Wire Saws Plant

Diamond Segments For Saws , Wire Saw Or Gang Saws. Comprising Of Powder Mixing Cold , Compacting , Hot Sintering , Brazing Etc. Machines Upto 120 Tons And Hot Sintering Machines 120 Kva 40 Tons With Vacuum Are Available .

...more

Volumetric Cold Compacting Press

Latest trend to increase the output production rate with automation made us to manufacture the volumetric cold compacting press . Hopper is filled with granulated powder with diamond grit of the required proportion . Initiation of cycle put hydraulicpnuematic cyclinder ,fill the powder in the cavity (diespunch as per customer's need) followed up by pressing by top cylinder position ,ejector lifts up the cold compacted segment. This is automatically pushed into the tray provided , simultaneously filling the cavity with new powder and auto cycle continues. Change of diespunch is very easy and doesnot take more than 20 minutes these process are manufactured into 2 different standard models of 5 tonnes & 12 tonnes with following specifciations.

...more

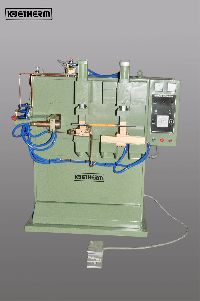

UPSET BUTT WELDER

Weld quality obtained is mechanically and metallurgically similar to the parent metal . Because of shorter weld times the process is suited for higher production than other conventional methods .No additional material such as rods or gas etc. are required , thus It is highly economical. The machine cycle involves heating ,upset butt welding followed by flash removal by special molybdenum alloyed inserts.

...more

spot cum projection welder

All operational controls - air, water and solid state electronic - are machine mounted, for easy access, safe and simple maintenance. Weld sequence controller, sophisticated Quartz timer with squeeze, weld, hold and off timings with singlerepeat cycle facility, weld timing being controlled by Thyristor circuit, heat controllable from 5% to 95%. Electrode cushion control adjusts the descent of the upper electrode to any desired speed and completely eliminates 'hammer blow'. Sturdy ram assembly permits high speed operation.

...more

Seam Welder

Thyristor controlled electronic timer with electronic heat control, to give heavy duty high speed operation, providing smooth, stepless and accurate adjustment of the welding current. High quality roller bearings carrying the roller shafts, guaranteed longer-life of the roller heads. Leak proof joints at much lower costs than conventional welding.

...more

screw presses

Application Includes Forging Of AllenHex Bolts , Valves And Other Auto Components Range :- 50 Tons To 400 Tons. In Both Versions Up-Stroke As Well As Down-Strok

...more

Powder Mixing Machine

Powder of various elementscompounds such as Cobalt, Tin, Silver, Tungsten metal , Tungsten Carbide etc. are weighed along with requisite diamond grit. These are then put in stainless steel jarscans which are then loaded on the mixing machine. Mixing machine when Put On runs for predetermined time through programmable timer planned which runs the machine. It allows all the powders put in required proportion depending upon the bond selected to uniformly mix and become amalgamated as required for further process of compacting and hot sintering.

...more

powder compacting machine

Wide ranges of powder compacting presses are manufactured from heavy steel plates. The min. frame is fabricated from plates & thereafter they are stress relieved. The presses are designed in such a way that we get negligible deflection during its working.

...more

portable spot welder

Car,LCV,HCV,Buses,scooter,Auto Rikshaw Load Bodies and their Components etc. The portable (suspended) spot welders are designed and manufactured to industrial standards and are available from 50 KVA and upto 250 KVA. Transformer 50% duty cycle 'F' class insulation confirms to IS 4804 (I) Guns 'X' or 'C' type water cooled pneumatically operated manufactured from cooper alloys for longer life. Controller Synchronous solid state four function each capable of independent timingamplitude setting plus stepless heat regulator The welder are supplied with kickless cable ,runway trolley and spring balancer

...more

multi spot welder

Lot of Automobile components , Engineering hardware, white goods require to be spot welded. Multi spot welding machine is a composite technology machine to achieve higher production. One of the methods employ common transformer and welding in sequence one after another spot welding. It helps restrict connected power load. Similarly a higher transformer capacity is installed and no. of spot welding takes place simultaneously to further boost the production. The cage welding machine is one of the application in enviro industry to manufacturer wire filters(cages) It consists of feeding the , straight wires into the wire holders, wire rings (predetermined quantity) are placed in the centre limb. Initiating the cycle makes pair of electrode come down and weld two joints at a time. In sequence all the joints are welded. The power source (transformer) of smaller capacity (usually 30 50 KVA) is installed. The auto function makes cage more out by predetermined pitch by pneumatic cylinder.

