Speed-O-Control Thrusters

Get Price Quote

10 Piece (MOQ)

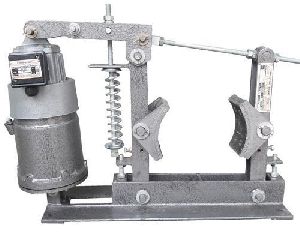

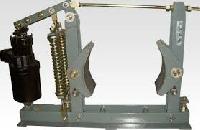

Owing to our reputation in the industry for optimum quality, we are involved in offering a wide range of Speed-O-Control Thrusters to our valuable clients. The offered thrusters are widely used to actuate thruster shoe brakes, commonly used in material handling equipments. The offered thruster is made of high grade raw material. We are offering these in a wide range of thrusters to fulfill the various needs of our valued customers. Features: ♠ Optimum Performance♠ Fine Finish♠ Robust Construction

MDT 150-18 Mill Duty Thruster Brakes

11,300 Per Piece

5 Piece (MOQ)

Best Deals from Thrustor Brake

stern thruster

Get Price Quote

100 Piece (MOQ)

Thruster Brake

Get Price Quote

50 Piece (MOQ)

Thruster Brakes

13,000 - 90,000 Per pieces

10 Piece (MOQ)

Plicare Material Handling PVT LTD takes immense pride in being a leading Thruster Brakes exporter, offering high-quality braking solutions for a wide range of industrial applications. Our thruster brakes are designed to provide reliable and efficient braking performance, ensuring safety and control in critical operations. Our thruster brakes undergo rigorous testing and quality checks to ensure optimal performance, durability, and compliance with international regulations. We offer a comprehensive range of thruster brakes with varying capacities to cater to different load requirements. With our Thruster Brakes, you can enhance the safety and efficiency of your operations, minimize downtime, and protect your valuable assets. Contact us today to explore our range of high-quality thruster brakes and experience the reliability and excellence that sets us apart as a leading exporter in the industry.

hydraulic thruster brake

7,000 - 40,000 Per Piece

Thruster Brake

Get Price Quote

100 Piece (MOQ)

Electro Hydraulic Thruster Brake

Get Price Quote

Electro Hydraulic Thruster

3,500 - 18,000 Per Set

1 Set (MOQ)

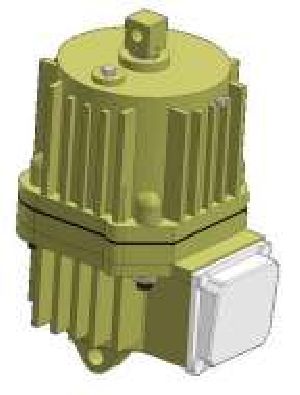

Thruster is an electro hydraulic device, designed to exert acontast force to any mechanism to be operated. The Thruster work on a principle of hydraulics. On supply of eectric power, motor driven centrifugal impeller draws the oil from the low pressure end of the chember to the high oressure upper end. The piston mounted on the same shaft moves to the upper end with full thrust, till its movement is stopped by the stopper shoulder at the end of the stroke. Pressure build up stops when power is discontinued. Radialblade design of the impeller enables it to rotate both in clockwise and anticlockwise direction. Therefore power supply to star connection can be in any R-Y-B phase sequence.Special Features : Packaged self contained unit-No external piping and accessories required. Self aligned movement Rated force available for the entire stroke Compatible for use with any exiting or new system. Low power consumption Moving parts being immersed in oil, No frictional losses. Minimum maintenance. Thruster Set 520 :A compact 90 watt, 415 volts, 50 cycles, 3 phase Electric motor is directly mounted on the top of a piston. The piston is housed in the C.I. Tank filled with fluid. The piston moves the fluid from low pressure are to high pressure area. The specially designed impeller which is mounted on the motor shaft produces required fluid pressure.Thruster : ST 535 tost 13300 This range of two thrust rods and a common piston. The motor is mounted on the top cover of the tank. A separator plate divides the tank in two partitions-low pressure side and high pressure side. The spacer bushes control the thruster. The models are suitable for large capacity, Higher motor ratings and larger thruster forces.Maintenance :The thruster is designed for long trouble free service and needs no maintenance. The motor bearings are adequately sized and windings are designed to meet the sudden jerks and shocks. Normal maintenance like topping of the oil levels replacement of damaged worn out oil seal and gaskets is required. The terminal box must be cleaned periodically.

