Pultruded FRP Cooling Towers

Get Price Quote

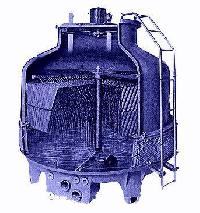

Induced-Draft Cooling Towers Made Of Frp. The Structure Of Our Pul. Frp Series (support Beams And Columns) Is Made Of Composite Continuous Fiberglass Pultruded Sections That Comply With Cti Std 137 And Conform To Astm E84d With A Flame Spread Rating Of Below 25. Pultruded Frp Cooling Towers Are Positioned Over A Concrete Basin. Just As Our Sgct Series , Sgct Provides Its Customers With Scale Drawings Of The Concrete Cement, Including Locations And Production Drawings Of All Pipe Fittings In 2d Or 3d, The Size Of A Single Cell Ranges From 3m X 3m To 15m X 15m. When The Concrete Basin Is Ready On Site, Sgco Sends Its Assembly Teams To The Job Site, Where One Team Sets The Pultruded Frp Structure, And The Other Furnishes The Cell Once The First Team Has Erected It.Detail : Pultruded Frp Cooling Towers Have Become An Alternative Solution To Traditional Concrete Cooling Towers, Since In Many Cases They Cost Less And Their Erection Time Is Much Shorter Than That Of Cooling Towers Made Entirely Of Concrete. In Addition, Pultruded Frp Towers In Many Cases Offer Superior Corrosion Resistance.Options : Additional Weil Layers To Increase Corrosion Resistance Pultruded Frp Hand Rails, Walkways, And Ladders Low-Noise Fans. Ss 304 Nut Bolt Or Ss 316. Elevated Basin For Optimal Use Of Space. Features : Pultruded Fiberglass Polyester Field-Erected Cooling Towers Heavy-Duty Cooling Towers Designed For Industrial Applications Optimal Thermal Performance Design Highly Resistant To Corrosive Environments

Pultruded Cooling Tower

Get Price Quote

1 Piece(s) (MOQ)

ICTMCo. offers field erected Pultruded FRP cooling towers. These cooling towers are designed using Pultruded FRP sections, FRP sheets for cladding, Stainless steel for fasteners and other hardwares. Properties of Pultruded FRP gives the cooling tower distinct advantages over other material of construction like concrete or timber. Engineering at ICTM CO. gives shape to the finest of cooling towers whose aesthetic beauty make cooling tower area very special place in the plant. The strength of Pultruded FRP can be compared with that of steel. With FRP the question does not stop at performance but carries on to beauty and aesthetics. With wide range of colours to choose from, the colour of cooling tower can be matched to rest of the plant. No wonder when ever a timber cooling tower reaches its end of its life, there is always a demand to convert it to Pultruded FRP cooling tower. For large field erected cooling tower Pultruded FRP structural members are used for constructing the cooling tower. Pultrusion is an industrial process that is dedicated to continuously process Reinforced Plastic having constant cross sectional shape like I, C, U, H, flat panels etc. Reinforcing fibers are pulled through a Plastic liquid impregnation bath through rollers etc. and then through a shaping die followed with a curing action. It produces products which meets high structural requirements, high weight to strength performances, electric requirements etc. In case of Pultruded FRP Cooling Towers materials are shipped to the site and cooling tower is erected first by putting up the structural framework and then fan deck, torque tube, mechanical assembly, fills, casing sheets etc. Pultruded FRP based cooling towers have structures having proven Braced Frame Design. These structures are connected to the ground with steel angles and base plates anchored and grouted to the basin. Hardware used at all the places are stainless steel. No piers and pilasters are used in the structure. Frame, Casing, Fan deck, Fan cylinder, staircase, railing, light poles, ladders etc are all of FRP. Wherever necessary anti skid surfacing is used for safety of Operation and Maintenance personnels.

