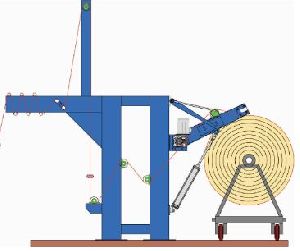

Pneumatic Big Batching Machine

Get Price Quote

1 Piece (MOQ)

Can wind the Fabric edge to edge, creaseless at speed upto 90 Meters/ Minute. Provision of Pneumatic Cloth Guider help in edge to edge einding of the fabric without any damage upto 1500 mm Diameter. Universal machine for woven and non-woven Fabric. Less space required. Working Width ranges from 1400 mm to 3400 mm. Batch created on this machine are most useful to be installed before entry in Flat Printing Machine or Rotary Printing Machine.

Stationary Concrete Batching Plant

890,000 - 9,800,000 Per piece

1 Piece (MOQ)

Best Deals from Batching Plants

Inkjet Batch Coding Machine

11,000 Per piece

Fully Automatic Batch Coding Machine

Get Price Quote

10 Piece (MOQ)

Double Drum Asphalt Mixing Plant

3,500,000 Per Set

1 Set(s) (MOQ)

Our double drum hot mix plant is suitable for high capacity mixing requirements, in out double drum asphalt mixing plant the drying of aggregates and mixing of aggregates is done in two different drums given precise mixing quality with anti gradation of aggregates and mix recipe.

Concrete Batching Plant

1,500,000 Per Set

1 unit (MOQ)

Concrete Batching Machine

Get Price Quote

We are offering concrete batching machine. specifications: batch capacity:2 hoppers of 1 bag capacity each-to-sand & receive metal. chassis:heavy duty robust made out to heavy section. transmission:by mechanical joints provided with dust covered bearings. lever type system :pan weight of 50 & 100 kg and jockey weight to adjust the weight from 0 kg to 50 kg's. handling :m. S. Fabricated wheels

Mobile Concrete Batching Plant

Get Price Quote

Our company is renowned as one amidst the forefront Concrete Batching Plant Suppliers in India. Catering to the exact expectations of the national as well as international clients, the company has acquired noteworthy position amidst the reliable Mobile Concrete Mixing Plant Exporters. The Mobile Concrete Batching Plant is ideally designed to be used in different building sites and for the production of base for roads, bridges, dams, aerodromes etc. Moreover, some of the salient features of the Concrete Batching Plant are as mentioned below: Salient Features A single chassis model mobile batching mixing plant.Completely mobility, free transportation.Re calibration is not required in change of installation plant.Accurate electronic weighing system is reliable & fast .In facility online printer system.Loading of aggregate & sand hopper by tractor mounted feeding LOADER/JCB.Separate weighting system aggregate / cement / water & additive is dosing in system fast & accuracy high Plant only requires electric power supply, water connection aggregated, sand feeding.Promote after sales & services & spares backup.Free technical guide & online support.Easy disassembling and pre-assembling.Low cost and high efficiency.Low investment,low maintenance.

Asphalt Drum Mixing Plant

Get Price Quote

Our heavy-duty construction machinery comprises Asphalt Drum Mix Plant that is specifically designed to serve varied demands of road construction. These plants give optimum performance at low maintenance cost. Further, these are offering in different models and also in customized forms.

Heavy Duty Batching Motion Machine

Get Price Quote

Fabric rolling for all types of automatic looms type of Sulzer, Piconol, Omni, Toyoth, Tsudakama, etc. Features: Fabric rolling for all types of automatic looms type of Sulzer, Piconol, Omni, Toyoth, Tsudakama, etc. Denim, Low Bottom Weight, Ind. Fabric, Technical Fabric, Non Woven fabric rolling Custom built version for larger working width 1150 to 4000mm Synchronize for fabric even tension rolling.

Batch Coding Machine

1 - 1,111,110 Per Container

buy batch coding machines in ahmedabad. acuapuro water is ahmedabad's leading manufacturer & supplier of automatic batch coding machine, inject coding machines, manual coding machine.