Hydraulic Thrusters

Get Price Quote

Electro Hydraulic Thrusters are the hugely acknowledged product of our offered range. We are pleased with the response, which clients have shown in our supplied Electro Hydraulic Thrusters. Provided with high-capacity drum, these Electro Hydraulic Thrusters are catered through us in worldwide markets.

HYDRAULIC THRUSTER DISC BRAKES

Get Price Quote

Hydraulic Thruster Brakes: Our products are used extensively in the Mining, Ports, Steel and Power Generation industries on Conveyor drives, Stackers, Reclaimers, Ship Loaders, Ship-to-Shore, overhead and Gantry Cranes to name a few�

Electro hydraulic thrustor Disc Brake

Get Price Quote

Thrustor Brake

Get Price Quote

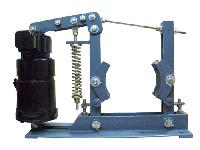

OperationThe braking torque is applied through the action of compression springs that operate the shoes when the current is interrupted. When the current is switched on the shoes is lifted from the drum, the electro-hydraulic thrustor unit acting against the pressure of the springs. The normal position of the brakes is, therefore, 'ON' (shoes gripping the drum), and the brake will return to this position when the current fails. General SpecificationBreak ConstructionThe brakes are robustly made with few and simple working parts, The shoes and base of close grained cast iron and the fulcrum pins are of ground mild steel working in long, reamed bearings. The shoes are fitted with easily renewable woven, fibre, linings held by countersunk rivets, They are adjustable for wear and the pressure exerted by them is easily varid Pivoted shoes are standard on all thrustor-operated brakes. ThrustorsThese are standard electro-hydraulic supplied complete with their first filling of oil. This is 'insulating' oil, Grade 8.30 to British Standard 148, which is readily available at home and overseas. The thrustor cannot be injured by overload or under load. WindingsAll size can be wounded for 3 phase A.C. supplies up to 550 volts and outputs are given here for 50 and 60 C/S supplies. For lower supply frequencies the outputs will be reduced and enquiries should-be referred to us. All thrustors are continuously rated. EnclosuresAll standard units are totally enclosed. Dust seals are fitted as standard, but in extremely dusty situations, or for mounting in the open, a cowl or cover the thrustor is recommended. Cable EntryStandard units have tapped ¾ inch BS conduit thread. Supply leads must be flexible to allow free movement, and cables should have 18 inches free length and be not larger than three-core 7/0.029'' to avoid side drag. Optional Special FeaturesManual ReleaseA level for releasing the brake can be fitted at a small extra cost; this lever is self-resetting. Hydraulic Over-RideHydraulic control, which enables the brake to be applied by the operator by means of a lever or pedal while the thrustor is energized, can be fitted at extra cost. These brakes can be supplied complete with master and brake cylinder, copper pipe and pedal assembly. Brake DrumsBrake drums, or drums combined with rigid or flexible couplings, can be supplied to customers' requirements at extra cost. A stout high duty cast-iron drum will be supplied with the brake, if specified. Drums are machined and keywayed ready for fitting to the motor shaft at cost. Asbestos LiningsAsbestos linings can be fitted to any of the brakes listed in the table. These linings withstand higher temperatures but result in reduced torques, about 0%, because of their lower friction coefficient. They should only used when drum temperatures of over 2200F have to be tolerated and should be the subject of a special enquiry to us. Choosing The Correct BrakeWhen selecting a brake from the rating table, opposite, it is important to consider not only the brake torque but also its duty, i.e. its frequency of application and the duration of each stop. Torque When a large amount of store energy has to be dissipated or when the stopping times is specified, it will be necessary to caculate the torque from inertias and speeds of the moving parts. For many purposes, however the braking torque can be related to the torque being transmitted. The full load torque of a shaft transmitting a known horsepower is given by:Torque (lb-ft.) = hp x 5250 rev/min of shaft.Usually, sufficient will be known about the drive to enable a suitable brake torque to be determined. DutyThe bake must be chosen with consideration of its intended duty to ensure that the linings will not overheat or wear down too quickly. Selection of a brake for torque only would not ensure this. Since the speed of the drum will also affect the rate at which the drum can dissipate the absorbed energy without overheating. The higher the drum speed for a given torque, the higher will be the rate of energy dissipation in the brake linings during each stopping period the rate being expressible as a horsepower. The column headed 'Nominal horsepower based on linings' in the table is intended as a rough guide to the horsepower of the motor for which a brake is suitable when the duty is equivalent to 'normal' crane duty, i.e. not more than 120 operations per hour continuously applied and with a stopping time not exceeding about one second. If the duty of the brake is less than this 'normal' the horsepower given in the table can be increased. If however, the frequency of application is greater or the stopping time is longer, a larger brake may have to be used; asbestos linings can be fitted and a higher drum temperature accepted with a lower torque. Details of brakes with non-standard features may be obtained from us."EMC" THRUSTOR OPERATED BRAKESAC THRUSTOR-OPERATED BRAKES have a wide application; they can be used with such machinery as electrically driven hoists, cranes elevators, ropeways, machine tools, mixers and laundry machinery.

