Automatic Batching System

Get Price Quote

1 Piece (MOQ)

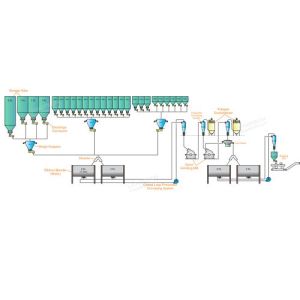

A Sample Process flow of the system Silo of 1 Ton (1 unit): This Silo would be mounted on the load cell and would indicate the weight of the material filled in it. A complete batch including different ingredients would be made here manually by checking the weight of each item while filling. Vibratory Feeder (1 unit): This Feeder would be placed each at the bottom of the Silo to feed the material in the Z Type Elevator. Z-Type Elevator: This would carry the material from the discharge of the Vibratory feeder and will convey it to the Mixer via the Diverter. Y – Diverter: This would be mounted at the outlet of Z Elevator. It would be pneumatically operated by a manual solenoid valve and would alternately feed the 2 Mixers Mixer 750 Kg (Twin): This would thoroughly mix the Ingredients received from the weigh hopper. It has a 10HP main motor Mixer. The discharge valve below it is of Flap type operated by pneumatic cylinders, which while in closed condition doesn’t allow any material to get accumulated over it. Collection Hopper (1 Ton): This would be mounted below the 2 mixers and would take the discharge from both of the mixers Screw Conveyor (1 unit): This would convey the material from the outlet of the Collection Hopper and would feed at the inlet of the Bagging Station. Bagging Station (1 Unit): The bags of 50 Kg each would be filled here it consists of two outlets for each where the material would come alternately. While one bag is getting filled in the 1st outlet, the 2nd would be stopped and will be replaced with a new bag manually. The Weight scale is placed below the two outlets which would automatically weigh 50 Kg and then switch the discharge to the other outlet.

Automotive Sheet Metal Components

5 - 50 Per Piece

5000 Piece (MOQ)

Best Deals from Automation System

Water Softening Plant

32,000 - 32,500 Per piece

1 Bag (MOQ)

Sheet Metal Automobile Components

5 Per Piece

10000 Piece (MOQ)

PLC Hardware

20,000 - 24,700 Per piece

1 piece (MOQ)

OAK-D-POE OpenCV AI Machine Vision Kit

Get Price Quote

1 Piece (MOQ)

Motion Control System

75,000 - 150,000 Per Unit

Automatic Batching System

Get Price Quote

1 Piece (MOQ)

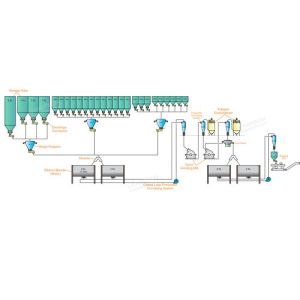

A Sample Process flow of the system Silo of 1 Ton (1 unit): This Silo would be mounted on the load cell and would indicate the weight of the material filled in it. A complete batch including different ingredients would be made here manually by checking the weight of each item while filling. Vibratory Feeder (1 unit): This Feeder would be placed each at the bottom of the Silo to feed the material in the Z Type Elevator. Z-Type Elevator: This would carry the material from the discharge of the Vibratory feeder and will convey it to the Mixer via the Diverter. Y – Diverter: This would be mounted at the outlet of Z Elevator. It would be pneumatically operated by a manual solenoid valve and would alternately feed the 2 Mixers Mixer 750 Kg (Twin): This would thoroughly mix the Ingredients received from the weigh hopper. It has a 10HP main motor Mixer. The discharge valve below it is of Flap type operated by pneumatic cylinders, which while in closed condition doesn’t allow any material to get accumulated over it. Collection Hopper (1 Ton): This would be mounted below the 2 mixers and would take the discharge from both of the mixers Screw Conveyor (1 unit): This would convey the material from the outlet of the Collection Hopper and would feed at the inlet of the Bagging Station. Bagging Station (1 Unit): The bags of 50 Kg each would be filled here it consists of two outlets for each where the material would come alternately. While one bag is getting filled in the 1st outlet, the 2nd would be stopped and will be replaced with a new bag manually. The Weight scale is placed below the two outlets which would automatically weigh 50 Kg and then switch the discharge to the other outlet.

