Wheel Balancing Machine

160,000 Per piece

1 piece (MOQ)

2 display window,Adopt high quality computer feature of high intelligence and high stable,Mechanical main shaft adopt high precission bearing, wear resistant, low noise,Self calibration & fully automatic trouble diagnosis,Automatic stops,Hood start & ALU function.

Balancing Machine

Get Price Quote

The basic materials that we use for the manufacturing of our entire range are thoroughly checked against numerous quality parameters. Thus, we make sure that we deliver faultless products to the clients. Our payment procedures are hassle free, safe, and legal. We do not impose hidden charges while creating the invoice and ensure your money is transferred securely from you to us.

Best Deals from Balancing Machine

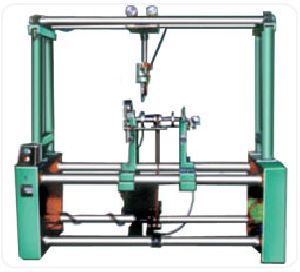

3 ARM Tool Balancers

400,000 - 1,500,000 Per Set

1 Set (MOQ)

Tool Dynamic TD Economic Modular Balancing System

Get Price Quote

1 Unit piece (MOQ)

Field Balancing Machine

Get Price Quote

Dynamic Balancing Machine

100,000 - 1,000,000 Per Piece

1 Piece(s) (MOQ)

Easily detects an imbalance of less than 0.1g on small parts whether the part weighs 50 g or 8 kg Soft bearing balancing station. Light enough to move without special equipment Self-sufficient. No additional computers required Requires no PC or programming knowledge to operate Help prevent spindle bearing damage and thus lowers operating costs Balances every tool or wheelsetTool balancing increases tool life and improves tool performanceWheel balancing increases wheel life and produces a better surface finish and cutting edge on the tools you grind An MPM balancing system will not only help you grind better tools, it will also reduce grinding wheel wear and machine repairs. balancing improves the mechanical stability of your grinding machine and reduces stress on the grinding spindle.

Dynamic Balancing Machines

Get Price Quote

with Microprocessor Based Measuring Panel ( Hard Bearing Model - HDCM ) Machines model HDCM are belt driven horizontal type photo scanning Universal Hard Bearing Balancing Machine, provided with microprocessor based measuring panel HDCM – 8500 suitable for balancing different shapes of rotors, of electrical machines, Cylinders, fly wheel, rotor of centrifugal pumps and other type of rotating machines. These machines are very simple in design. No drive coupling / adaptor etc. required to connect to the rotor to be balanced. It has following advantages - Cost saving on manufacturing of precision adaptor to connect drive coupling to rotor. Any rotor can be balanced without losing time in manufacturing of adaptor. The balancing accuracy of rotor not disturbed due to unbalance in drive coupling / adaptor. Belt drive machine are more accurate (about 5 times) as compared to end drive machine. The machines features a very simple operation. The working cycle is fully automatic. From safety point of view a double press push button starts machine, Measures and stores the unbalance values on DPMs for two Plane simultaneously and stops machine. Key board facility provided in measuring panel for correct data feeding of rotor with 1 digit accuracy for its dimensions like A, B, C, R1 & R2. Tolerance limits of both correction planes i.e. +11 & +12 can be feed so that when rotor is balanced within the limits respective LEDs glow up, indicating no further correction necessary. For other details please refer “ features of measuring panel HDCM-8500” Standard Features : Digital display for unbalance indication Amount and angle for unbalance for both planes displayed on separate DPMs. Hence linear accuracy is very goos as compared to analog meter +digit for amount and + degree for angle. Digital display for RPM indication A DPM is provided to indicate balancing speed continuously as a standard feature. Auto Stop No necessity to stop machine once started. It stops automatically after stabilization of unbalance results. Simultaneous Indication Amount and angle of unbalance in both planes displayed simultaneously and remains displayed (stored ) till next run. This totally eliminates operation of plane selector and reduces additional time for stabilization of readings in other plane. Key-Board Data of rotor dimensions and balancing tolerance i.e. values of A, B, C, R1, R2, t11, t12 are fed by key operation. Hence accuracy of data feedings accurate up to 1 digit. Tolerance Indicators Separate LEDs are provided for both planes which glow when unbalance is reduced within balancing tolerance. Auto Range Depending upon whether unbalance amount is more or less a respective course or fine range gets automatically selected till rotor gets balanced within tolerance limits, Multiplier operation is totally eliminated. Data store Data is provided with 'Self check' mode which checks proper functioning of digital display. LED's is cycle operation. This helps immediate fault detection. Self Check Panel is provided with ‘self-check’ mode which checks proper functioning of digital displays, LEDs is cyclic operation (optional). This helps immediate fault detection. Additional Featureson demand : Printer : A matrix printer can be connected through ‘FIE’ software. It shows runs till rotor is balanced within balancing tolerance. Component Indication : ‘FIE’ software specially developed with 3-99 component indication, is suitable for balancing of rotor with fixed locations for balancing correction. Unbalance Correction : Drill attachment 8mm capacity portable drill with supporting overhead railing. Separate drilling attachment 19mm. Capacity with a vertical drilling head , manual. Portable type reveting hammer (piston type) speed 1800 blows/minute, capacity 6mm in a aluminum suspected from top with rail. Tangential belt drive, in addition to standard (suitable for a particular type of rotor for production balancing) Longitudinal movement of right hand pedestal by chain & sprocket attachment. • The balancing speed depends upon selection of the rotor diameter, where drive is to be given and the motor pulley diameter. • All the machines above operate on mains supply of 400 to 440 V, 3Ø, 50 cycles. • Due to constant R & D, specifications and features are subject to change without notice. The dimensions given above are approximate.

