Style Demister Pad

Get Price Quote

We are amidst the credible Manufacturers, Suppliers and Exporters of Down Style Demister Pad. Designed keeping in mind the set industrial standards for quality, this Down Style Demister Pad is designed using the cutting-edge technology. We offer the Down Style Demister Pad at the market leading rate to the customers.

Demister Pad

Get Price Quote

Best Deals from Demister Pads

Knitted Mesh Demister Pads

Get Price Quote

Available as Stainless steel demister pad Titanium demister pad Alloy demister pad Galvanized demister pad Copper demister pad Features Simple structure Small size Light weight Reduce air pollution Long life Easy installation Excellent separation efficiency Requires no maintenance Anti corrosion Can sustain under high or low or temperature Applications Steam drums Absorbers Scrubbers Evaporators Refining vacuum towers Refining lube towers Separators vessels Knock out drums Process vessels handling liquid and vapor

Demister Pad

3,000 - 5,000 Per piece

100 piece (MOQ)

Demister Pads

Get Price Quote

Our company is an eminent Demister Pads Manufacturer, Importer, Exporter, and Supplier in Mumbai. The Demister Pads which we offer are made from high-grade quality raw materials procured from the reputed vendors only. These Demister Pads which we bring forth have excellent finish and accurate dimensional quality, making them extremely suitable to be used in different industries. The Demister Pads provided by us are available in different specifications. Clients can avail the Demister Pads from us at affordable price in market. Why Our Demister Pads? High removal efficiency No maintenance or service required Negligible pressure drop Easily installed in existing vessels Corrosion resistant properties About Demister Pads : Demister pad is also called as Mist Eliminator Carryover of liquid particulate along with gas or vapor is generally termed as �mist� or "Entrainment", which is commonly encountered in Gas-Liquid separations Mechanism Of Mist Eliminator / Demister Pad : Mist is a generic term for entrainment, where the size of entrained liquid droplets is less than 10um. When mist laden vapors passes through the knitted wire mesh the vapors moves freely through the mesh but the liquid droplets, when droplet come in contact with knitted mesh it will get collected and they collapse in form of large droplets due to gravity force . Advantages : It minimizes products losses in kettles, re boilers, vacuum pans, crystallizers and evaporators Use to control air pollution, to eliminate toxic mist from gases, e.g. Sulphuric acid plants It reduce solvent losses in absorbers, scrubbers, distillation equipment e.g. Amine treating systems In Refinery towers to prevent carbon and metal entrainment to downstream catalytic cracker and reformer units Note : QWP CS TYPE : Custom Made On many cases Teflon; Polypropylene and Polyester mono & multifilament demisters are made upon special request from customers. Mesh Pad Density; Surface area; and free volume will be provided upon request. These type of mesh are called QWPCS Type : CS stands for Custom Made Mist Eliminators are manufactured in all grades of Stainless Steel and other special alloy like Monel; Inconel; Alloy 20; Hastealloy & Titanium Typical Mist Eliminator Fastener Details : Tie Wire J Bolts I Bolts Cleats and Langles Standard Grid Specifications : Grid Specifications Width mm Thickness mm Material Flat Bar Specifications 15 to 50 mm 2.0mm to 6mm Same as Mist Eliminator Type Rod Specification Round 4.0mm to 10mm Same as Mist Eliminator Type

Demister Pad

Get Price Quote

1 Piece (MOQ)

Applications Knock-out Drums Evaporator Systems And Absorbers Scrubbing Systems And Absorbers Glycol Dehydration Gas Processing Inert Gas Scrubbers Sulphuric Acid Drying Towers Sulphur Condensers Steam Drums Intel Separators Turbo-expander Suction Drums Dew-point Separators Compressor Suction Drums

