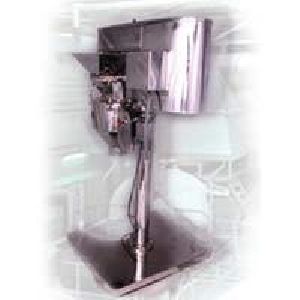

Multi Mill Machine

Get Price Quote

Multi Mill Machine

Get Price Quote

Multi Mill

Get Price Quote

Multi Mill

Get Price Quote

Multi Mill Machine

Get Price Quote

Multi Mill

95,000 / Piece

Multi Mill Machine

Get Price Quote

Multi Mill

120,000 - 150,000 / Piece

Multi Mill

Get Price Quote

Multi Mill

Get Price Quote

Multi Mill Machine

1 - 5 / Bag

Multi Mill

Get Price Quote

Multi Mill

Get Price Quote

+4

+4

Multi Mill Machine

Get Price Quote

Multi Mill Machine

Get Price Quote

+1

+1

Multi Mill Machine

200,000 - 600,000 / Piece

Multi Mill

Get Price Quote

Multi Mill

Get Price Quote

Multimill

Get Price Quote

Multi Mill

Get Price Quote

Cone Mill Machines

Get Price Quote

Multimill

Get Price Quote

Multi Mill

Get Price Quote

Multi Mills

Get Price Quote

Multi Mill

Get Price Quote

Multi Mill Machine

Get Price Quote

Multi Mill Machine

Get Price Quote

Multi Mill

Get Price Quote

Multi Mill

Get Price Quote

Multi Mill

Get Price Quote