Eldro Thruster Brake Series Mill Duty MDT

Get Price Quote

Features Robust and rugged design to withstand arduous environment in Steel, Rolling Mills, Elevators, Lifts, Cement and other heavy engineering plants. Excellent design and good manufacturing processes ensure a reliable product. Consistent braking torque due to selected and tested brake lining material. The design ensures efficient distribution of forces. Sturdy components and Thruster ensure long, trouble free service and requires no major attention. Ease of maintenance and replacement of brake shoes without dismounting the brake. Compost designs and elegant aesthetic looks. ApplicationsSteel Plant, Material, Handling Cranes, & Conveyors.

Hydraulic Thrusters

Get Price Quote

We are offering hydraulic thrusters. Thruster only: thruster brake is a device used to retard the speed of moving machinery and to stop it accurately to the desired position. The braking force is applied to the brake shoes by a pre-stressed comprising spring. The shoes press on the rotating brake drum retarding its speed and finally stop it. The releasing of the.

Electro Hydraulic Thruster Brakes

Get Price Quote

We are a celebrated Trader and Supplier of a wide assortment of Electro Hydraulic Thruster Brakes. These Electro Hydraulic Thruster Brakes are suitable for 440 Volts, 3 Phase A.C. We supply these Electro Hydraulic Thruster Brakes for a wide range of drum size from 100 mm to 600 mm diameter. The thruster rods are connected with the brake by means of an angle lever. As the piston travels upwards the angle lever turns, pushes the brake rod and compresses the brake spring, simulate easily, the brakes lever on the other side of the wheel is retroacted.

Electro Hydraulic Thruster

Get Price Quote

Suni Brand Electro Hydraulic Thrustor / Thruster that is a sturdy Electro Hydraulic device for exerting a smooth controlled upward Thrust on any device with rated capacity from the beginning to the end of the full rated stroke. We are well reckoned as the most preeminent Hydraulic Thrustor/Thruster Manufacturer based in India. Our Crane Electro-Hydraulic Thrustor / Thruster is provided with Clevis-Lug mounting, allowing them to be mounted up to ten degrees either way from the vertical. All the Rubber surfaces are immersed in Oil, there by requiring very less maintenance. One outstanding feature of Suni Brand Thrustor, Thruster is that any Mechanical Overloading cannot cause Overloading of the Electric Motor. If the Load is greater than what the Thrustor Thruster can lift, the Piston will remain at the bottom of the Cylinder and the impeller will rotate harmlessly in Oil. In the absence of Load the Piston stops at the end of the stroke and the Impeller rotates in the Oil as mentioned above. Basically Suni� Brand Electro Hydraulic Thrustor Thruster comprises of a Centrifugal Pump Impeller spinning in Oil there by developing a pressure head. Since there is no outlet, delivery port as in case of a Pump, the pressure developed is impressed on the Piston which is directly coupled to the Load to be lifted. Thus a part of the pressure head is expanded in forming a kinetic head required to lift the Load. At the end of the Lift, either partial or full i e., when the Thrustor,Thruster stalls, it is the full pressure head which is available. Thus the maximum thrust in the stalled position is always higher than the rated thrust. The Centrifugal Pump Impeller is driven by an Electric Motor the capacity of which depends upon the capacity of the Thrustor,Thruster .For example in case of a 18 kg Thrustor,Thruster the Motor is of 0.1 HP and in case of 34 kg it is 0.17 HP. The major components of the Suni Brand Electro Hydraulic Thrustor,Thruster are, a Cast Iron cylinder filled with Transformer Oil, with a Aluminum Piston moving freely in it and a Drive Shaft down the center, through the Piston , to the cylinder. The Impeller draws Oil from above the Piston forcing the Oil beneath the Piston to give it an upward movement in the cylinder with pressure. The pressure is maintained whether the Piston is in motion or has come to a halt at the end of the intermediate position of the upward stroke. During transportation the Oil is drained out from the Thrustor hence at the time of commissioning the system required quantity of Oil needs to be filled up in the Thrustor. It is advisable to use only fresh Grade transformer Oil. The quantity of Transformer Oil required to be filled up in the Thrustor,Thruster depends upon the capacity of the Thrustor. Recommended grade of Transformer Oil is BS 148 or equivalent.