Best Deals from Pultruded Cooling Tower

Pultruded FRP Cooling Towers

Get Price Quote

We use superior-grade packaging as barrier protection for our products against dust, moisture, mechanical damages and logistical jostling. Our products packaging is premium. Located in Vadodara(India), our company is involved in making available wide array of products that are in conformance with the industry standards.

Pultruded Cooling Tower

Get Price Quote

We are offering pultruded cooling tower. paltech has developed the capabilities right from manufacturing to commissioning of pultruded frp codling towers with most attractive features. The pultruded frp cooling towers are very strong, light weighted and non corrosive with much longevity. The consumption of time for construction and installation of pultruted frp cooling towers are very less in comparison to the conventional cooling tower such as rcc and ( wooden cooling towers. Besides, the pultruded frp cooling towers are best suited for sea water application as a replacement for old and large wooden cooling towers or fresh installation of new cooling towers in place of conventional cooling tow6rs. Paltech pultruded frp cooling towers are available in single cell capacity upto 5000 m3/hr arid multi cell capacity of any quantity in counter flb~ design with film fill and splash fill. Paltech, offers to its valued customers the most efficient and unmatchable pultruded frp cooling towers with the assurance of quality and reliability. Structure is made of pultruded fibreglass material. Hardware hot dip galvanized is used to withstand corrosion. Stainless steel hardware is available at extra cost. Casing is made of pultruded frp and corrugated frp sheets of adequate thickness. fan deck is made of robust and strong pultruded frp panels and sheets. Frp fans are of proven design provided by indian institute of technology. Fan cylinder is made of tough & durable frp and grp material. Drift eliminator paltech uses efficient pvcd drift eliminator in cellular and full wave design to reduce water losses and fan air pressure resulting in low energy consumption by fan. Fill of film type or-splash type as per requirement of client is provided. Nozzles made up of pp and pvc, non clogging types are provided for optimum efficiency. Drive shafts duly balanced in ss and hdg steel materials in hollow construction are provided. Gear box of spiral bevel or spiral bevel cum helical, design is validated by indian institute of technology. These are made to meet requirement of std-ill of cti, usa and agma standards. Prior to shipment, load testing of each and every gear box, is carried out at factory to provide our clients zero defects gear box.

Pultruded Frp Cooling Tower

200,000 - 2,000,000 Per Set

1 Set(s) (MOQ)

We are offering counter flow cooling tower. 50 tr to 1500 tr single and multi cell option steel and frp construction, balarka aerodynamic frp axial flow fan high efficient fills, nozzle, drift standard motor.

FRP Pultruded Cooling Tower

100,000 - 200,000 Per Pair

1 Set(s) (MOQ)

<p>Jai Bhawani offers Pultruded FRP Cooling Towers which are designed using Pultruded FRP Sections. The Sections are manufactured using a Mechanized Process Called Pultrusion. Pultrusion uses the extrusion Principle of Producing, having constant cross section to give strength. Jai Bhawani offers fiberglass ppultruded main structure in induced draft counter flow cooling towers.</p>

Pultruded Frp Cooling Tower

35,000 - 3,000,000 Per piece

1 no (MOQ)

Pultruded Frp Cooling Tower

50,000 Per Square Feet

Pultruded Frp Cooling Tower

Get Price Quote

The cooling tower was initially manufactured to reuse precious water after a great amount of groundwater had been utilized for industry to make land subsidence a social issue. It might be taken as “water chiller” utilizing common powers. Our cooling tower solutions really help in water resource recycling.

Pultruded FRP Cooling Towers

Get Price Quote

Towertech Global manufactures pultruded FRP cooling towers and general pultruded cooling towers using top grade raw materials and FRP materials. Towertech is among largest Pultrusion manufacturing facilities across the world. It offers cutting edge technology in Pultrusion and Pullwinding processes. Here, in the TowerTech facility, clients can avail superior pultrusion solutions such as pultruded range of cooling towers and many other structural profiles.The rising queries and demand for using the composites in cooling tower applications have been driven by several factors because of the longevity and ease of use. TowerTech Global manufactures and offers comprehensive range of composite products that can be used in both dry and wet cooling towers.