...more

metal gathering machine

Kejetherm Metal Gathering Machine is fully hydraulically operated with Resistance Heater. Principle of Operation Metal Gathering operation consists of heating the part of the job and pushing the remaining cold material of the job into hot zone till the required metal gathering takes place. Advantages By employing Metal gathering many of the well known technical limitations and disadvantages of mechnical upsetting can be overcomed. Simultaneous heating and forming in one machine. Almost unlimited gather in one operation. The mechanical upsetting limitation of about 3 x dia. no longer applies. The modern engine valve has an upset length of up to 20 x dia. and lengths of upto 40 x dia. are commonly electro-upset. No longitudinal flash is formed such as is unavoidable in a split-die mechanical upsettler. No waste of heating energy or material. Outside of the upset volume can be precisely controlled to allow subsequent, "flashless" forging in closed dies. Always ready for instant use, no warm up period. Energy efficient, about 0.35 - 0.40 kwh kg. Minimal scaling because of simultaneous heating and gathering. Improved die life in subsequent forging operations. No environmental pollution by emission of heat, fume or exhaust gas. Free upsets can be finished forged without re-heating and so save time and energy. Consistant heating temperature through the use of thyristor control. Optimal grainflow and fault free surface. The unheated bar length remains unchanged.

...more

Hot Sintering Press 3 phase

3 Phase Hot Sintering Machine With Vacuum For High Quality Production Of Diamond Tools Sintering Material Powder Technology Hydraulic Pressing And Heating For Sintering. Vacuum As Well As Inert Gases Are Used For Oxy Free Components At Very High Temperature.

...more

Hot Sintering Press

Rugged design and robust construction. the entire cycle is automatic except for loading the job. consistent product quality. least maintenance cost. precise temperature control. import substitute machine.

...more

Flash Butt Welder

Flash Butt Welding is a modern technique of joining mild steel, alloy steel and other dissimilar metals in various tubular or solid sections. Weld quality obtained is mechanically or metallurgically similar to the parent metal. Because of shorter weld times the process is suited for higher production than other conventional methods. No additional items such as rods or gas etc. are required thus it is highly economical. Other features include (a) little or no end preparation (b) High accuracy of welding joints (c) High consistency of weld parameters.

...more

Electric Resistance Heater

The Electric Resistance Heating is the least expensive way to change electricity into heat in any metallic object. In a furnace, the entire furnace has to be heated, the elements have to be heated, which in-turn many times heat a muffle which in turn heats the part in which heat is desired. Resistance heating is a more direct method of producing heat only in the object in which heat is needed. Just a few of the applications would be; wire drawing, extruding, warm or hot heading, brazing, forging, upsetting, roll parts, heat treating, heating strip stock for shearing, for forming, drawing and rolling, soldering and general purpose heating. TECHNICAL DATA

...more

Drill Rod Upsetting Machine

Consists Of Drill Rod Heating Either Electric Resistance Heater or Induction Heater. Special Purpose Hydraulic Press For Tip End And As Well As Shank End Forging. Brazing Of Carbide Tips.

...more

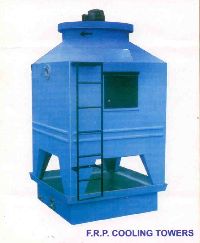

Cooling Tower

STANDARD RANGE : 22.5 KcalHr. TO 1 LAC KcalHr. APPLICATION :- REQUIRED FOR COOLING COPPER ELECTRODES , TRANSFORMERS SECONDARY,THYRISTORS STACK, HYDRAULIC OIL

...more

Copper Alloyed Seam Welding Wheels

Be first to Rate

Rate This