Demister Pads

5,000 - 90,000 Per Piece

1 Piece (MOQ)

Product DescriptionBacked with rich expertise and knowledge in this field, we are counted amongst the foremost manufacturers and exporters of finest quality Demister Pads. We design and manufacture these pads as per the industrial quality and standards using different types of quality materials. Demister Pads, we are offering in the market, find wide application in diverse industries of chemical, petrochemical, petroleum and refining industries.Further DetailsDemister Pad is also known as mist eliminator, diesel injector filter, knitted wire mesh, mister screen, socks e.t.c. We manufacture demister pads as per customer specifications.Application :GWWSL demister pads have used in gas-liquid separation e.g. moisture separators for compressed air and column packing pads. Demister pads are also used in the separation of water droplets from Steam. These pads have a wide range of applications in the chemical industry, petroleum industry, pharmaceutical industry, and separation equipment manufacturing.Demister pads are effective in separating liquid phase from the vapor phase. Typically demisters are mesh-type coalescers but can be constructed of a vane pack as well. The function of Demister Pad is to coalesce fine droplets so that the combined drop is heavy and pulled down due to gravity. Usage of Demisters can help in the reduction of the size of Separator Vessels. The gas/vapor exiting the Separator Vessel is devoid of liquid droplets.Working Principle :Demisters are employed for the separation of the Liquid Phase from the Gaseous Phase. Gas or Vapour carries liquids in small droplet form. When the Gas / Vapour passes through the demister pad, the fine liquid droplets collide with the filaments of the demister pad. Small droplets adhere to the filament. A sequence of droplets keep joining onto the filament and eventually combine to form bigger drops that are heavy enough to be pulled down due to gravity. The gas being lighter is usually routed to exit from the top of the Separator Vessel and the Liquid from the bottom. Thus, Demister Pads are very effective in Gas-Liquid Separation.Structure:Single Piece or Multiple Pieces for installation through Man Hole. With Support Grid or Without Support Grid, depending on customer requirement.

Demister Pads

Get Price Quote

Demister Pad

Get Price Quote

10 Piece (MOQ)

Features : High removal efficiency Negligible pressure drop, less than 25mm of water gauge No maintenance or service required No corrosion or temperature limitations Easily installed in existing vessels No limitation on size or shape. Mist Eliminators are used to remove liquid droplets from a gas stream to : Control stack emissions to the atmosphere. Eliminate or reduce damage of equipment caused by corrosive or fouling liquid droplets. Recover valuable liquids. Many processes for the production of sulfuric acid, chlorine, inorganic fertilizers and refined oil products rely heavily on well designed mist elimination equipment.

Monel Demister Pad

Get Price Quote

Feel free to place the small or bulk orders of Monel Demister Pads with us. We are the reputed Maharashtra-based Manufacturer, Supplier and Exporter of Monel Demister Pads across the globe. Made in tune with the set industrial norms, our Monel Demister Pads are appreciated for their accurate construction, robustness, and effective use. Owing to our state-of-the-art production facility, we can make available these Monel Demister Pads in plenty of specifications.

Demister Pads

Get Price Quote

We are engaged in the manufacture and supply of superior quality Demister Pads in the industry. The Stainless Steel Demister Pads ( Mist Eliminator ) offered by us are used for carry over particulate matter by gas or vapor, generally termed as "Entrainment" is commonly encountered in Gas-Liquid separations. They are cost- efficient means of separating Entrained liquid droplets from gas and vapor stream. Demister Pads are installed at some distance above the surface of liquid that allows free disengagement of mist droplets and the coarsest particles. Construction : Demister Pads are essentially porous blankets of carefully knitted wire or synthetic fibers designed and constructed to efficiently abate mist particles. After knitting each layer is corrugated and converted into Pads of different shapes and sizes. The Demister is generally supported by Grids as they are not entirely rigid. Efficiency : When properly designed Demister Pads can give Efficiency up to 99.9% with minimal pressure drop. Normally Demister Pads can remove droplets down to 5microns and lower with a free volume of up to 99% and a surface area of up to 1940 m2/m3. Due to high value of free volume the pressure drop across the demister pad is sufficiently low, negligible for most applications. Function : Demister Pads are installed at some distance above the surface of liquid allows free disengagement of mist droplets and the coarsest particles. The vapour/gas-liquid mixture run at a predetermined velocity through the Demister Pad, the vapour/gas finds an open path through the mesh easily, but due to greater inertia the droplets and mist impinge on the mesh and gradually increase to a bigger size and fall down due to gravity allowing the vapour/gas to pass freely without any Entrainment from the top of the Demister Pad. Column Packing : It is used for efficient packing of Distillation columns, which operate at Vacuum or Atmospheric pressure. Column Packing are fabricated by knitting fine wires into a mesh then further crimping the mesh before rolling them for a desired column diameter. Multifilament mesh gives best results due to their capillary action and promotes excellent mixing in vapour stage. Advantages of Demister Pads Solves Emission control Problems. Eliminates or reduces damage caused to the equipment due to corrosive liquid droplets. Recovery of valuable liquids. Improves purity of gas/vapour for further processes. Improves overall process economics. Increases process efficiency. Materials of Construction : Demister Pads are made of a variety of Materials as per application demands. A few materials of construction would be synthetic fibers, copper, aluminium, Stainless Steel 304, Stainless Steel 316, Monel, Nickel, Brass, Phosphor Bronze, Carbon Steel, etc,. for different applications like corrosive services, nitric acids, water solutions, Freon, alcohols, fatty acids, corrosive chemicals, food products, hydrocarbons, caustic soda, dilute acids etc.

