Ultrafine Pulveriser

1 Set(s) (MOQ)

We are offering ultrafine pulverizer. singhasini ultra fine pulverisers are impact type, high speed, air swept, swing hammer type, multipurpose grinding mills capable of grinding soft to medium hard minerals & chemicals up to the hardness of 2.5 ã¢ï¿½ï¿½ 3.0 mohã¢ï¿½ï¿½s. The main mill is supplied with automatic feeder, high efficiency cyclone air separator along with surge drum & air lock valve for better collection efficiency, reverse jet pulse air bag filter dust collector along with automatic cleaning system for bags & air lock valve for better efficiency & a special type of exhaust air centrifugal blower. The material of construction of internal parts of pulveriser main mill, cyclone air separator, bag filter dust collector & exhaust air blower varies as per individual requirement. The ultra fine pulveriser is supplied with digital (automatic) feed controller for maximum optimum feeding.

Brand Name : SINGHASINI

...more

Tray Dryers

SINGHASINI Tray Dryer consists of rigid angle iron frame covered with heavily insulated glass wool on all sides to prevent heat losses from the dryer and mild steel sheet covering , provided with fresh air inlet & adjustable air outlet. The Dryer is finished internally with SS316 / SS304 or Aluminum sheet or heat resistant Aluminum paint to minimize heat losses . Heating is done with electrical heaters / steam heaters or indirect fired hot air generators to achieve required temperature . Cross flow air circulation is maintained in the dryer in such a way that hot air passes over the trays and through it on the sides where it is reheated and recirculated to continue the cycle. A part of air is bled off to reduce moisture content.SINGHASINI tray Dryers are available in 48 , 96 , 192 trays with Aluminum trays and M.S. trolleys . Explosion safety door is available for special application dryer . Dryer is provided with Pre-wired control panel consisting of Digital Temperature Controllers , Contactors , Over Current Relays , Fuses , Indicating Lamps , Push Buttons etc etc.

...more

Sulphur Grinding Mill

1 Set(s) (MOQ)

SINGHASINI SULPHUR GRINDING MILL with integral separator provide an automatic comparatively dust free complete system for medium to fine grinding and classification of Sulphur.The grinding operation in Singhasini Sulphur Grinding Mills is performed under INERT GAS NITROGEN ATMOSPHERE on the principle of attrition and compression, which results due to the centrifugal force generated from the suspended Rollers running inside a stationary Bull Ring. The Sulphur to be pulverized enters the grinding chamber through an automatic feeder and falls onto the mill floor whereby it is scooped up by steel ploughs into the nip space between the rollers and the bull ring where grinding takes place. A constant quantity of air is circulated through the mill and system. The air from centrifugal blower via ‘S’ Bend enters the mill through a series of tangential ports round the base of grinding chamber and sweeps the fine and medium fine Sulphur to the classifier above the grinding chamber leaving no ground material in the chamber and allowing the rollers to work efficiently crushing the coarse Sulphur.The Classifier separates the Pulverized sulphur and coarser particles return back to the grinding chamber for further size reduction. Fine Sulphur is carried by air to the cyclone air separator where air and ground material are separated and collected. The clean air is returned to the blower for close circuit grinding operation. For providing dustless operation, the mill is operated under negative pressure and is equipped with dust collection system where surplus air in the circuit is vented and fine dust is collected in the dust collector bags. DESCRIPTION: The following are the main parts of the Roller Mill: 1.Grinding Chamber. 2.Classifier. 3.Cyclone Air Separator & Tank. 4.Centrifugal Blower. 5.‘S’ Bend. 6.Dust Collector and connecting pipes. 7.Automatic Feeder

Brand Name : SINGHASINI

...more

Spin Flash Dryers

Spin Flash Dryer

Tunnel and cupboard dryers are inherently costly to run, occupy a larger floor space, involve higher number of manual labor and yet the drying rate is slow with much lower thermal efficiency. Compared to this, the FLASH DRYER in its simplest form of mechanical design; is merely a Hot Air Conveyor into which solids, if reasonable free flowing, may be dropped. The material then gets dispersed, thus exposing maximum surface to the drying process. This leads to a very rapid drying rate and the time required is in seconds and not in minutes or hours. Due to the short exposure time and rapid evaporation of water, even though high temperature is employed; the material remains at wet bulb temperature (W.B.T.) until all traces of surface moisture is removed. Thus it is possible to employ high inlet temperature, may be up to 700 C, without affecting the quality of the material, which may even, if it is a heat sensitive one.

