HIW-65 Hydraulic Ironworker Machine

Get Price Quote

Salient Features “Programmable logic controls” (PLC) is provided in our Machine of international standard make Delta, offering maximum production flexibility and full compatibility with international standards. Both cylinder are work independent (two worker can work as same time) Stroke adjust with the help of proximity sensor and light indication glass for easy stroke adjustment,MONOBLOCK Structure and Precise machining of the structural membrane is done to get the required accuracies like parallelism between platen and bed and right angularity. Between bed and the moving platen. ‘Auto Lubrication System: All moving parts are lubricated from a centralized lubrication arrangement with auto timer, once you fill lubricant no worry for 2-3 months about lubrication. Auto hold down mechanism which will give fast production rate and it hold material with heavy force and cut material so increase Die life with better cutting quality, Quick Die – Punch Mechanism:- you can change punch fast and easy, All die are inter-changeable so one die can use 2 to 4 times, also material and process of die so that it will give longer life without blending edge, Universal angle cutting mechanism will give possibility to cut wide range of angle size in one die, no die change required for bigger or smaller size of angle. The low noise hydraulic power pack unit is designed as per international practices and assembled with internationally reputed make components. The presses are designed as per ISI guidelines, hence standard seals, bushes are used. Machine have Guard at all station, electric switch and rubber pad which provide safety for operator and protect machine again dust and free-falling metal while cutting, All station of Shearing have common Stroke Counter, it will Count Number of Cut. Table Design with ‘T’ Slot, Regular die of Power Press can be Use on Ironworker Machine. Machine comes with all Standard accessories spanner set, warranty Card, instructional and maintenance manual. Machine Comes with Standard Functional Accessories: Die Set (total 14 Nos.): A 10 Pair of Punch and Die (select Any 10 Round Punch + Die Set from Dia. 8 Mm to 20mm) A Set of Angle Steel Cutting Blade. A Set of Square and Round Bar (or I Section or C Section) Cutting Blade (any One of Three) A Set of Flat-bar Shearing Blade. A Set of Notching Blade (v- Notch or Square Notch Any One) Die Set is Customizable as per Your Requirement, Please Freely Discuss with Our Company. Standard Functional Accessories: Automatic Multi Point 24v Dc Motor Operated Lubracting System 3 in 1 Die Holder (50, 73 Die Holder & Angle Punching) Hydraulic Hold-down Mechanism (auto Hold Angle & Flat) Back Gauge Mode (inching, Auto) Both Side E/stop Two Saparat Foot Switch

Dr-2 Hydro Dryer Machine

483,800 Per Piece

1 Unit (MOQ)

Best Deals from Textile Machine

Hank Dyeing Machine

Get Price Quote

We offer Textile Machine like Hank Dyeing Machine.

Fully Automatic Ginning Plant

Get Price Quote

Offering you with the finest automation solutions for Ginning Plants, we make available optimum quality Fully Automatic Ginning Plant. We are a reliable Manufacturer, Supplier and Exporter of Fully Automatic Ginning Plant in Gujarat (India). Our Ginning Plant is inclusive of Automatic Feeding Systems, Pre Cleaners, Over Flow Handling, Post Cleaners, Conveying Systems, Feed Regulators and PLC's to synchronize and control many processes. Minimum cost of production per unit and lower power consumption per quintal are the specialties of our Ginning Plant. Our Fully Automatic Plant is highly acknowledged in the market due to its attributes like high productivity, high quality output, less down time and efficient removal of dust and trash. We are committed to deliver the order within the stipulated timeframe.

