Blow Moulds

Get Price Quote

Injection Molding Machine

Get Price Quote

The company furnishes highly advanced injection molding machine in the domestic as well as global market. The Plastic Injection Molding Machine supplied by us is backed with all kinds of modern and advanced features. These injection molding machines are manufactured from the quality base materials. They are used friendly in function and very durable in nature. They most important aspect of these injection molding machines are that they give hassle free operation with minimum maintenance. Besides, we offer these machines at the most discounted rates. Apart from that, we are one of the most reputed Injection Moluding Machines Manufacturers in India.

Best Deals from Molding Machine

Vertical Locking Horizontal Special Purpose Injection Moulding Machine

Get Price Quote

Vertical injection molding with vertical clamping & horizontal injection unit to reduce the height of machine in Higher Tonnage requirement. Insert Molding and Over Molding makes simple to produce with freedom in mold design and less risk of mold damages during production. Continuous automatic insert molding attachment is possible for high productivity

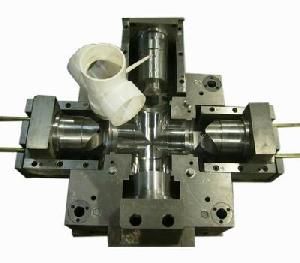

PVC Pipe Fitting Mould

250,000 - 800,000 Per Set

1 Piece (MOQ)

Manual Wax Injector

Get Price Quote

1 Piece (MOQ)

Two Color Injection Moulding Machine

Get Price Quote

MACHINE RANGE – 150 TONS TO 380 TONSSHOT WEIGHT – 91 GMS TO 294 GMS The TC-series, “multi-shot / multi-color†machines, are equipped with multiple injection units. For high production volumes, the series provide core or mold rotary tables with 180 degree rotation produces “multi shot / multi color†parts in one machine and provide mold support, guidance, and open / close movement in a rigid and long lasting design. The series have precise position setting and excellent functions to promote market, including electronic keyboards / switches , ball pen ( 24 cav.), tooth brushes (12 cav.) and the handles for tools.

Twin Cavity Auto Deflashing Blow Molding Machine

Get Price Quote

We have hired a team of experts who have developed a system for making safe and secure transactions. Our system has offline as well as offline options for payment. Our entire array of products is sternly manufactured using certified array of raw materials. These inputs are sourced only from trustworthy vendors present in the market.

Wax Injector

Get Price Quote

1 Piece(s) (MOQ)

We offer Wax Injector. Specifications:- Double Operator Double Nozzle. For storage of wax, a Solid Aluminum tank used. The outer body of the injector is made from M.S and powder coated. The transparent Acrylic top fitted with safety valve pressure gauge input valve. The thermostat utilized is of high accuracy range from 80C-100C0 and is made in Germany. FHB KB-30 Imported heater 500 watt is used for heating purpose. The entire tank is covered by 120 density ceramic - wool. Operating temp-720C. Operating voltage 230VAC Single phase. Machine is offered warranty for one year - no warranty for heater. Aluminum tank is provided for quick heating of wax. Wax Capacity: 2.5kg 3.5kg. Available with without manual pump. Pressure regulator provided with safety valve.

Injection Blow Molding Machine

250 - 2,500 Per piece

We are the leading Manufacturers & Exporters Of Machine Rubber Pads and Industrial Rubber Products

HDPE Blow Molding Machine

575,000 - 4,575,000 Per

PVC Pipe Fitting Moulds

Get Price Quote

To handle both automated inbound and outbound orders, we have exceptional warehousing solutions. We keep the wide array of products sorted in the warehouse to make sure that the delivery commences systematically. As we are acknowledged for providing high quality products to the clients, we make use of only superior grade raw materials as inputs. The selection of raw material is done by our experts.

Plastic Molding Machine

Get Price Quote

We have a well-developed all the in-house storage facility, laced with all the modern facilities. Also, we have hired a team of professionals who efficiently manage and maintain it. As we are acknowledged for providing high quality products to the clients, we make use of only superior grade raw materials as inputs. The selection of raw material is done by our experts.

