IBR Steam Boiler

Get Price Quote

1 Piece (MOQ)

IBR Wood Fired Steam Boiler

650,000 Per Piece

1 Piece (MOQ)

IBR Wood-Fired Steam Boiler Chhoker & Sons is the finest IBR wood-fired steam boiler trader, serving customers with advanced technology and the best-quality raw materials. Our steam boilers are highly recommended for their durability and quality. With our team of talented professionals, we are capable of providing these products in compliance with the global standard. Our products are available at competitive prices. The offered IBR Wood-Fired Steam Boiler is flawlessly processed according to market standards by using quality-assured materials and advanced tools and technology. Our products are easy to assess in assorted specifications and can be changed according to the demands of the clients. At the same time, we also accept customised orders from customers. Wood is used as a fuel here and has a capacity of 1000–2000 kg/hr. You can place your order online and get faster delivery.

Best Deals from IBR Steam Boiler

IBR & Non IBR Flanges

Get Price Quote

10 Piece (MOQ)

IBR Flanges we offer belong to inventory having wide ranging options of size, shape and fabrication material. The production facility allows us to design and fabricate non IBR flange in India as per the requirement of our customers. Size : 1/2"NB TO 60"NB IN Class : 150 LBS, 300 LBS, 600 LBS, 900 LBS, 1500 LBS, 2500 LBS, DIN Standard ND-6,10, 16, 25, 40 Etc. Type IBR Weld Neck, IBR Â Socket Weld, BR Â Slip On, IBR Blind, IBR Lap Joint, IBR Screwed (Threaded), IBR Long Weld Neck, IBR Reducing, IBR Ring Joint, IBR Orifice, IBR Girth Flange and many more. We provide IBR and non IBR Flanges as per the INTERNATIONAL STANDARD ASTM, ASME, API, AISI, BS, ANSI, DIN, JIS, MSSP, NACE IBR Alloy Steel Flanges ASTM SA 182 F1/F5/F9/F11/F22/F91 IBR Carbon Steel Flanges ASTMA 105 Gr. F42/46/52/56/60/65/70 IBR LTCS Flanges A350 LF2/A350 LF3 IBR Forged Fittings Size : 1/4"NB TO 4"NB IN

IBR Steam Boiler

Get Price Quote

Manufacturer & Exporter of Steam Boiler & Accessories water wall panel, Air Pre Heater, Economizer,

IBR Steam Boiler

50 - 10,000,000 Per KGS

1 Piece (MOQ)

Three Pass Fully Wet Back Solid Fuel Drop Feed Type IBR Steam Boilers

Get Price Quote

Disel Fire IBR Steam Boiler

Get Price Quote

IBR Steam Boiler

Get Price Quote

Available in the range of 100 KGS TO 1000 KGS/HR, our IBR Steam Boiler is the name you can trust on for industry specific boiling application. Being semi-automatic in functioning, IBR Steam Boiler is one of client’s favorite Industrial Boilers. IBR Steam Boiler has a Wood Fired Smoke Tube Type Three Pass IBR Design. Our IBR Steam Boiler is also widely preferred for it being fully in compliance with the standards laid by the industry.Details : Excellent finish User friendly Steady steam supply Reasonable price Semi automatic

IBR Steam Boiler

Get Price Quote

We are situated in Delhi(India) and we have a well-developed network that assists us in reaching any destination. Our company has worked hard to establish an efficient distribution network. Therefore, buyers can order the product in mass and expect on time delivery.

IBR Steam Boiler

4,000,000 Per Set

1 Set(s) (MOQ)

We Manufacture SMOKE TUBE or FIRE TUBE Oil Gas Fired Steam Boilers up to capacity of 16 TPH with steam pressure up to 25 Bar. The Boilers are Manufactured under Inspection of IBR ( Indian Boiler Regulation) or alternatively can also be manufactured under LLOYDS Register ( LR ) , BVQI or any other Inspection Agency authorised by IBR and acceptable to customer.

IBR Steam Boiler

Get Price Quote

ENERGYPACK -IBR Steam Boilers in Maharashtra, manufactured by us are designed as per latest Indian boiler regulation & others code like BS or ASTMA. Capacity from 500 kgs/hr to 14,000 kgs/hr for the process industries.

IBR Steam Boiler

950,000 Per Ton

I would like to introduce our company brij industries that has been in boiler, chemical treatment plant & wooden seasoning plant business for the past 23 years. We are a verified supplier of indiamart. We have been an established and popular company with an excellent track record for the best customer satisfaction. We have never compromised with the quality and the services provided to the customer. We believe in keeping the customers happy and providing them with the products at a very competent price. We have an excellent staffs who will guide you with their best ideas by keeping in touch with your company and informing about the market trends.

