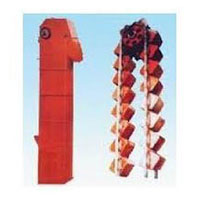

Bucket Elevator

280,000 / piece

Bucket Elevator

Get Price Quote

Bucket Elevator

8,000 - 125,000 / Feet

CNC BUCKET ELEVATOR

3,000 / Feet

+2

+2

Bucket Elevator

Get Price Quote

Stainless Steel Bucket Elevator

60,000 / Piece

Chain Bucket Elevator

Get Price Quote

Weigh Filler Machine

40,000 / No

Bucket Elevator

10,000 - 250,000 / piece

+1

+1

Bucket Elevator

27,000 - 100,000 / piece

Bucket Elevator

200,000 - 5,000,000 / Piece

Bucket Elevator

Get Price Quote

Bucket Elevator

100,000 - 145,000 / piece

+4

+4

bucket elevator conveyor system

175,000 / Piece

Bucket Elevator

Get Price Quote

Centrifugal Discharge Bucket Elevators

Get Price Quote

Bucket Elevator

Get Price Quote

Stainless Steel Bucket Elevator

100,000 - 500,000 / piece

Bucket Elevator

Get Price Quote

+2

+2

Industrial Bucket Elevator

150,000 - 500,000 / Piece

Inclined Bucket Elevator

350,000 / piece

Bucket Elevator

8,500 / Feet

Bucket Elevator

8,000 - 125,000 / Feet

Bucket Elevator System

300,000 / Unit

+6

+6

Bucket Elevator

8,000 - 126,000 / Feet

+2

+2

Bucket Elevator

8,000 - 125,000 / Feet

Bucket Elevator

90,000 - 100,000 / piece

Bucket Elevator

Get Price Quote

Chain Bucket Elevator

65,000 - 250,000 / Set