+3

+3

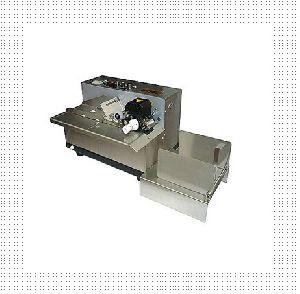

Mechanical Affs Machine With Batch Coding

135,000 - 165,000 / piece

Used Batching Plant

2,000,000 / Set

Label Feeder Coder

50,000 / Piece

Table Top Batch Coding Machine

Get Price Quote

Automatic Batch Coding Machine

Get Price Quote

Batch Plant

Get Price Quote

Four Bin Concrete Batching Plant

Get Price Quote

Batch Code Printing Machine

Get Price Quote

Batch To Roll Axial Fabric Inspection Machine

Get Price Quote

+1

+1

Manual Batch Printing Machine

2,599 - 3,499 / Piece

Automatic Batch Coding Machine

Get Price Quote

Motorized Batch Printing Machines

Get Price Quote

POP Batching Plant

Get Price Quote

Batch Coding Machine

8,000 / Piece

Concrete Batch Plant

1,500,000 / Unit

Table Top Batch Coding Machine

28,000 / Piece

Candy & Toffee Batch Roller

Get Price Quote

Inkjet Batch Code Printing Machine

26,500 / Piece

Concrete Batching Mixing Plant

Get Price Quote

+5

+5

Batch off Cooling Machine

1,500,000 - 4,000,000 / piece

Automatic Batch Printing Machine

Get Price Quote

Batch Coding Machine

8,000 / Units

Batching Plant

Get Price Quote

Twin Shaft Batching Plant

Get Price Quote

Ordito Big Batching Machine (Oi -102)

Get Price Quote

Batch Coding Machine

Get Price Quote

Twin Shaft Batching Plant

Get Price Quote

Hsco Wet Mix Batching Plant Hscowmp

Get Price Quote

Mini Batching Machine

Get Price Quote

Inkjet Batch Coding Machine

Get Price Quote