Industrial Thruster Brake

9,460 Per Piece

Thruster Brake

Get Price Quote

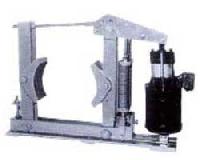

We are offering thruster brake introduction thruster brake is a device used to retard the speed of moving machinery and to stop it accurately to the desired position. The braking force is applied to the brake shoes by a pre-stressed comprising spring. The shoes press on the rotating brake drum retarding its speed and finally stop it. The releasing of the brake drum and compressing of the spring is done by thruster construction rigid welded construction with accessible fixing. Shoes self aligned, easily removable, high grade cast iron fitted with best quality fabric lining. Compression spring are vertically mounted through the guide rod are held securely between guide plates. operation the braking pressure to the shoe is transmitted from the spring by mean of an extremely rigid and simple lever / tie rod mechanism. Braking is smooth and positive. Release of the brake shoes effected by energizing the 3 phase thruster which overcome the spring force & the shoe are moved clear off the drum by lever arm linkage system. The mechanism is balanced to give equal shoe clearance. ›› thruster brakes are suitable for 400 /440volts, 3 phase, 50 hz a.c. Supply. ›› brake drum diameter-100-600 mm. ›› braking torque – 6kg.m. –580 kg.m. ›› easy installation & maintenance ›› reverse action version available ›› self adjusting lining wear mechanism. ›› hydraulic / pneumatic actuator. ›› gentle action, simple control, high performance.

Electromagnetic Thruster Brake

Get Price Quote

Electro Hydraulic Thruster

Get Price Quote

Salient features : This is a spring loaded normally ON Failsafe BrakeConsists of Electro Hydraulic Thruster, Torque Spring and Liner riveted to Brake ShoesWorks on 415 V AC, 3 Phase, 50 Hz supply.Requires Transformer Oil to be filled in the thruster cylinder.Function is to bring to stop, moving / rotating machinery like motor / gearbox.Holds / stops the load in desired place. Instant stop.Prevents jerk due to soft stop.Maintenance free, robust design. Applications : All Material Handling and Lifting Equipments Hoisting : electric wire rope Hoists and Crabs Cross travel and Long travel : EOT / Gantry / Goliath / Derrick Cranes Winches and Conveyors Lifts and Elevators Thruster brake is a device to retard the speed of moving machinery and to stop it accurately to the desired position. The braking force is applied to the brake shoe by a pre-stressed compression spring. The shoes press on the rotating brake drum retarding its speed and finally stopping it. The releasing of the brake and compressing of the spring is done by the Thruster. The thruster shoe brake has a pair of cast iron shoes which are lined up with friction pads. The shoes are hinged on the main arm and the side arm of the brake, each of them having a hinge pin fitted in the base. They are connected to each other on top by a tie rod, which is hinge in the main arm and locked to the swivel block in the side arm, by a lock nut. A crank lever is hinged on the main arm, and the other end is fixed to the top clevis of the thruster by a hinge pin. A brake spring is fixed on the main arm and is pre-locked by a lock nut on the lever. The pre tension in this spring decides the braking torque. The thruster is fitted on the base by a hinge pin. When the thruster is not energized, the brake shoes are pressed on the brake drum fitted on the drive motor shaft and hold it under the effect of braking force provided by the spring. In such a condition, the brake is applied and the drum cannot rotate. When the thruster motor is energized, the thrust provided by the thruster lifts up the crank lever which moves the arms and the shoe brakes away from the brake drum, and releasing the braking force. The spring is compressed and braking energy is stored for the next cycle. Electro Hydraulic Thruster Brake supplier and manufacturerEmbicon Tech Hub is the leading manufacturer and supplier of Electro Hydraulic thruster brake in Rajkot, Mumbai, Maharashtra, Gujarat, Delhi, Pune, Bangalore, Chennai, Ahmedabad, Kolkata, Baroda, Hyderabad, Latur, Nagpur, Udaipur, Telangana, Vijaywada, Surat, Bhopal, Coimbatore, Raipur, Ranchi, Faridabad, Noida, Ghaziabad and all over India.