Smoke tube IBR Steam boilers

Get Price Quote

Salient Features Large Heating Surface area and furnace with high radiant heating surface maintain furnace temperature below the permission limits. Thermal efficiency is 87% ± 2 Optimum flue gas outlet temperature. Superior combustion efficiency. Fully automatic burner Hi - Tech / Imported, On-Off, High Low type. Furnace oil pre heater ( in case of heavy oil )

IBR Steam Boiler

Get Price Quote

IBR Steam Boiler

Get Price Quote

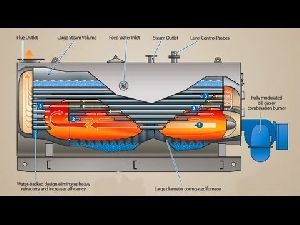

IBR Steam Boiler are Engineered for maximum safety, highest efficiency, dependability and quit operation. Wet back Models eliminate rear end refractory and its inherent maintenance cost, reduces stress of rear tube sheet and ligament cracking, radiant heat is eliminated, lengthening tube life and reducing heat loss from rear turn around.

Gas Fired IBR Steam Boiler

Get Price Quote

We are leading manufacturer, supplier, dealer & exporter of gas fired boilers. We provide a wide range of top quality gas fired steam boilers. These products are commonly used in various industrial purposes where constant supply of steam is required.

IBR Steam Boiler

Get Price Quote

IBR Steam Boiler are equipped with large heating areas and large content of co2 burners, which helps in maintaining clean combustion. Fabricated with the most advanced technologies and high grade raw materials, these products are highly recommended for premium quality and durability. In addition, these products are available in competitive prices.

IBR Steam Boiler

700,000 Per Piece

Oil Fired IBR Steam Boiler

Get Price Quote

We are a trusted name of the industry engaged in manufacturing a premium quality range of Oil Fired Steam Boiler. Our offered products are equipped with large heating areas and large content of co2 burners, which helps in maintaining clean combustion. Fabricated with the most advanced technologies and high grade raw materials, these products are highly recommended for premium quality and durability. In addition, these products are available in competitive prices Feactures :- Fully automatic 88% thermal efficiency Smooth operation Completely safe and no explosion hazard Low maintenance

IBR Steam Boiler

Get Price Quote

Solid fuel fired with fully wet back design IBR Steam Boiler are Offered in Coal, Wood. These boiler are 3 pass horizontal shell type integral furnace, flue tube, solid fuel fired high Efficient boiler. This boiler is fully wetback, packaged boiler, conforming to the latest revisions of Indian Boiler Regulations. (IBR-1950). These boilers are offered in various capacities of up to 2 TPH and working pressure of up to 10.54Kgs/cm2 Salient Features:• Maximum possible absorption of radiant heat • Avoidance of flame impeachment on the rear of the furnace. • Prevention of clinker formation. • Enhanced life of furnace. • Low cost heating, trouble-free operations & long-lasting • Available with fixed grate and rocking grate furnace • Available in shell & smock tube types • Works on natural proper water circulation • Provided with ID fan for maintaining to draught • Safety valve, steam stop valve, water level gauge glass & control • Switches mounted on the boiler • Multi-fuel option coal/lignite/wood/brickets.

Coil Type IBR Small Industrial Steam Boiler

Get Price Quote

Fully automatic Coil Type LDO/Diesel/FO and Gas Fired IBR – Small Industrial Steam Boiler » Fully Automatic Packaged Design » “Reverse Flue” Design » Forced Circulation Coil Type » Four Pass IBR Boiler » High efficiency Low Operating cost » Easy conversion » Instant steaming » Fully equipped with set of Safety Device » More Power Saver

Ibr Steam Boilers

Get Price Quote

Our clients can avail from us an exclusive range of IBR steam boilers that are available in two models, namely Three Stage Vertical Tube and Four Stage Vertical Tube.Available with us are IBR Steam Boilers that are ideal for several kinds of dry steam applications. Offered at competitive prices, the IBR Steam Boilers offered by us have horizontal construction. Mentioned below are some of the highlighting features of our IBR Steam Boilers

