Ball Mill

Get Price Quote

Ball Mill Machine

Get Price Quote

Batch Ball Mill

Get Price Quote

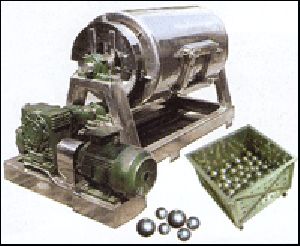

Ball Mill Motor Driven

Get Price Quote

Ball Mill

Get Price Quote

Ball Mill

Get Price Quote

Ball Mill

Get Price Quote

Ball Mills

Get Price Quote

Ball Mills

Get Price Quote

Ball Mill

Get Price Quote

Ball Mill

Get Price Quote

Ball Mill

Get Price Quote

Ball Mill

Get Price Quote

Ball Mill

Get Price Quote

Ball Mill

Get Price Quote

Planetary Ball Mill

Get Price Quote

Ball Mill

Get Price Quote

Ball Mill

Get Price Quote

Ball Mill

Get Price Quote

Ball Mill

Get Price Quote

Vertical Planetary Ball Mill

Get Price Quote

Vertical Planetary Ball Mill

Get Price Quote

Ball Mill Grinder Machine

Get Price Quote

Ball Mills India

Get Price Quote

Ball Mills

Get Price Quote

Ball Mills

Get Price Quote

Ball Mills

Get Price Quote

Solid Carbide Ball Nose End Mills

Get Price Quote

Ball Mill

Get Price Quote