Multistage Cleaning System

400,000 / Unit

Aqueous Cleaning Systems

Get Price Quote

Centralized Vacuum Cleaning Systems

Get Price Quote

Fin Cleaning System

Get Price Quote

Web Cleaning System

Get Price Quote

Tube Cleaning

Get Price Quote

Self Cleaning Filter Systems

1,500,000 / Piece

SERIES-SABRINA

Get Price Quote

MODEL TCS-40 Chiller Tube Cleaning System

Get Price Quote

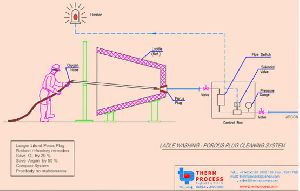

Porous Plug Cleaning System

Get Price Quote

Tube Cleaning Systems

Get Price Quote

Gas Cleaning System

Get Price Quote

Spices Cleaning System

Get Price Quote

High Pressure Cleaning System

Get Price Quote