Oil Gas IBR Steam Boilers

Get Price Quote

Type : Three pass horizontal, smoke tube, fully wetback, packaged boiler, conforming to the latest revisions of Indian Boiler Regulations. (IBR) Capacity : 1000 to 25000 kg/h F & A100º C Working Pressure: 10.54 / 14.5/ 17.5kg/cm2 (g) and above. Fuel : LDO / FO / Gas / Dual Fuel (Oil cum Gas) Thermal Efficiency : 88 ± 2 % without heat recovery unit and 92 ± 2 % with heat recovery unit based on NCV of fuel oil. Burner : Fully automatic pressure jet (high - low / stepless modulation ); indigenous / imported burners. The combustion chamber (furnace) forms the first pass in which the fuel is atomized, combusted and radiant heat transmitted to the water contained in the shell, submerging the furnace, reversing camber and smoke tubes. The hot flue gases are diverted through the internal reversing chamber (wetback) and subsequently to the second and third pass of tubes transferring the convective heat to the boiler. The boiler is of Class 1 fusion-welded construction. Burner & Boiler Controls The burner programmer ensures an automatically controlled programme for start-up, firing, shutdown and restart of the boiler based on measurement of boiler pressure. Necessary interlocks are provided for safe operation. The water level is controlled through Mobrey type dual controller which is a magnetically operated water level controller of vertical type in a float chamber and is externally mounted on the boiler. One switch of the dual controller operates the electric feed pump on/off. The second switch cuts out or locks out the burner in case of low level of water and at the same time operates a low level alarm. The boiler is provided with one high pressure cutout switch and one additional pressure switch for high/low, or continuous modulation of operation. Salient Features MAXITHERM has adopted the modern concept of eccentrically located furnace with smoke tubes arranged in a staggered manner on one side of the furnace. The front and rear tubes and the furnace are accessible for inspection and maintenance. Generously proportioned furnace with large furnace volume ensuring; Maximum possible absorption of radiant heat. Avoidance of flame impeachment on the rear of the furnace. Prevention of clinker formation. Enhanced life of furnace. Adequate water and steam spaces enable the boiler to meet fluctuating loads with out appreciable fall in the operating pressure. This also ensures prevention of priming, foaming and carryover of the boiler water into steam pipelines and further ensures steam with high dryness fraction. The eccentrically located furnace has the following advantages :- Easy accessibility to the outer surface of furnace for inspection and scale removal. Possibility of providing single smoke box, which when opened makes all smoke tubes accessible for cleaning. The burner is mounted directly in font of the furnace, facilitating opening of the front door to clean the tubes without disturbing the burner.

IBR Steam Boiler

Get Price Quote

Capacity : 5 TPH up to 100 TPH, Pressure : up to 100 Bar, Fuel : HSD LDO Furnace oil Natural Gas LPG.

IBR Steam Boiler

Get Price Quote

We are apex in the list of companies imparting the wide assortment of WoodOil Husk LDO fired Non-IBR Steam Boiler for the clients. These Vertical Non-IBR Steam Boiler s are manufactured with the premium quality of raw material procured from the authentic vendor base. Our Non IBR Steam Boilers widely earn accolades for their durability and superior quality and this help us to serve the both small and medium scale plants. Our priorities are client satisfaction so we offer the products that suit best to the firm. We do hold the capability of customizing the entire ranges as per the specification laid down by the client. Medium and high capacity Non-IBR Boilers also come with Super-Heater for producing dry steam.

IBR Steam Boiler

Get Price Quote

Shree Laxmi Engineering is in design, engineering, and supply of IBR Steam Boiler of various capacities. We believe in offering highly efficient boilers. We believe, boiler is a heart of industries and would strive to provide best accessories with the boilers manufactured by us. We would offer various burners like saacke, weishaupt, nuway, riello burners with our boilers to ensure best combustions efficiency. Selection of burners is based on our customers preference & service support available in the region of installation. We are, in the process of getting IBR license for manufacturing of boiler's as per IBR guidelines. IBR follows ASME code for construction of steam boilers. IBR - Indian Boiler Regulation is a nodal agency appointed by Indian government to ensure boiler manufacturing and use in industries. Features : High performance Long performing life Smooth functioning

IBR Steam Boiler

Get Price Quote

Range 100 to 600 KGHR. » Water tube construction. » Thermal Efficiency 86 ± 2% on NCV. » Coil from Seamless ASTMA 106 GR-B Pipes. » Instant steam generation. » Easy & Economical Operation.

Solid Fuel Fired IBR Steam Boilers

Get Price Quote

Capacity: 300 kgs/hr and above. Type: horizontal, shell type smoke tube boiler. Fully automatic, three pass wet back design. High efficiency 75±2 [NCV]. Fitted with all safety and indigenies accessories. Can be designed to meet customer specific requiremts.

IBR Steam Boiler

Get Price Quote

Packaged Boiler: Widely used in different industrial areas and engineering plants, are assured of precise dimension and smooth operation The packaged boiler is so called because it comes as a complete package. These are available in different specifications as per the requirement of the clients Once delivered to site, it requires only the steam, water pipe work, fuel supply and electrical connections to be made for it to become operational. Package boilers are generally of shell type with fire tube design so as to achieve high heat transfer rates by both radiation and convection The features of package boilers are: Small combustion space and high heat release rate resulting in faster evaporation. Large number of small diameter tubes leading to good convective heat transfer. Forced or induced draft systems resulting in good combustion efficiency. Number of passes resulting in better overall heat transfer. Higher thermal efficiency levels compared with other boilers. These boilers are classified based on the number of passes – the number of times the hot combustion gases pass through the boiler. The combustion chamber is taken, as the first pass after which there may be one, two or three sets of fire-tubes. The most common boiler of this class is a three-pass unit with two sets of fire-tubes and with the exhaust gases exiting through the rear of the boiler.

IBR Steam Boiler

Get Price Quote

1) Fully automatic instant steaming. 2) Easy operation fail proof system. 3) Record efficiency. 4) Packaged models in unitised design.