Wecon Cloud SCADA Software

Get Price Quote

1 Piece (MOQ)

Packaged Drinking Water Plant

Get Price Quote

Some standard features these are known for include providing superior purification support, corrosion & abrasion resistant finish and high tensile strength. These Packaged Drinking Water Plant provide vital assistance in the elimination of impurities including dust, mud as well as microbiological contaminants that pollute the water and make these unfit for usage. These plants also provide for cost effective solutions for purification of water and find extensive usage in food processing, mineral water processing, and other industry sectors.

Automotive Components

Get Price Quote

Plain & flanged bushes and parts, self aligned bushes, & different profile components as per drawing samples.

Water Softening Plant

Get Price Quote

A Water Softening Plant is used for the purpose of softening the hard water by removing calcium, magnesium and other metal cations. Water Softening is a simple process of ion-exchange and in this process calcium & magnesium ions are exchanged by sodium ions. Our Water Softening Plant is widely acknowledged by the clients owing to its excellent performance, sturdy construction, low maintenance and easy operation. Water Softening Plant that we offer is extensively demanded in hospitals, schools, commercial or residential buildings, etc., in order to minimize the probability of scaling installation. Special Note : To control level of TSS–TOTAL SUSPENDED SOLIDS (undiluted impurities & sand particles entering in Tower Basin) in cooling tower water installation of online sand filter is must. It will enhance efficiency of softener resin by protecting it from getting covered by sand.

Domestic Society Automation System

Get Price Quote

We offer a wide range of Domestic Society Automation System to our clients at reasonable rates in the market. Being the main Manufacturer, Exporter and Supplier of Domestic Society Automation System from Maharashtra, India, our range of Domestic Society Automation Systems have a number of specifications like climate control options, control of doors and window shutters, and security and surveillance systems. The Domestic Society Automation Systems are ideally used in applications of automation techniques for comfort and security of its residents. Features: Intruders Domestic Help Untrained Security Staff Maintenance Staff Specification: Climate control Control of doors and window shutters Security and surveillance systems etc.

Precision Automotive Component

100 - 150 Per

1000 Bag (MOQ)

wheel box shaft used in wiper motors. shackle , key bush pin

Auto Batching System

Get Price Quote

Weighing & batching solution for complete process automation Independent & ratio metric flow rate control, heating & cooling profile control, agitation control Automation through reputed make PLC & HMI for complete process over viewing and control. SCADA for remote control & report generation with time trend.

European Commercial Vehicle Components

1,500 Per Piece

Touch Screen PLC Operating System

Get Price Quote

The touch panel PLC operating system allows the user to control all the system parameters with the touch of a finger. The blower, air heater and feed liquid pump are operated from this panel. The system parameters such as inlet hot air temperature, outlet exhaust air temperature, feed and blower frequency are set by touching the corresponding displayed value and entering the new value in the set screen that appears.

Industrial Automation System

Get Price Quote

1 Cubic Meter (MOQ)

Full Vision Print Inspection System

Get Price Quote

SPECTRO vision systems are able to control the 100% of the decorated surface and to detect the typical defects produced during the printing process. SPECTRO systems have been specifically studied to control the 100% of the production directly on the production line. SPECTRO is specific for aluminium or plastic tubes, caps, cans and each cylindrical objects. Normally it is collocated on the printing machine, inside a unit where it is possible for the tube to be in rotation and where a rejection system for the defected tubes could be carried out.

Machine Vision Equipment

5,000,000 - 10,000,000 Per Piece

Machine vision system for defect free textile