Plastic Injection Moulding Machines

1,200,000 - 11,000,000 Per piece

Kindly attn:- Owner / Chairman / Director / Managing Director / Authorised Purchase Head.Dear Sir,We are mfg of new moulds and Are Sole Agents for sales and services provider for Indian market with Dealing of New Injection Moulding Machine Range from 100T to 4000T with having excellent quality and at most competitive reasonable prices & More Beneficiary for the exporters of finished goods.Machinery suitable for Injection Moulded products as for below1.Automobiles2.Battery case3.Furniture and crates4.Caps & Closures5.Computer & Accessories6.Household7.Electrical & Electronics8.Engineering9.Food & Non food containers10.Medical labs11.Paint pails12.Lubricants13.Pet performs14.Pipe fittings15.Textile16.Thin wall containers17.Writing instruments stationery18.Houseware & KitchenwareAnd having all ancillary equipment for support of injection,blow and extrusion plant machinery to run in automation are as1.Hopper & Dryer2.Auto loader3.Mould Temperature Controller (MTC)4.Granulator5.Colour Mixer6.Chiller7.Cooling Tower8.Robot 9.Cleaning Agent for Complete plant water system10.Hotrunner & Controller11.Preventive Maintenance for moulds & machinery12.Annual Maintenance Contract Pls to let us know the exact requirement of machinery1.What kind of product and raw material uses2.What capacity of machinery in Tonnage3.Total Shot weight4.Maximum Mould Size (L x W x Ht)5.Type Toggle or Hydraulic6.Min & Max Cycle time 7.Require Fixed pump or VDP or Servo8.How many quantity of Machinery require in nos. 9.Do you require New Moulds & design ready avail10.How many quanity new moulds require in Nos.11.Robot Require12.Require Ancillary equipment If any requirement pls feel free to provide us your valuable reply with appointment and contact name & numberAnd business visiting card. We provide complete services mfg for plastics industries from Plastics product to moulds to plastics machinery .Most Welcome Proposal for franchises partners & Investors & Buyers at State , district.Awaiting for your valuable feedback for project plan of purchase of capital goodsThanking you

Sheet Moulding Press

Get Price Quote

HDPE Blow Moulding Machine

Get Price Quote

Based on the skills of our dexterous workforce, we are offering quality assured hdpe plastic blow moulding machine. The offered machine is precisely manufactured using utmost-grade components and cutting-edge technology in compliance with the set industry standards. Features like consistent performance, low maintenance and high functionality rank our offered machine ahead of its competitors. This machine can be availed from us in various configurations at reasonable prices. Features : High strength Operational fluency Low operational cost

Dies & Moulds, Injection Blow Moulds, Press tool Dies, Fixtures, Machine Tool Maintenance

Get Price Quote

Machine Tool Engineers estd in the year 1996 is a proprietorship company based in Mumbai engaged in Machine Tool Manufacturing, Dies & Moulds, Injection Blow Moulding ,Special Purpose Machines Rebuild and Repairs & all types of Machining work

Auto Clamp Wax Injector

105,000 Per Piece

1 Piece (MOQ)

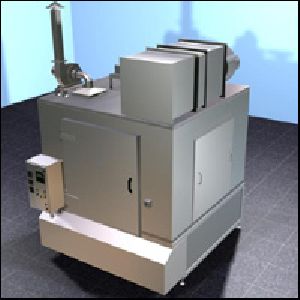

Chocolate Mould Cleaning Machine

Get Price Quote

Chocolate mould cleaning machine is specially designed to clean the tough residues of chocolate in the mould. Batch type process Multistage High pressure spray cleaning Spray rinsing Hot air blow Totally stainless steel construction. Continuous fresh water rinsing.