...more

Spices Grinding Mill

1 Set(s) (MOQ)

SINGHASINI Manufacturer of SPICE Mills with integral separator provide an automatic dust free complete system for medium to fine grinding of wide variety of spices, ayurvedic and other foodstuffs. They are suitable for handling chilies, turmeric, coriander, mix SPICE, herbs, roots, leaves, saw dust, cattle feed, bran, filtered cakes, sugar and other foodstuffs. Working Principle: SINGHASINI manufacturer of The SPICE MILL is multipurpose economy mill for spices grinding, which can handle lumpy and irregular size materials to produce coarse to medium fine powder. The material is fed to the mill through manual feeder where it is ground by Impact, Shearing, Crushing, and Auto collision of materials. The person feeding the material controls feeding to any desired rate. The material from the feeding hopper is fed directly in the grinding chamber and is conveyed to the periphery of the chamber through a series of beaters, thus gradually reducing them to the desired fineness .The mill is a swing hammer type machine incorporating a centrifugal blower for delivering ground material to cyclone collector. Sieve of required mesh is placed at the bottom of the chamber and allow the pulverised material to be ejected to centrifugal blower. Centrifugal blower makes timely and instant removal of ground material being discharged through fineness controlling sieve at the bottom half of the mill. STANDARD SUPPLY: �SINGHASINI SPICE MILL Complete as per our standard supply fitted with set of hammers, liners, feed hopper, V-pulley for mill and three numbers of M.S. Perforated screen, each of 0.5 mm,1.0 mm, and 3.0mm dia hole. �Rigid M.S. Frame for mounting the machine. �Cyclone collector fabricated out of 14 Swg. M.S. Sheet, with M.S. Ducting. �Set of cloth filter bags. �Mounting arrangement for filter bags.

...more

Spice Making Machine

Manufacturer of SPICE Mills with integral separator provide an automatic dust free complete system for medium to fine grinding of wide variety of spices, ayurvedic and other foodstuffs. They are suitable for handling chilies, turmeric, coriander, mix SPICE, herbs, roots, leaves, saw dust, cattle feed, bran, filtered cakes, sugar and other foodstuffs. manufacturer of The SPICE MILL is multipurpose economy mill for spices grinding, which can handle lumpy and irregular size materials to produce coarse to medium fine powder. The material is fed to the mill through manual feeder where it is ground by Impact, Shearing, Crushing, and Auto collision of materials. The person feeding the material controls feeding to any desired rate. The material from the feeding hopper is fed directly in the grinding chamber and is conveyed to the periphery of the chamber through a series of beaters, thus gradually reducing them to the desired fineness .The mill is a swing hammer type machine incorporating a centrifugal blower for delivering ground material to cyclone collector. Sieve of required mesh is placed at the bottom of the chamber and allow the pulverised material to be ejected to centrifugal blower. Centrifugal blower makes timely and instant removal of ground material being discharged through fineness controlling sieve at the bottom half of the mill.

...more

SCREW FEEDER

Screw Elevators

SINGHASINI Screw Elevators are widely used in all industries for handling of bulk solids . For an efficient operation the design has to be matched for the specific duty and characteristics of the bulk material to be handled . Particular care is required with infeed arrangements for optimum performance . All our elevators are individually designed and manufactured to secure the best results for each application. STANDARD SPECIFICATION : Inclination upto 90° can be accomodated. Gravity feed options are available. OPTIONAL EXTRAS : Clean out doors. Alternative material of construction and finish. Drive arrangement to suit individual requirements. Split casings for easy cleaning. Chute of hopper style inlets. Mobile or fixed units. Dust extraction hoods. Jacketed construction suitable for steam , oil or water. Screw Elevators are tailor made and sizes depend on individual requirement, should you require any information please feel free to get in touch with us.