Non Woven Fabrics Making Machine

Get Price Quote

Shell Removing Machine

Get Price Quote

Cotton Picker Machine

Get Price Quote

Semi Automatic Cotton Wick Making Machine

16,000 Per Piece

Bale Packing Ginning Automation Machine

Get Price Quote

Jewellery Ring Sizing Machine

Get Price Quote

1 Piece (MOQ)

JP Enterprises is a trusted jewellery ring sizing machine manufacturer. We offer ring sizing machines which are highly demanded by jewellers all over the globe due to their high level of accuracy and effectual performance. This wedding ring sizing machine is used to correct the size of the rings. This can be obtained at the most competitive prices in the industry and we are consequently regarded as the chief Jewellery Ring Sizing Machine Supplier in India. Infrastructure Our state-of-the-art infrastructure is equipped with the necessary machinery. Our infrastructure also includes quality control checks. Quality Assurance We conduct stringent quality tests for our quality assurance. These tests are conducted under the strict supervision of our quality control experts. At various stages of manufacturing of products, these tests are performed to eliminate the flaws in the end products. Our Team Our team is comprised of diligent workers who are an essential part of our enterprise. Besides this, our research and development unit looks after the advancements that are to be incorporated into the products to make them suitable for the diverse requisites of the customers. We deliver products all around the world and are counted among the best Jewellery Ring Sizing Machine exporters.

Ginning Machinery

Get Price Quote

Cottong ginning and pressing unit consisting single stage press Ganesh Engineering Kadi make, along with hydraulic unit, 54 inches double roll 10 nos. auto feeding gin machines including 8 nos. Jadhav make and 2 nos. of Bajaj make, pneumatic cyclone, elevators, conveyor and all necessary fixtures and accessories.

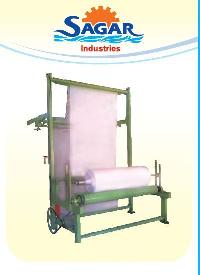

Textile Batching Machine

Get Price Quote

With features like superior quality and unmatched grade, our product range is the best one available in Rajkot(India). Want to obtain Textile Batching Machine at market's lowest prices? Deal with us. We are famous supplier of Textile Batching Machine. Our advanced Textile Batching Machine is designed for high strength, excellent corrosion resistance, easy use and low maintenance.

Bangle Sizing Machine

10,000 Per Piece

1 Piece(s) (MOQ)

We are offering bangle sizing machine. This new type of bangle sizing machine is very compact and useful to gold ,silver and imitation jewellery manufacture.

Cotton Roll Making Machine

50,000 Per Piece

1 Piece (MOQ)

Cotton Ear Buds Making Machine

Get Price Quote

1 Piece (MOQ)

Shree Hari 2 in 1 Round and Long Cotton Wicks Making Machine

25,000 Per Piece

1 Piece(s) (MOQ)

we are manufacturer and exporter of all kind of cotton wicks making machine and raw cotton for making cotton wicks. machine specifications: machine system: 2 round wicks and 1 long wicks cotton ring automatic feeding system fully noiseless advance technology machine dimension: 10x19x19 inch machine weight: 24-25 kg. production capacity: 15000-20000 wicks/day depend on woorker speed. multimedia technology inbuilt like fm radio, bluetooth, mobile connect, usb pen drive, auxilary port for listening musics and songs. digital voltage meter and digital counting system. user can adjust machine speed as per user require. machine price: 25,000 rs. + gst 18% + loading and packing 500 rs. = 30,000 rs. for more details and order kindly contact us.

60 Ton Iron Worker Machine

Get Price Quote

1 Set(s) (MOQ)

We are offering Iron Worker 60 Ton. Anasuya hydrauilc iron worker are designed & built to cut various material with different sections in easy & efficient manner, the machine is provided with different operation station in order to meet wide variety of cuttings; sections like angle, channel, flat & plate can be cut very accurately & precisely. moreover machine is also having one station where differing pressing operation like punching, blanking, piercing & bending can be done. specialization: punching. Flat shearing. Angle shearing. Bar shearing. Notching.

Flat Work Ironer

Get Price Quote

1 Piece(s) (MOQ)

The prachitirth flat work ironer is used to dry and iron all flat articles such as bed sheet, pillow covers, table cloth, napkins etc. Directly after the extraction process to produce a quality finish. The feeding and heating belts are completely imported quality. These belts do not absorb moisture and prevent the transfer of any marks to the articles being processed. Heat is transferred to the articles being processed via a heated cylinder manufactured out of complete boiler grade (for steam heated machines). The unique design of the cylinder enables the transfer of heat with a high pressure on the articles thereby creating a higher efficiency while can summing minimal energy. Heating of the cylinder is via steam or electricity. Very low power and steam consumption and a compact front feed, front return design ensure very minimal space consumption. A powerful blower ensures maximum removal of the moist air created within the machine. The electrical panel is equipped with a digital temperature indicator and digital speed indicator. A hand safety guard through the length of the cylinder and emergency stop buttons are provided to ensure a safe working. A variable speed drive for different types of fabrics and reversing of the cylinder are standard.

