feedwater heaters

Get Price Quote

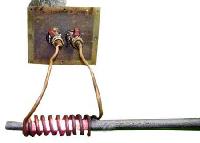

The needs of the power generation industry include year-in and year-out reliability, optimum performance for maximum efficiency, and absolute on-time delivery to meet plant outage schedules.All of the Jet Flow Feed Water Boiler Heaters are designed in accordance with HEI standards, TEMA and ASME codes. Jet Flow uses state-of-the art computer programs to perform the thermalhydraulic and mechanical design of each Feed Water Heater we fabricate.Jet Flow designs and manufactures both Low Pressure (LP) and High Pressure (HP) feed water heaters which may be installed either vertically or horizontally, depending on the plant design requirements.Each Jet Flow LP / HP Feed Water Heater will contain from one to three separate heat transfer areas of zones including the Condensing, De-superheating and Sub-cooling zones. Our heaters can be provided with multiple zones within the shell side: Condensing Zone : Included in all heaters,steam is condensedin this zone and non-condensable gases are removed. Drain Cooling Zone : Reduces temperature of drains leaving the condensing zone to below the saturation temperature. Jet Flow is able to provide both fullflow and partial flow drain cooling zones to meet specific plant requirements. DC zones can be applied in any horizontal or verticle heater as needed to meet plant requirements. Desuperheater Zone : Floating design and shielding at the tubesheet minimise thermal stresses. All operating cases are analysed to ensure wet wall conditions are prevented. DSH zones can be applied any horizontal or verticle heater as needed to meet plant requirements. Jet Flow’s engineers are always available to assist you in determining those design parameters and how they will impact performance in your power plant. Jet Flow understand the unique needs of the power generation industry and provides it feed water heaters that withstand years of rigorous service. Jet Flow Feed Water Heaters are designed for specific thermal conditions and manufactured for a singular purpose. Whether it be sophisticated designs involving extreme superheat, abnormal flow conditions or dissipation of high energy fluids.In addition, Jet Flow provides innovative and practical concepts to ensure peak heater performance from installation to testing through full or part load operation. We offer a multitude of design configuration for de-super heater and drain cooler zones as well as the latest channel closure techniques.All shell & tube heat exchangers, irrespective of the type of service for which they were designed, must withstand severe service conditions. The service life of feed water heaters, however, is one of the toughest because of the longevity and reliability factors inherent in power plant equipment designs. Jet Flow thorough understanding of these factors enhances its ability to communicate clearly with power design engineers. Jet Flow designs enable power engineers to anticipate maximum efficiency from the turbine extraction steam in preheating the boiler feed water.Scope offering: Jet Flow low pressure boiler feed water heaters can be provided in any orientation and contain multiple shell side zones as required to meet the need of the specific plant application. Standard tube material for Jet Flow Feed water heaters is corrosion and erosion resistant austenitic stainless steel. Tubes are expanded in the tubesheet as a standard, but can be welded when required. Jet Flow boiler feedwater heaters are manufactured according to the strict quality standards. Testing and certification by the responsible authorities including IBR are performed in the production facility. Along with the heaters, Safety Relief Valves, Thermal Relief Valve, Level Instruments and Gauges can be supplied.

HP Feedwater Heater

Get Price Quote

The H.P Feedwater Heater can enhance the efficiency of the power plants while minimizing the heat effect at the same4 time. The structure of the H.P Feedwater Heater is based on tube heat exchange and the durability and safety levels are high. The company has emerged as a prominent Manufacturer and Supplier of H.P Feedwater Heater.

Best Deals from Feedwater Heaters

feedwater heaters

Get Price Quote

We are offering feedwater heaters. Chem process systems offers high quality feed water heaters to meet the client’s requirements in the power generation, chemical, petrochemical and marine engineering industries. We design and manufacture both low pressure and high pressure feed water heaters which may be installed either vertically or horizontally, depending on the plant design requirements. Conservatively designed tube bundles and proven venting concepts provide permanent protection against damage and guarantee optimal heat transfer. We offer the complete range of feed water heaters for nuclear and large scale conventional power plants, such as: u-type feedwater heaters duplex heaters with u-tube bundles heaters with drain cooling and steam desuperheating sections

HP Feedwater Heater

Get Price Quote

The H.P Feedwater Heater can enhance the efficiency of the power plants while minimizing the heat effect at the same4 time. The structure of the H.P Feedwater Heater is based on tube heat exchange and the durability and safety levels are high. The company has emerged as a prominent Manufacturer and Supplier of H.P Feedwater Heater.

feedwater heater

Get Price Quote

Feedwater Heater systems can extract up to 30% of the turbine throttle steam. The use of this energy source is critical for efficient generation of electric power. Each feedwater heater is designed to specific thermal conditions and manufactured for a singular purpose. We have the expertise and experience to offer proven solutions to any design problem.

feedwater heater

700,000 Per Piece

feedwater heaters

Get Price Quote

TEMA India is engaged in the design, engineering and manufacture of Shell & Tube Heat Exchangers. Beginning in 1984 with a revenue of $100,000, the company has grown to be one of the largest manufacturers of Shell & Tube Heat Exchangers in India with three manufacturing bases close to its headquarters in Mumbai. Export orders contribute to nearly half the turnover.TEMA specializes in critical equipment such as Screw Plug (Breech Lock) Exchangers, Helical Baffle Exchangers, Rod Baffle Exchangers, Feedwater Heaters, Surface Condensers and Waste Heat Boilers.With each passing year the company has moved up the value chain, in terms of both, metallurgy and criticality of exchangers. It caters to industries in the Oil, Gas, Petrochemicals, Specialty Chemicals, Fertilizer, Nuclear and Power sectors.

feedwater heaters

Get Price Quote

feedwater heaters, Condensers, drain cooler, fresh water cooler

feedwater heater

Get Price Quote

feedwater heater, superheaters

feedwater heaters

Get Price Quote

feedwater heaters, hot insulation services, building insulation services