PP Demister Pad

1,000 - 100,000 Per pc

1 Piece (MOQ)

Demister Pads

Get Price Quote

Specially designed & fabricated from knitted wire of various metallic materials with or without grid support to suit the specific process configuration. It is used for separation of liquid matter in gas or vapor. Our Demister Pads are tailor made units, designed to achieve the optimum results with minimum drop in pressure. It is also called Mist Eliminator.

Demister Pad and Coalescers

Get Price Quote

100 Piece (MOQ)

Demister Pad

Get Price Quote

We are one of the renowned and reliable manufacturers, supplier, stockist and exporter of Demister Pad in Mumbai, India. The Demister Pad that we offer carries over liquid particulate matters by gas or vapour. These Demister Pads are generally termed as "Entrainment", which is commonly encountered in Gas-Liquid separations. Our range of Demister Pads are the widely acclaimed entrainment eliminator and is specially designed and fabricated from knitted wire of metallic or synthetic materials. The demister pad we manufacturers meets the specific process configuration in existing or new equipment of our clients. Moreover, these demister pads achieve 99.9% and more separation efficiency with minimum pressure drop. Product Range of Demister Pad Stainless Steel Demister Pad : We are one of the renowned and reliable manufacturers, supplier, stockist and exporter of Stainless Steel Demister Pad in Mumbai, India. Carbon Steel Demister Pad : We are one of the renowned and reliable manufacturers, supplier, stockist and exporter of Carbon Steel Demister Pad in Mumbai, India.

Wire Mesh Demister Pad

Get Price Quote

MIST Eliminator/ Demister Pad/ Coloumn Packings Knitted Wire Mesh Or Air Filter Mesh These are latest and excellent means of Separating mist from vapour gas used mainly in fertilizer/ chemical and petro chemical industries etc

Demister Pads

Get Price Quote

Carryover of liquid particulate matter by gas or vapor is generally termed as "entrainment", which is commonly encountered in Gas-Liquid separations. The Demister Pads, offered by us, are an entrainment eliminator, mass-produced exclusively by us. Our Demister Pads are specifically designed and fabricated from knitted wire of metallic or synthetic materials, to suit specific process configuration in existing or new equipment. When properly installed, the Demister Pads achieve 99.9% + separation efficiency with minimum pressure drop. Applications To minimize product loss in kettles, re-boilers, vacuum pans, crystallizers and evaporators e.g. Sugar Crystallization To eliminate entrainment in knock-out Drum and Receivers To eliminate entrainment that might damage compressors To supplement equipment like Carbon absorbers and Electrostatic precipitators In air pollution control, to eliminate toxic mist from off gases, e.g. Sulphuric acid plants To reduce solvent losses in absorbers, scrubbers, distillation equipment e.g. Amine Treating Systems In Automobile Industry, as protective insert in upholstery, vibration and shock damping, noise and sound reduction In flame and spark extinction, as cross country gas/inflammable product pipelines, furnaces, ovens, vent tanks containing flammable liquids and flare gas systems Sealing - Gaskets made of knitted wire mesh having different degree of re-silences - e.g. in cable industry, radiation, shielding, automobile and computer industry. In Refinery towers to prevent Carbon and Metal Entrainment to Downstream Catalytic Cracker and Reformer units In Liquid-Liquid systems such as Coalesces