Air Jet Mill

Get Price Quote

Specification :- We are engaged in providing superior quality of Air Jet Mill which is developed according to the specifications of the consumer. We are one of the foremost service providers of the industry engaged in offering an Air Jet Mill to the customer, which is fabricated utilizing an optimum quality of raw element. Our whole provided array is accessible in various sizes, shapes and also be highly customized in different forms. These are utilized in the chemicals where sterility, ease of cleaning and also contamination free function are necessary. Here are some of the features of our Air jet mill such as simple maintenance, smooth operation and also heat resistant. Features :- Robustness, High durability, Accurate dimensions, Abrasion resisting, Easy to Operate Low Maintenance, Economical, Excellent Performance, Easy Installation Application :- Food & Spices, Pharma, Chemical, Minerals, Guar Gum, Starch, Pigment Colors, Dyestuffs - Fertilizer - Insecticides – Pesticides & etc.

Automatic Fiber Opening and Filling Machine

Get Price Quote

Multipro Automatic Fiber Opening And Filling Machine Having Two Station And Added Clamping System Is Latest Technology Machine Which Controls Filling Weight Automatically As Well As The Clamping System Holds Pillow/Cushion Cover During Filling Which Is Like Hands Free Operation. The System Is Time Based Auto Stop System Hence Completely Unskilled Operator Can Fill The Pillows/Cushions Fast And Chances Of Weight Errors Are Rare. The Machine Is Attached With PLC Based Control System And Easy To Operate. Key Features: Improved Safety - The Machine Having Improved Safety Features Like Overload Protection, Phase Sequence, Overload Buzzer, Roller Movement Indicators, Stoppage of Machine When Lid Opens and Many More Automatic Filling Weight Management - Time Based PLC Loaded Automatic Synchronization Of Clamping System With Fiber Filling Unit Shutter Operation Which Manages Weight Hands Free Filling System - The Machine Is Having Added Clamping System Which Holds Pillow/Cushion Covers During Filling and Operation is Hands Free. High Production Rate - Provided Double Filling Stations and > 200 kg/hr Opening Capacity As Well As Auto Stop System Increases Production Rate. Long Life Metal Clothing - Provided New Generation V Grooved Metal Clothing Which Are Long Life Than Conventional Clothing Smooth Operation - Dynamically Balanced Rotors Are Fitted Which Are Having Smooth Operation Of Machine During High Speed Working. Compatible With Wide Range Of PSF - Need Single Machine For All PSF Like 6D, 7D,15D, Hollow/Conjugated/Siliconized Having Cut Lengths Of 32,44,51,64mm. Technical Specifications: Fiber Opening Capacity - 200 ~ 250 kg/Hour Fiber Filling Capacity - 500 ~ 700 Pillows/Cushions Per Hour ( Depends Upon Size/Filling Weight ) Suitable Raw Material - Polyester Stapled Fibers Above 6D Electrical Specifications: Power - 9.25 kW (Opening Machine 6.25 kW + Filling Machines 3 kW) Voltage - 380 V / 50 Hz ( Can Be Customized According To Country-Wise Compatibility ) Product Size & Weight: Opening Unit(L*W*H) - 1324 x 1963 x 920 mm Blower Unit(L*W*H) - 600 x 560 x 960 mm X 2pc Connector Pipe - 800 mm X 2pc Weight - 890 kg Packing Detail: Packing Method - Stretch cum EPE Foam wrapped machine in Wooden Case Opener Packing Dimensions(L*W*H) - 1400 x 2040 x 995 mm Weight - 1060 kg Installation, Training & After Sales Service: Provided by our engineers Replacement Spare Parts - Available to supply against defective part/item On Site Service - Available in 7 days upon request E-mail, Phone, Support - 10am to 5pm Mon-Sat