...more

Rotary Vacuum Dryer

In a chemical Industry, of all the Unit Operations Drying has the widest application and a proper appreciation of the mechanism of drying and the equipment available to resolve a drying problem on an industrial scale is correspondingly important. Most manufacturing operations, particularly in the chemical and metallurgical fields, entail one or more stages where drying is one form or another is carried out. Drying costs account for a large portion of the processing costs associated with the manufacture of Chemicals, Pharmaceuticals, Dye Stuff’s and other products. A Filter Press or a Centrifuge is often used to remove as much water or solvent as possible, there by reducing the heat load in the drying process. Mostly and unfortunately the cake is normally dried in a tray dryer, where the energy consumption is excessively high. Apart from high energy costs, tray dryers also have high labor cost for loading and unloading of the product. Product loss due to manual loading and unloading long drying time and generally dirty operating area.

...more

Rotary Kiln

SINGHASINI Rotary Kiln operated at almost atmospheric pressure consists of a M.S.Cylindrical shell, ranging in length from four to ten times its diameter, into which the charge is fed continuously at one end and is discharged at the other, the movement of the material being due usually to the combined effect of inclination of the shell to the horizontal and the action of internal lifting flights during the rotation of the shell. The latter is usually provided with machined girth rings supported on suitable designed bearings. Rotation of the shell is secured by the action of suitable gearing. Materials like Gypsum , Activated Carbon , Calcium Carbonate etc are calcined in Kilns . The temperatures may be as high as 800 – 900 Deg C , refractory lining is provided in order to achieve high thermal efficiency .

...more

Rotary Feeders

Rotary Dryers

Rotary Dryer operated at almost atmospheric pressure consists of a M.S.Cylindrical shell, ranging in length from four to ten times its diameter, into which the wet charge is fed continuously at one end and is discharged at the other, the movement of the material being due usually to the combined effect of inclination of the shell to the horizontal and the action of internal lifting flights during the rotation of the shell. The latter is usually provided with machined girth rings supported on suitable designed bearings. Rotation of the shell is secured by the action of suitable gearing. Hot air produced from Hot Air Generator (Direct or Indirect ) is injected into the dryer to achieve the required dryness of the material . The discharge end of the Rotary Dryer consists of sealing arrangement , Cyclone and Dust Collector.

...more

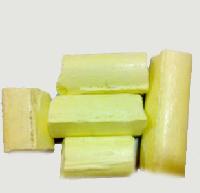

Roll Sulphur

We are offering roll sulphur. Caramel brand we process pure range of roll sulphur ‘caramel brand’ which is available in solid forms and is purified through distillation. The liquid roll sulphur is passed through, in the form of vapor, through a large brick chamber in which it is condensed on the brick wall and then collected as a powder. The entire manufacturing process is completed in accordance with various pharmaceutical standards. Following are the specification of our roll sulphur. Appearance bright yellow, shaped in rolls of 35mm diameter & 50mm – 300mm length (some breakages in to shorter pieces will occur during transportation) properties melting point - 112 0c - 119 0c flash point (pure s) - 188 0c auto ignition temp - 232 0c specifications purity 99.80% (min. As sulphur) ash 0.015% (max.) bitumen 0.02% (max.) acidity 0.01% (max.) moisture 0.5% (max.) solubility in cs2 99% arsenic, selenium and tellurium commercially free applications refining & bleaching of sugar in sugar industry khandsari (brown sugar molasses) units chemical industry