Rubber Injection Moulding Machine

Get Price Quote

We are pleased to provide latest Rubber Injection Moulding Machine that is manufactured using highly automated parts. Our machine can perform the entire process starting from raw material feeding, injecting, plasticizing, forming to the withdrawing of the finished product. Liquid Silicone Rubber Injection Moulding Machine, we deliver, is characterized by high performance and low maintenance. We have made untiring efforts to combine quality with most reasonable price and this has brought us among the most celebrated Industrial Rubber Moulding Machine Manufacturers. Rubber Moulding Press : We are offering heavy-duty multi day light hydraulic press is suitable for rubber, plastic, bakelite, lamination & wood pressing jobs. it can be used for different processes such as bending and straightening plates, cutting, embossing & drawing. Â Heavy Duty Hydraulic Press : Offering heavy-duty multi day light hydraulic press, suitable for rubber, plastic, bakelite, lamination & wood pressing jobs. It can be used for different processes such as bending / straightening plates, cutting, embossing & drawing. Â Rubber Injection Molding Machines : Santec' is pleased to announce that we are going to launch state of the art technology based fully Automatic "Rubber injection moulding press". He live demonstration of the machine can be seen at forthcoming "India-Rubber Expo-2005". Â Rubber Machinery : Offering rubber processing machines like rubber mixing mills, dispersion kneader, extruder machines and calendar machines. Â Rubber Machinery and Rubber Processing Machinery : Selling rubber processing machines like rubber mixing mills, dispersion kneader, extruder machines and colander machines. Â Rubber Mixing Mills : We are offering rubber mixing mills with following specifcations : It is an essential laboratory equipment in the plastic & rubber processing industries. Safety Features : Built-in driving unit, less space requirement, 6 pole electric motor. Quantity : Any

Bladder Moulding Press

Get Price Quote

Technical Description The SBV Bladder presses are designed especially for manufacturing and curing the bladders use in the AUBO, BOM & AUTOFORM presses. The control of hydraulic system included in the equipment is designed such that the lower mould half carrying the uncured rubber approaches the upper mould half with high velocity during the first closing stage, reducing the total closing period to minimum. In the beginning of the pressing operation, the closing speed is slackened automatically in order to obtain slow and uniform compression of uncured material. After laps of the curing time, the press opens up automatically and the bladders for AUBO and BOM presses are removed from the lower core plate. The bladders for AUTOFORM presses are detached by a pneumatic device which is included in the delivery on request. The moulds which are generally executed according to customers drawings are made of high grade steel. The two external mould portions and the core are cured by a direct steam connection. The presses and hydraulic power unit are delivered, complete and ready for connection, excluding curing platens. A timer for automatic press opening after termination of the curing period as well as steam and condensate piping are normal features of supply. Supervision of erection, installation and commissioning. Machine Features The press is complete with all ancillaries necessary for the proper function of the bladder moulding operation and provided with terminations for appropriate connection by others to the battery limits of site services. The press is equipped with a mould lifting fixture and removable mould roll-in, roll-out table to facilitate mould changing. All components of the press structure, hydraulic system and associated items of the plant are designed so as to safely carry all loads imposed by the use of the press moulding Tyre press bladders and rated for the maximum design press closing force. The press structure is designed to safely carry a normally imposed load of at least 15% excess of the designed maximum closing force. The hydraulic system is designed so as to deliver a maximum of 5% excess of closing force above the design maximum closing force. All electrical equipment is suitable for connection to the site electricity supply at 440 volts, 3 phase & neutral 50 Hz, control voltage to be 110 volts, 50 Hz, single phase from panel transformer. Included Items One hydraulically operated bladder moulding press complete with main RAM for applying varying press closing forces & auxiliary RAM systems for mould core and ring movements together with means of locating and retaining mould cores, upper & lower mould halves in the press and suitable for a range of tyre press bladder mould sizes up to the maximum sizes and rated for the maximum design press closing force. One electric motor driven hydraulic power unit continuously rated to provide varying press closing forces for moulding. One complete press control system complete with all valves, controls, instruments, gauges and actuators necessary for the safe operation of the press and the control of the moulding operation including recording of cure cycle time, temperature & operating parameters recording when moulding a range of tire press bladders. One Electrical control cabinet to house all items associated with electrical control system complete. One set of compressed air pipe work and fittings for supply of air requirements which is to include air rectification units to remove fine entrained contaminants and droplets, an air receiver to continue the operation in the event of a compressed air supply failure & for removal of cured bladder at the end of cure, pressure regulation to the requirements of recorder / controller is to be provided together, the site battery compressed air limit at (7) kg / cm3. All necessary drawings, details and general assistance to enable others to prepare foundations & other installation requirements will be provided with the machine. Additionally Spare parts list for normal two years operation. Training of three engineers (operation, maintenance, quality control). The supervision of erection, installation and commissioning will be provided at an additional cost. We guarantee that the equipment when correctly mounted properly operated and maintained, shall give satisfactory performance for a period of 12 months from the date of start-up.

