Cyclone Separator

100,000 - 5,000,000 Per Piece

Cyclone Separator

Get Price Quote

Best Deals from Cyclone Separators

Cyclone Separators

Get Price Quote

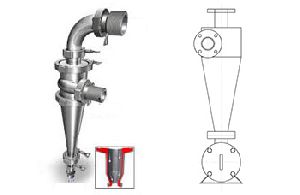

We offer wide range of Cyclone Separators This is a device to separate solids (in powder or granular form) from air/gases. When the material is moving as in pneumatic conveying, the solids are separated. In this device, air is made to flow at cyclonic speed and made to rotate in a cylindrical vessel of suitable design. When the solid material attains high speed, it picks up centrifugal force and choose to hold tightly to outer surface while air retains high speed it gets due to its velocity factor. Suddenly in the center, air outlet is provided for air to go out while due to centrifugal force the solid material is not able to change direction but goes downwards and gets separated. This device is capable of offering separation efficiency up to 90 %, of course depending upon design, material, bulk density etc. There is one collecting hopper where material gets collected. Smaller the diameter better is the efficiency.

Cyclone Separator

Get Price Quote

Cyclone Separator are designed for removing dirt, sand and solid particles from injection flow to mechanical seal. The separation is obtained by centrifugal force generated by differential pressure across the cyclone.

Cyclone Separator

Get Price Quote

we are offering cyclone separator are conical vessels attached to the seal gland for use with api plan 11 for flushing of the media to the seal chamber.industrial cyclone seprator is designed to supply clear flushing fluid for lubrication to mechanical seal in seal chamber. This is fitted in between pump discharge and seal flush port line, to remove abrasive particals which can cause damage to mechanical seal and reduce its recommended operational life.the heavy particles are separated with cyclonic effect & clean fluid is available for flushing the seal chamber in these industrial cyclone separator

Cyclonic Separation Trainer Model Env 001

350,000 Per Set

1 Set (MOQ)

Sci-tech Cyclonic Separation Trainer Model ENV 001 is a method of removing particulates from an air stream through a vortex separation process. A high speed forced vortex rotating air flow is established within a cylinder called a cyclone. Cyclones are used widely in sawmills to remove saw dust from extracted air as well as oil refineries to separate oils and gases. This Cyclone Separation Trainer is used for demonstrating the basics of cyclonic vortex separation. The apparatus comprises of four main cyclones of different diameters, a dust feed system and an air supply blower. A venturi type flow meter is provided to measure the incoming air flow rates. Each cyclone is fitted with a particle collector for dust collection. Cyclones can be run individually or in series of any two. Air flow rates can be varied by controlling the air blower speed. A dust tank is provided to inject the dust into the system. Differential pressure measurement for individual cyclones is provided to measure the pressure drop across the cyclone and hence the velocity of air in the cyclone can be determined. Sci-tech Cyclonic Separation Trainer Model ENV 001 trainer consists of three cyclone separators mounted on frame. Two cyclone separators are made of steel & one is made of glass. The cyclones can be arranged in such way that either one cyclone can be operated at a time, or two cyclones can be operated in series. A high-volume air blower which draws large volume of air through the cyclone separator. A hopper with control valve is used to feed dust particles into the stream of air. The air mixed with particles then enters tangentially at the top inlet in the separator. The dust particles are separated in the separator & collected in container at the bottom. The filtered air leaves the separator through the outlet at the top. A Variable Speed Drive is used to vary the velocity & flow of air through the separator. Each cyclone separator has glands to for measuring pressure difference across the cyclone. A differential pressure gauge is used to measure the differential pressure across cyclone. The air flow is measured by a venturi meter with differential pressure gauge. EXPERIMENTS CAPABILITIES • Understanding of air cyclone system. • Demonstration of basic cyclonic separation • Effect of input velocity against separation efficiency • Effect of particle size on separation efficiency • Cyclone diameter and conical construction on separation efficiency • Single and double cyclone operation effects • Comparison of pressure drop against input velocity • To verify the theoretical relationship between pressure drop and inlet velocity TECHNICAL DATA · Air Blower - Capacity 280 m3/hr @ 3400 RPM, - 5 hp 3 phase 415 V AC, 50 Hz - Static Pressure: 20 kPa - Blower Speed Control: Frequency Inverter · Cyclone Material: Stainless Steel or Borosilicate glass – 2 Nos, Borosilicate Glass -1 No. · Cyclone Separator: Diameter 100 mm – 1 Nos. · Cyclone Separator: Diameter 200 mm– 2 Nos. · Dust Collector: Acrylic tank · Dust Feeder · Air Flow Meter: Venturimeter with differential pressure gauge · No. of dust collector tank – 3 Nos. · No. of differential pressure gauges – 2 Nos. · Differential Pressure Range: 0-20 in of H2 · Instrumentation: Pressure drop: Manometer; Air flow rate: Venturi meter; Inverter for blower speed control · Digital Instrumentation a) 2 units of digital indicators. b) 2 units differential pressure transmitter for flow pressure drop · Mobile Steel Structure · Control Console: Coated Stainless Steel Optional v ‘Sci-Cal’ Computer Control Software & Interface (Please refer to Sci-Cal catalog) v ‘Sci-calVaq’ Sci-tech’s Virtual IoT based Data Acquisition system Please refer to Sci-CalVaq catalog)

Multi Cyclone Separator

Get Price Quote

The Manufacturers use the finest grade metal to manufacture Multi Cyclone Separator in standard weights. We make available the products using the exceptional quality raw material that is experts certified. This makes our product range completely reliable and genuine. Owing to the complete help of our dexterous staff, we present products that are certified as in conformance with the set norms.