...more

Ribbon Blender

1 Set(s) (MOQ)

Introduction: SINGHASINI RIBBON BLENDER are self contained, compact, dust tight blenders designed for fast mixing of powders. They are used in leading processing plants for mixing materials such as chemicals, foods, drugs, medicines, cosmetics, plastics, synthetics, dyes, fertilizers, insecticides, animal feeds, and many other products. Wherever light to medium mixing is required, there is a Singhasini Ribbon Blender which is ideal for the job. Principle of Operation: Materials with varying densities can be mixed thoroughly in a remarkable short time. Perfect distribution of even smallest quantities added is effected and final product homogeneity is assured. In addition to mixing, shearing action in the interface provides mild kneading. Designed in such a manner that outer ribbon conveys from end towards center, where as inner conveys from center towards end. Rugged Construction: Fabricated out of heavy steel, or any specified material of construction. Design aspects planned for maximum efficiency in leak proof construction. It has fabricated ‘U’ trough having well aligned and balanced shaft which carries ribbons over it. The shaft running in UNI Block Bearing housing with heavy duty self aligning BallRoller Bearings fitted in dust proof housing, gland packing compact unit with built in drive arrangementgear box as specified and supporting legs. Blenders are available from few liters to few thousand liters, tailor made designs are also available.

Brand Name : SINGHASINI

...more

Reverse Jet Pulse Air Dust Collector

SINGHASINI Bag Filters use the well proven air pulse jet cleaning system . The Filter casing has tubular filter sleeves, supported on wire cage . Dirty gas is cleaned by dust particles clinging / stopping on the filter media surface . Clean gas flows on through the filter sleeve and out from the top of filter mounting tube sheet . These Bag filters when used can arrest particles down to 1 micron in size with fairly good collection efficiency . The Tubular Filter Sleeves are neatly grouped in row of multiple elements . While the filters remain on service , through an auto time sequencing system they are back washed by a strong pulse of compressed air which shakes loose the accumulated dirt particles . The dust falls to the collection hopper and is out through Air Lock Valve. We also supply special Bag Filters to handle potentially explosive materials by incorporating Explosion relief valves and using special Anti-Static Filter Media and mounting accessories . For continuous duty only compressed Air / Gas is required besides few Watts control power .

...more

Mixer Reaction Vessels

SINGHASINI Reactors are extensively used by many Chemical Process Industries Viz. Pulp & Paper, Food, Polymerization, Coagulation & Flocculation, Pharmaceuticals, Paint and Breweries etc . Design of Reactor depends on host of features such as R.P.M., Size of Tank, Physical Properties of Fluid, Presence of Baffles and Heat of Reaction etc. Reactor / Agitator / Mixer have wide application in Heat Transfer. Mass Transfer and Dispersion equipment’s. Types of Impellers used are Marine type Propeller, Pitched Blade Turbine, Curved Blade Turbine, Anchor Impeller, Helical Screw Impeller and Flat Blade Turbine . Wide applications warrant the use of various material of construction such as M.S., SS304 / SS316x, Rubber lined, PVC lined etc. Stuffing box and Double Mechanical Seals with Siphon assembly are provided as per requirement . Reaction Vessels / Agitators / Mixers are tailor made equipments and sizes depend on individual requirement, should you require any information please feel free to get in touch with us.

...more

Raymond Mill

ROLLER MILL with integral separator provide an automatic comparatively dust free complete system for medium to fine grinding and classification of MINERALS ORES. The grinding operation in Singhasini 3 5 Roller Mill is performed on the principle of attrition and compression, which results due to the centrifugal force generated from the suspended Rollers running inside a stationary Bull Ring. A constant quantity of air is circulated through the mill and system. The air from centrifugal blower enters the mill through a series of tangential ports round the base of grinding chamber and sweeps the fine and medium fine MINERAL to the classifier above the grinding chamber leaving no ground material in the chamber and allowing the rollers to work efficiently crushing the coarse MINERAL.

...more

Pneumatic Conveyors

Vacuum Conveying System works on negative pressure for conveying the material from one or number of pickup points to one discharge point. This system is best suitable for providing dust free conditions around inlet. The system is composed of pick-up nozzle, divertor valve, discharge lock, exhauster & piping.

...more

Paddle Mixer

Paddle Mixer are twin shaft with adjustable pitch of the paddle which enables variation of capacities and degree of mixing. These are ideal for mixing lumpy materials like filter cakes and materials with high moisture with dry material to make the mixture free flowing.