ELOPHY Thrusters

Get Price Quote

Product Code : ELOPHY-1 Short Decription Thrust Capasity:- 23 Kg; Stroke Length: 50mm Availability : In stock

Thrustor Brakes

Get Price Quote

We are the renowned supplier of thrustor brakes, which are suitable to operate on 400 v, 3 phase ac supply. These brakes are fail safe i.e. They apply when power is switched off. The thrustors are electro-hydraulic devices to exert a smooth straight-line constant force to the brakes. We supply thrustor brakes at affordable rates. attributes dependabledurablesmooth specifications the drum diameter varies from 100 mm to 600 mmbraking torque from 6 kg. M to 580 kg. M.thrustor capacity varies from 18 kgs to 295 kgs.

Thrustor Brakes

Get Price Quote

CRANETECH make Thrustor operated brakes are of 'B' class insulation and continuously rated operating on 3 phase, 415 V. A.C., 50 Hz supply.Advantages: a) Low power consumption b) Minimum maintenance c) Full thrust is maintained from start to finish of stroke. d) Switching operations 720 per hour max. Available brakes sizes from Drum dia. 100mm to 6600 mm

Electro Hydraulic Thruster Brakes

Get Price Quote

Thruster Brakes

Get Price Quote

1 No (MOQ)

kakku heavy duty thrustor brake series kbt brake type drun dia mm max. rated torque (kgm) kbt-100/18 100 6

Brake Thruster

Get Price Quote

Thruster Hydraulic Brake

10,000 - 50,000 Per Nos

thruster drum brakes

Get Price Quote

While packaging, we ensure that the products enclosed are protected from external damaging factors inclusive of vibration, mechanical shock, compression or temperature. Make payment securely with a payment option you are comfortable with. We accept payment through offline as well as online modes. We make sure proper documentation is done.

Electro Hydraulic Thruster

Get Price Quote

A wide range of Electro Hydraulic Thruster that we are offering is precisely designed and developed by adroit professionals at our sophisticated manufacturing unit. Our Electro Hydraulic Thrusters work on a principle of hydraulics. They are easy to mount and dismount. Also, they require low maintenance and power consumption. We are an eminent Electro Hydraulic Thruster Manufacturer and Supplier from Delhi (India). We are backed by a huge distribution network that ensures safe and time delivery of our product. Working On supply of electric power, motor driven centrifugal impeller draws the oil from the low pressure end of the chamber to the high pressure upper end. The piston mounted on the same shaft moves to the upper end with full thrust, till its movement is stopped by the stopper shoulder at the end of the stroke. Pressure build up stops when power is discontinued. Radial blade design of the impeller enables it to rotate both in clockwise and anticlockwise direction. Therefore power supply to star connection can be in any R-Y-8 phase sequence. Features Gentle application & release of brake without jerks & shocks Compact unit Constant magnitude Self-aligned movement Low power consumption Minimum maintenance Easy mounting and dismounting Detail Thruster - ST 520 : A compact 90 watt, 415 Volts, 50 Cycles, 3 Phase Electric motor is directly mounted on the top of a piston. The piston is housed in the C.L tank filled with fluid. The piston moves the fluid from low pressure area to high pressure area. The specially designed impeller which is mounted on the motor shaft produces required fluid pressure. Thruster - ST 535 To ST 13300 : This range of thruster has two thrust rods and a common piston. The motor is mounted on the top cover of the tank. A separator plate divides the tank in two partitions- low pressure side. The spacer bushes control the thruster. The models are suitable for large capacity, higher motor rating and larger thruster forces.