Demister Pad

Get Price Quote

demister pads offered by us are applicable for effectual entrainment of liquids or mist removal in any liquid or gas. We fabricate demister pad from firmly knitted mesh grids of stainless steel. Clients can avail these demister pads in different sizes and specifications and they can be installed in any existing or new process vessel. In addition, our demister pads can also be customized as per the details provided by the clients. working of demister pad when vapor carrying entrained liquid droplets or mist passes through the advance mist eliminator, the vapor passes freely through the layered mesh structure of the advance mist eliminator. The liquid droplets on the other hand, having greater inertia, contact the large wire surface exposed and briefly held there. As more droplets collect, they coalesce and grow in size and become large enough to drain back into the system. The overhead product is pure vapor, containing practically no liquid. features sturdy constructiondurableeasy to usesmooth operationcost effective applications petroleum industrychemicals industrymetallurgy industrypharmaceuticals industryautomobile industry materials of construction gimonelpolyproplenehdpenylonstainless steel size 25 mm - 2000 mm

Demister Pads

5,500 Per Piece

Demister Pads

10,000 - 25,000 Per Piece

Demister Pads

2,000 Per Piece

Wire Gauze Demister

Get Price Quote

We are the main supplier of this product.

Demister Pad

Get Price Quote

Supplying from our facility in Vadodara(India), our organizations is a well-reckoned provider in the market. Packaging of products is what we equally focus on. Our industry experts follow all the quality parameters while wrapping the products, we only use exceptional packaging material. MOCs.: S.S, ALLOYS, PTFE, P.P ETC.These are Metal / PP wire knitted pads with maximum openings and contact surface. Useful to trap liquid droplets escaping along with vapour. Thus it prevents high boiler products droplets carry-over into low boiler top condenser and acidic or corrosive mist droplets escape from the vent of the gas scrubber.

Demister Pads

Get Price Quote

2 Piece (MOQ)

Demister Pad

3,000 - 15,000 Per Piece

Demister Pads

4,000 - 5,000 Per Piece

Demister Pads

Get Price Quote

We bring forth high quality Demister Pads with perfect make. These Demister Pads separate mist & entrained liquid from any gas flow. Our Demister Pads are manufactured with the use of the finest quality metals and other materials to make them longer lasting and strong. These Demister Pads are corrosion resistant and are precision engineered to have perfect dimensions. Grids of S.S. firmly secure these Demister Pads. Made From Knitted Mesh Of Stainless SteelMonelG.ITeflonPolyrolene

Demister Pads

Get Price Quote

Demister Pads are porous blankets of wire or plastic knitted mesh, designed and constructed for efficient and economical removal of entrained liquid droplets from vapour streams. The pads can be fabricated in any desired size and shape.

Wire Mesh Demister Pad

2,000 Per Piece

1 Piece (MOQ)

Wire Mesh Demister Pads

Get Price Quote

Demister pads, also called mist eliminators, are distinctly powerful devices designed to take away liquid droplets or mist from a gas movement. They may be typically utilized in numerous manner industries to ensure that product high-quality is maintained and the system is covered from harm because of entrained liquid droplets. The demister pads are a product of Knitted wire mesh, that is fashioned right into a dense, 3-dimensional shape with a high floor place. The mesh is designed to seize and hold liquid droplets because the gasoline move passes through it, allowing smooth fuel to exit. The demister pads may be fabricated into a spread of substances to healthy the precise needs of every software of our clients. they're to be had in a number of well-known sizes and can be custom-designed to fit any size or form of vessel. The pads may be installed in horizontal or vertical configurations and are designed to be effortlessly eliminated for cleaning or substitute. they're particularly durable and immune to corrosion, making them ideal to be used in harsh environments. Demister pads are utilized in a wide variety of programs. they're vital for making sure the safe and green operation of devices and processes. Features of Wire Mesh Demister/mist eliminators High Efficiency Low-pressure drop Corrosion Resistance Easy installation and maintenance Customizable Design Temperature Resistance Compliance with Standards Cost-Effective Solution