Wind Solar Hybrid Power System

Avail from us, the efficient Wind Solar Hybrid Power System, which is highly demanded by the widespread clients. Being one of the leading Manufacturers, Exporters and Suppliers in India, we provide Wind and Solar Hybrid Power System at the most competitive prices. Description Plant available form 5 KW to 100 KWSmall vertical wind turbines suitable for urban areasVery low cut in wind speeds (2 m/Sec)Turnkey solutions on EPC basisSuitable for Domestic and commercial applications

Type : Renewable Energy System

...more

Waste Heat Recovery Systems

Our products are widely praised owing to their premium quality and perfection, thus checked against diverse quality parameters. The organization is a trusted name based in Visakhapatnam(India) and known for its fair pricing policy.

Type : Industrial Equipment

Material : Steel

Color : Multicolor

Packaging : Standard Industrial Packaging

Application : Recovering Waste Heat In Industrial Processes

...more

Waste Heat Recovery Power Plant

We are offering Waste Heat Recovery Power Plant. First ESCO India Pvt. Ltd. was incepted in the year 2008 in Andhra Pradesh. The company is being efficiently managed by the experienced Managing Director, Dr. Vijayakumar Kunche. In a short time span, the company has set a benchmark for itself in the worldwide industry. The company is known for supply of ORC WHR power plants to Cement Plants, Glass Factories, and Steel Industry etc.

...more

Vapor Recovery Systems

We are deeply ingrained in Visakhapatnam(India) and carved a niche for ourselves by offering the finest products at very affordable rates. Our packaging professionals ensure that the products enclosed in the package are protected from vibration, shock, compression, temperature and various other external factors.

Type : Vapor Recovery Systems

Packaging : Protected From External Factors

...more

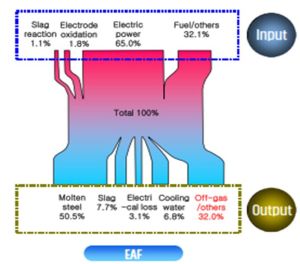

Steel Industry

Steel industry is energy intensive, requiring large amount of electrical energy as well as heat energy through use of fossil fuels. In most of the furnaces used in the steel making process, some amount of heat energy will be lost to the atmosphere through flue gases. Typically, 20-25% of the input energy is lost through exhaust flue gas. It is common in many of the steel manufacturing facilities to recover the heat that is lost to the atmosphere and use it for process heating or power generation.However in many plants, the heat energy lost through flue gase from electric arc furnaces(EAF) is not recovered. Typically, the eaxhaust as from an electric arc furnace will be at 900°C and the thermal energy lost to the atmosphere would be 8000KWth for a 50 ton electric arc furnace. By installing our ORC power system, it is possible to recover upto 2MW of electrical energy using this heat with a 50% duty cycle.

...more

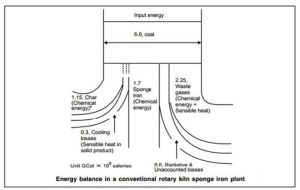

Sponge Iron

Sponge iron kilns are energy intensive. 30% of the energy input to the kiln is lost to the atmosphere through flue gas. Many sponge iron plants with kiln capacity higher than 200 tons, the heat in the exhaust flue gas is already utilised to generate steam and generate power. However, sponge iron plants with a capacity less than 200 tons normally let out the flue gas into the atmosphere after cooling the same in forced draft cooler(FDC). Hence there is a great oppurtunity for these plants to install ORC power systems for conversion of waste-heat to power.As per conservative estimates, it is possible to generate upto 1.5MW electrical power from the waste flue gas emnating from a 200 ton sponge iron kiln.

...more

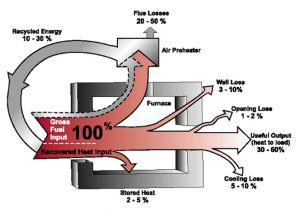

Glass Industry

Glass kilns utilise heavy fuel oil (HFO) or natural gas. Typically a glass furnace exhaust flue gas will be at a temperature of 450-500°C. As per available statistics, the energy lost through exhaust flue gas will be in the range of 25-30% of input energy. For a seven hundred ton capacity glass furnace, the energy lost to the atmosphere through flue gaswill be typically 8000KWth. FirstESCO supplies technology for recovering this heat energy lost to the atmosphere and converting into useful power using ORC power systems. Typically for a 700 ton glass furnace, it is possible to generate upto 2.5MW using ORC power system.

...more

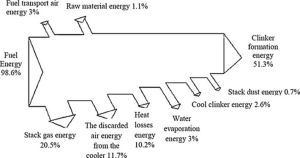

Cement Industry

Cement manufacturing is an energy intensive process. By improving the energy efficiency in terms of thermal and electric energy, it is possible to improve the bottomline by cost optimisation. In a cement kiln, 22.5% energy input is lost to the atmosphere through flue gases. By recovering the thermal energy available in the pre-heater flue gas as well as in clinker-cooler exhaust, it is possible to generate enough electrical energy to meet 30% of power requirement.FirstESCO offers innovative heat recovery and energy conversion by using organic rankine cycle(ORC) power systems

...more

Biomass Gasification Power Geenration

(a) Bio mass is first convereted in to SynGas in a Bio Mass Gasifier and then after cleaning, same will be used in a SynGas Engine generator to generate power. Simple to use. Very fast installation, High effciency, suitable for Co generation ( we can use the waste ehat from the Engine exhaust for generating steam / hot water) (b) Bio mass gasification power generators are available in various sizes form 5 KW to 5000 KW and in multiples of the same. (c) Very low fule consumption (d) Suitabel for operation with wood chips, wood pellets, Rice husk, mustard husk, wheat husk, cotton stalk, farm waste, municipal sold waste RDF pellets (e) Very low generation cost per unit (f) Quick pay back ( less than 4 years)

Type : Biomass Gasification Power Generator

Material : Metal, Plastic, Etc

Feature : Simple To Use, Fast Installation, High Efficiency, Suitable For Co-generation, Low Fuel Consumption, Low Generation Cost, Quick Payback

...more

Automated Street Light Controllers

Quality being the major concern of our organization, we keep a stringent check on the production, packaging and delivery processes. Engaged in the industry as a prominent Supplier of automated street light controllers, we present the finest range of products.

Type : Electronic

Feature : Automated Control Of Street Lights

Application : Controlling Street Lights Automatically

...more

ORC Waste Heat Recovery Plants

Nox Reduction Systems

Sox Reduction System

Petcoke Firing Systems

Petcoke Firing Petcoke is an alternative Fuel It is a residue from Petroleum Refining It has High Fixed carbon (> 90%) High calorific value : 8400 kcal/kg Low cost Fuel Easy to handle Possible to replace HFO / LPG/ PROPANE/ NG Why Petcoke Low cost compared with HFO / LPG/ NG) Reduce Operating cost) Improve profitability) Easy to Do fuel switching) Very quick Payback period ( 3 to 4 Months)) Can be implemented in 16 weeks period) Systems will meet environmental regulations).

...moreOpening Hours