...more

Metal Recovery from Dross

SINGHASINI Metal Sepration Pulveriser’s are impact type, high speed, air swept, swing hammer type, multipurpose grinding mills capable of grinding & separating heavier metal particles / lumps from the feed dross straight from the ginding chamber on continuous basis through a special type of METAL SEPARATION ATTACHMENT supplied with the machine. The fine metal particles which get air borne along with the ash / dross are separated by the cyclone separator and further by an external vibrating sifter / screen. The main mill is supplied with Manual Feeder, Heavy duty High Efficiency Cyclone Air Separator & Tubular Type Open Dust Collector. The material of construction of internal parts of Pulveriser main mill, cyclone air separator & dust collector varies as per individual requirement. The Pulveriser is supplied withDigital (Automatic) Feed Controller for maximum feeding.

...more

Jaw Crusher

1 Set(s) (MOQ)

SINGHASINI Jaw Crusher is fabricated out of suitable M.S. Plate, heavily reinforced and is of Single Toggle Type which runs on well protected Heavy Duty Bearings. The Crusher is provided with Heavy Duty Fly Wheels for lower power consumption. Fix & Mobile Jaws are replaceable, Cast Manganese Steel. The discharge opening is adjustable.

Brand Name : SINGHASINI

...more

Industrial Dryer

1 Set(s) (MOQ)

We are offering industrial dryer. Tunnel and cupboard dryers are inherently costly to run, occupy a larger floor space, involve higher number of manual labor and yet the drying rate is slow with much lower thermal efficiency. compared to this, the flash dryer in its simplest form of mechanical design; is merely a hot air conveyor into which solids, if reasonable free flowing, may be dropped. the material then gets dispersed, thus exposing maximum surface to the drying process. this leads to a very rapid drying rate and the time required is in seconds and not in minutes or hours. due to the short exposure time and rapid evaporation of water, even though high temperature is employed; the material remains at wet bulb temperature (w.b.t.) until all traces of surface moisture is removed. thus it is possible to employ high inlet temperature, may be up to 700 c, without affecting the quality of the material, which may even, if it is a heat sensitive one. Types of flash dryers: flash drying system are designed for specific problems and may fall into one of the following categories: 1.flash drying without disintegration or pulverisation. 2.flash drying with disintegration. 3.flash drying with pulverisation.

Brand Name : SINGHASINI

...more

Impact Type Pulveriser

1 Set(s) (MOQ)

Singhasini manufacturer of impact pulverisers are high speed, air swept, swing hammer type, multipurpose grinding mills capable of grinding soft to medium hard minerals & chemicals up to the hardness of 3.5 – 4.0 moh’s such as minerals, bentonite, clays, limestone, neeru, dolomite, coal, bauxite, barytes, gypsum, china clay, soap stone, calcite, pyrophillite, mehandi, spices etc. The main mill is equipped with a hopper below which is the star-feeder actuated by pawl & ratchet mechanism. The fine grinding is achieved by compression, shear, abrasion, attrition and impact of hammers beaters on the materials against the replaceable serrated striking plates. The strong suction blower sucks the pulverized product and the air stream inside the mill carries the result product. In between the fan and the grinding chamber (having beaters hammers) is the whizzer classifier consisting of blades with tips tapered to conform the contour of whizzer classifier cone. Counter current is set up at the periphery indicated by arrows; it rejects the coarse material back to the grinding chamber for re-grinding. Clamping the whizzer clamp at a suitable position can control fineness. The entire wearing parts consisting of grinding chamber, whizzer classifier and blower are lined with replaceable lining plates. star features: •lower power consumption. •fineness control. •automatic feeder. •low operation & maintenance cost. •high grinding efficiency. •whizzer classifier. •open circuit grinding. •trap iron pocket. •high efficiency cyclone separator. •tubular air bag filter. •continuous silica separator. •high reduction ratio. •heavy duty construction. •sixty year of experience.

Brand Name : SINGHASINI

...moreBe first to Rate

Rate ThisOpening Hours