Static Inline Hopper Concrete Batching Plant with Twin Shaft Mixer (GEPL SIH - 60)

Get Price Quote

With a GEPL SIH 60 model, our Static Inline Hopper Concrete Batching Plant with Twin Shaft Mixer is bigger and more powerful than ever. Easy to maintain, and made with high quality premium grade raw materials that are sourced from India’s leading raw materials supplier, our Static Inline Hopper Concrete Batching Plant with Twin Shaft Mixer (GEPL SIH - 60) is also guaranteed to have a long service life, maximizing efficiency in the factory for all.

Concrete Batching Plant

800,000 - 2,500,000 Per Nos

10 piece (MOQ)

Concrete Batch Plant

Get Price Quote

A concrete plant, also referred to as batch plant, batching plant, or a concrete batching plant, is equipment which mixes different ingredients or materials to make concrete. The inputs utilized might be water, air, admixtures, sand, fly ash, silica fume, slag, and cement. Four Bin System Load out Conveyors Pan Type Mixing Unit

Semi Automatic Batch Coding Machine

Get Price Quote

Purchasers can rely on us to make on time distribution of orders, as we have cooperated with established transportation facility providers. Your search for exceptional quality and reliable Semi Automatic Batch Coding Machine; we are a leading Supplier in this domain. Features : We are semi coding machinery manufacturers. Suitable for printing on the label, pouches, jars, bottles, cans, tubes, cups, cartons and any even surface. Suitable for all manual & automatic coding on various packing. Compact design makes it easy to install where space is limited. Motorized intermittent reciprocal contact coder so no requirement of Air supply. It can also be installed in various positions according to the design of the parental machine. It runs by footswitch, proximity switch & inbuilt timer operation. Uses quick drying liquid ink , dry within minutes to support fast production. Specifications : Printing Size - 35x35 mm or 35x50mm( other sizes can be manufactured on demand) Printing Speed - 40 to 60 prints/minute or depending on machine set-up conditions. Higher speeds are available as well. Printing Method - Ink transfer by flexo types Grooved / Flat stereos- 3 mm size or other required size. Grooved stereos are an interlocking type. Printing Media - Anti- Freeze fast drying’ liquid Ink. Inking System - Inking cartridge made from specially imported material to release the right amount of Ink per each impression. Power Supply - 230 VAC ± 10 %, 50 HZ, Single phase. Ink Charge - 5-10 ml, ink per charges, gives 10,000 to 20,000 impressions depending on size of marking

Semi Automatic Batch Printing Machine

Get Price Quote

Automatic feeding by slant magazine allows labels to a polished stainless steel feed wheel, The Label is picked up by rubber and it is fed to a timing chain, which carries the label under the printing head. Very useful machines to all Pharmaceutical & other packaging industries to print Batch No.., Mfg. Date., Exp. Date., Retail Price etc. on their Labels, Cartons, Polypack Bags, Pouches, tin Bottoms, Cotton Bags etc. Hand Operated and Semi Automatic Batch PrintingCoding Machines are working on the same principal of tradle machine conventionally used by all the printers. In both the machines the matter is to be composed in type block with type letters. Ink to be fed on the Aluminium Roller. On each stroke of the machine the composed type letters are linked by moving Rubber Roller. LabelCartonBag fed on plate is getting positive impression by inked type letters. Semi Automatic Batch PrintingCoding Machine is Electrically Operated and foot Switch is provided to 'ON' or 'OFF' the machines as both the hands of the operator remain free in convenience of feeding and discharging the LabelsCartonsBags. While in Hand Operated Batch PrintingCoding Machine in addition of feeding anddischarging the LabelsCartonsBags by hand, the stroke of the machine is also operated by hand.

Batching Motion

Get Price Quote

Batching Motion, Fabrics Cutting Machine, Zig Zag Cloth Cutting Machine

Inkjet Batch Coding Machine

45,000 - 60,000 Per PCS

Batching Motion

Get Price Quote

1 Set(s) (MOQ)

The "Batcher" is an winding Application, Which can be installed on any type of textile looms .it is attach with Heavy duty M.S Plateform and side bracket plates with S.S Gide Roll for Better handling of production And Accurate winding On the Fabric Roll, It Comes With Best Quality Of Gear Box Which Ensures Uniform Wind Of Creas-less Fabric. Our New Design Injector For Big Fabric Roll Doffing On Batching Motion TO Trolly By Easy Manual System. Direct Attach On Batching Motion Machine.