PVC Moulds

Get Price Quote

1000 Kilogram (MOQ)

We manufacture high quality pvc moulds for paver, tiles, and other precast items. These moulds made keeping in minf the different conditions the mould has to go through during the manufacturing process of the precast product. Our team also designs precast products according to the needs of the customer.

Stretch Blow Moulding

Get Price Quote

PET packaging requires new technical solutions every day in the constantly changing world of plastic packaging. We are ready to satisfy the specific needs of each client with solutions that are specific to each case, attentive to every detail. To make you easier to find which of our blowers PET preforms best fits your needs, this comparative table will give you clarity. Please send us request via adjacent form for more information to help you on best option to suit your need.

Injection Moulding Machines

Get Price Quote

We offer injection moulding machines and moulds. State-of-the-art microprocessor controlled plastic injection moulding machines. The injection moulding machine ranks among the company's many winning products.

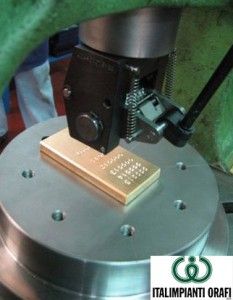

Mold for Ingots and Numbering Equipment

Get Price Quote

Molds and for ingots numbering equipment: • Numerazone with mold and manual rocker • Several models of rockers

Rubber Moulding Hydraulic Press

Get Price Quote

Stretch Blow Moulding Machine

Get Price Quote

We supply wide range of Stretch Blow moulding machines designed for high performance and easy to operate suitable to produce different shapes of PET/PC/PP/PE bottles. It can blow from 100ml-20Ltrs bottles widely used to produce mineral water, carbonated drinks, juice,medicine,cosmetic and Oil bottle etc.

Mould Vulcanizer Machine

Get Price Quote

We are the main supplier of this product.

Injection Molding Machine

Get Price Quote

Leveraging upon our efficient team of procurement agents, we have acquired a foremost position in the Indian and international markets as the Exporter and Supplier of the Injection Molding Machines of the best kind.

Blow Molding Machines

Get Price Quote

SMART Extrusion Blow Molding Machines have Smallest Footprint in the Industry and are Custom Built to be suitable for various applications. The Main Features of SMART Extrusion Blow Molding Machines are as under : Single or Double Station Microprocessor Controls Helical Gear Box Larger Mould Area Superior Mixing Screws Continuous Parsion A.C. Drive Fast Dry Cycle Energy Efficient User Friendly Features : Single or Double Station Microprocessor Controls Helical Gear Box Larger Mould Area Superior Mixing Screws Continuous Parsion A.C. Drive Fast Dry Cycle Power Saver User Friendly

Semi Automatic Blow Moulding Machines

Get Price Quote

We provide semi automatic blow moulding machines to our clients. These machines are manufactured using optimum quality material and can be availed from us in various sizes and specifications as per clients' requirements. Our machines are used in manufacturing of bottles, pet jars, plastic jar, plastic bottles, mineral water bottles and mineral water jars. We provide these machines at pocket friendly prices within the predetermined time-frame. Features: long functional life, corrosion resistant,tensile strength.