Cyclone Separators

Get Price Quote

KERONE Manufacture Wide range of Industrial Cyclone Separator is acclaimed for its international quality standards. Our Cyclone Separator is equipped with advanced features that ensure its high operational effectiveness and quicker cleaning actions. The Cyclone Separator offered by us is designed with high capacity motor which helps in swift cleaning. Features Sturdy and long life Quick color change Powder bin cum hopper Less floor space occupation Easy maintenance. Applications Cement industry Powder conveying industry Abrasive industry Rubber industry

Cyclone Separator

Get Price Quote

Cyclone separators are normally used for the collection of coarse dust particles. The dust laden gases enter the separator under pressure or suction.

Cyclone Seperator

Get Price Quote

Centifugal Seperator, Cyclone Seperator & Sand Seperator Cyclone Separators are also known as Sand Separators or Centrifugal Separators. They require a minimum operating pressure of 2 kg/cm2. This filter does not contain any moving part or any filtration media hence there is zero maintenance and no choking of filter which leads to extremely low to zero pressure drop values.

Cyclone Separator

Get Price Quote

Cyclonic separation is a method of removing particulates from an air, gas or liquid stream, without the use of filters, through vortex separation. Rotational effects and gravity are used to separate mixtures of solids and fluids. The method can also be used to separate fine droplets of liquid from a gaseous stream. Dust laden gas or air enters the collector tangentially and follows a spiral path to the bottom of the cone. The centrifugal force created by the circular flow throws the dust particles toward the wall of the cyclone. After striking the wall, the combination of the gravitational and swirling forces causes the dust to move downward to the dust outlet. Pressure drop for normal operation is about 3 – 4 inches of water. They are very efficient in collecting dust particles down to 30 microns in size. Efficiency of the equipment depends on the material being conveyed, material/air flow rates, and cyclone design. Depending upon the application, cyclone separator can be designed in single, twin and quad arrangement and multiclone. Applications • Steel Industry Blast Furnace, Electric Arc Furnace, BOF, etc • Fertilizer Industry Phosphate Rock Dryers & Calciners, Dryers • Non-Ferrous Copper Reverberatory Furnace, Laea Blast Furnace • Pulp & Paper Lime Kilns, Back Liquor Recovery, Bark Boilers • Sugar Industry Boiler Flue Gas, Bagging Section • Mineral Products Asphalt Stone Dryers, Cement Kilns • Pharmaceuticals Tablet Coating Fans, etc

Accura Cyclone Separator

Get Price Quote

He acs is designed to remove sand, pipe scale and other abrasive particles from injection flow to mechanical seals. Separation is accomplished by centrifugal force generated by differential pressure across the cyclone.

Cyclone Separator

Get Price Quote

Vinayak�s Cyclone Separator is simple, low cost and efficiently designed for high performance. These are generally used for removing dry solid particle from air without the use of filters through vortex separation. We offer high quality Cyclone Separator that is appreciated by our clients across the globe. They are mainly divided into two classes: Single cycloneMultiple cyclone Working Principle : High speed rotating (air) flow is established within a cylinder and conical container to separate mixtures of solids and fluids. Air flows in a spiral pattern, beginning at the top inside the cylindrical shape and ending at the bottom inside the conical shape. Solid particle losses its velocity before exiting the cyclone from the top and solid particle gets collected at the bottom , only clean air exit from the center. Application : Rubber industriesPlastic IndustriesPharmaceutical industriesFood and related industriesChemical industries Benefits : Removing dry solid particle from air the use of filtersEasy to useLow operating cost

Cyclone Separator

Get Price Quote

The gas stream enters the Cyclone Separator tangentially. This starts a cyclone action throwing the liquids to the wall of the vessel. The gas comes down to the vortex finder plate, and reverses back up to the gas outlet pipe. In the centre of the vortex finder plate is a hole connected to the top sealed section by a recycle pipe. As the gas goes out, a low pressure area is created by the cyclone effect. This low pressure area is transmitted to the sealed section by the recycle line, and has a suction effect on the gap in the outlet pipe. Any remaining liquids are pulled through this gap and returned to the lower portion of the vessel by the recycle tube. These separators will remove 99.9% of all free liquids and solids 5 microns and larger when operated under design conditions.

Cyclone Separator

Get Price Quote

With the support of our advance infrastructural unit and diligent workforce, we are offering a customized assortment of Cyclone Separator to the clientele. Our Cyclone Separator is working smoothly with great capacity.

Cyclone Separator

15,000 Per Piece

1 Piece (MOQ)

Cyclone Separators

Get Price Quote

Cyclone Separators, Blowers, Centrifugal Blowers, Tube Axial Fan

Cyclone Separator

Get Price Quote

Cyclon Separator Series – CS 100 Performance Limits Maximum solid contents ………………… 15 % by weight Max. viscosity of Liquid……………………. 20 centistokes Pressure differential desired …………… 2 to 8.5 Kg Metal Parts Cyclon Separator Shell : Carbon Steel / SS 316/SS304 Secondary Seal : PTFE Specifications Size …….………………………. ½” NPT Design Pressure…….…… 180 Kg Working Pressure …….…160 Kg Max. Temperature …….. 200°C Cyclon Separator CS 100 improves mechanical seal life by cleaning the stream of process fluid to flush the mechanical seal. This is fitted in between pump discharge and seal flush port line, to remove abrasive particles which can cause damage the mechanical seal and reduce its recommended operational life.

Multi Cyclone Separator

Get Price Quote

Multi Cyclone Separator, Multi Stage Blower, High Temperature Fa

Cyclone Separator

Get Price Quote

Air Circulators, Scrubber, Roof Extractors, Industrial Fan

Multi Cyclone Dust Separator

Get Price Quote

Multi Cyclone Dust Separator, Acid Scrubber, PP Chemical Process Tank