Counter Balanced Smith Machine

Get Price Quote

Advanced design accommodates lightweights and heavy lifters. Ideal machine for beginners. Engineered with racking pegs for 10-weight bar adjustment. Olympic Bar travels at 5-degree angle on linear bearings for smooth operation. Counterbalance system allows lifting the actual weight and making zero bars weight. Multi exercise can be performed in this machine. Extra feature of shroud is provided to make the machine dust free and to look elegant. Dimension: 1480 x 1200 x 2150

Vertical Balancing Machine

Get Price Quote

Manufacturer of a wide range of products which include Fan Vertical Dynamic Balancing Machine, Clutch Cover Machine, Drill Unit Machine, Brake Drum Machine, Fan Machine and Vertical Balancing Machine.This machine is used to remove the unwanted vibrations from the Fan.

Dynamic Balancing Machine

Get Price Quote

We are the leading Manufacturers and Suppliers of Dynamic Balancing Machine in Pune, Maharashtra, India. Machines Model HDM are horizontal type universal hard bearing balancing machines provided with Microprocessor based measuring panel HDM- 8500 for balancing the different shapes of rotors, like rotors of electrical machines, crankshafts, cylinders, Gas Compressors, flywheels, turbine rotors, centrifugal pumps, and any other type of rotating machine. These machines feature a very simple operation. The working cycle is fully automatic. From the safety point of view, a double press push button starts machine measures and stores the unbalance values on DPMs for two planes simultaneously and stops the machine ( with a break if machine is provided with an electrical breaking facility.) The measuring cycle, in general, is less than 10 seconds for normal rotors, which can be accelerated within 5 seconds.

Dynamic Balancing Machine

Get Price Quote

Wheel Balancing Machine

65,000 Per Piece

Dynamic Balancing Machine

Get Price Quote

Model - HDM & HDCM Horizontal type universal hard bearing machines. Various models - Suitable for Rotor from 0.5 kg. to 10000 kg. Good for precision balancing upto 0.2 micron shift. Computerised model available.

Tool Balancer

Get Price Quote

The balance function has been added to the hose reel so you can control the vertical position of air tools and similar equipment effortlessly. The balancer can be used as both a suspension wire and air hose, eliminating untidy difficult to organize tubing. The casing and drum are made of a special synthetic resin and are built to be tough and lightweight. The hose is made of high-quality urethane and is highly durable. The air tube has a diameter of Φ9mm at the inlet portion and an Rc14 female union at the outlet portion.

Vertical Balancing Machine

Get Price Quote

oise & Frequency Analysis There are many cases, where high vibration amplitudes are not caused, only by rotor unbalance. In such cases vibration Analyzer (with tracking filter section) covering broad frequency range, can offer specific 'SINGNATURE' of rotating body to identify the Sources of vibrations. This helps to conclude the Source of Vibration like : 1) Misalignment 2) Bend shafts 3) Gear backclashes etc. 4) Worn out bearings & Surfaces 5) Weakness of Foundation Structure

Vertical Balancing Machine

Get Price Quote

Global Single Vertical Balancing Machine Market research report gives a systematic and competent approach to gather important statistics of Global Single Vertical Balancing Machine industry. In which includes industry chain structure, Single Vertical Balancing Machine market classification, dominant market players, product definition, and product scope. Global Single Vertical Balancing Machine Market research report also interprets different market scenarios along with future market trends. Global Single Vertical Balancing Machine research report performs SWOT analysis to gain better insights on Strengths, Opportunities, and Threats muddled in Single Vertical Balancing Machine industry. Single Vertical Balancing Machine Market dynamics, production capacity, consumer volume, supply to demand ratio, Single Vertical Balancing Machine market share and revenue is also deliberated in this research report.

Balancing Machine

80,000 - 85,000 Per UNIT

1 UNIT (MOQ)

Balancing Machine, WHEEL ALIGNMEN

Wheel Balancing Machines

Get Price Quote

Wheel Balancing Machines, Automobile, Garage, Mechanical Equipmen

Tool Hose Balancer

Get Price Quote

Tool Hose Balancer, Chamfering Auto Feed Unit, CNC Dril

Dynamic Balancing Machine

Get Price Quote

Dynamic Balancing Machine, Boilers, CNC Machines, Rubber Hoses, Terry Towe

Dynamic Balancing Machine

Get Price Quote

Dynamic Balancing Machin

Auto Balancing Machines

Get Price Quote

Auto Balancing Machine

Field Fabricated Balancing Machine

Get Price Quote

Field Fabricated Balancing Machin

Dynamic Balancing Machine

Get Price Quote

Dynamic Balancing Machine, Inflatable Tube, Flange Yoke, Tube Yok

Balancing Machine

Get Price Quote

Balancing Machine, AC Recovery Units, Extraction Syste

Balancing Machine

Get Price Quote

Balancing Machine, Shrink Fit Machine, Tool Holder, Display Ite

Portable Balancing Machines

Get Price Quote

Portable Balancing Machines, Vibration Analyze