Pultruded Frp Cooling Tower

1,000,000 - 10,000,000 Per 1

Pultruded Cooling Tower

Get Price Quote

Pultruded cooling tower is made of Fibre-Reinforced Plastic (FRP ) is known for its high corrosion-resistance capabilities. FRP is a composite material.. The fibres are usually glass, carbon, or aramid, although other fibres such as paper or wood. Pultuded FRP is produced using pultrusion technology, and has become the most common structural material for small cooling towers. It offers lower costs and requires less maintenance compared to reinforced concrete, which is still in use for large structures. FRP cooling tower are commonly used in the aerospace, automotive, marine, and construction industries.

Semi Pultruded Cooling Towers

Get Price Quote

These cooling towers are designed using Main Structure with Pultruded FRP sections, other structure with MSHDGI OR Timber as per client preference with FRP sheets for cladding, MSHDG fasteners and other hardware. Semi Pultruded cooling towers are design on customer demand. Its unique design of increases life span of cooling tower with minimum expense. Complete technical and dimensional detail about RCC cooling towers can be obtained from our sales and marketing department.

Pultruded Frp Cooling Tower

Get Price Quote

Pultruded FRP based cooling towers have structures having proven Braced Frame Design. These structures are connected to the ground with steel angles and base plates anchored and grouted to the basin. Hardware used at all the places are stainless steel. No piers and pilasters are used in the structure. Frame, Casing, Fan deck, Fan cylinder, staircase, railing, light poles, ladders etc are all of FRP. Wherever necessary anti skid surfacing is used for safety of Operation and Maintenance personnels. The cell size that can be been designed is 18x18 meters and is capable to handle fan motor power 250 HP/cell. The flow rate capacity of the Pultruded FRP Cooling Towers can range from 500 m3/hr to 40000 m3/hr. ICTMCo. offers field erected Pultruded FRP cooling towers. These cooling towers are designed using Pultruded FRP sections, FRP sheets for cladding, Stainless steel for fasteners and other hardwares. Properties of Pultruded FRP gives the cooling tower distinct advantages over other material of construction like concrete or timber. Engineering at ICTM CO. gives shape to the finest of cooling towers whose aesthetic beauty make cooling tower area very special place in the plant. The strength of Pultruded FRP can be compared with that of steel. With FRP the question does not stop at performance but carries on to beauty and aesthetics. With wide range of colours to choose from, the colour of cooling tower can be matched to rest of the plant. No wonder when ever a timber cooling tower reaches its end of its life, there is always a demand to convert it to Pultruded FRP cooling tower. For large field erected cooling tower Pultruded FRP structural members are used for constructing the cooling tower. Pultrusion is an industrial process that is dedicated to continuously process Reinforced Plastic having constant cross sectional shape like I, C, U, H, flat panels etc. Reinforcing fibers are pulled through a Plastic liquid impregnation bath through rollers etc. and then through a shaping die followed with a curing action. It produces products which meets high structural requirements, high weight to strength performances, electric requirements etc. In case of Pultruded FRP Cooling Towers materials are shipped to the site and cooling tower is erected first by putting up the structural framework and then fan deck, torque tube, mechanical assembly, fills, casing sheets etc.

Pultruded Cooling Towers

Get Price Quote

The Structure of Cooling tower is fabricated of Pultruted FRP profile which are free from corrosion. The whole cooling tower is fabricated in pieces & bolted together to facilitate easy shifting

Pultruded Cooling Tower

Get Price Quote

These Heavy Duty Cooling Towers can be designedUp to 18 x 18 meters in Each Cell Type to handle maximum water flow rate of 5000m³HrCell . NATIONAL NPCT Cooling Towers Pultruded FRP Structures are completely assembled using SS Bolt Nut Washers . The Pultruded FRP Structure is known as one of the best material of construction for Cooling Towers as it wont Corrode , rust or wrap in harsh environments .

Pultruded Frp Cooling Tower

Get Price Quote

We manufacture Natural Draft , Induced Draft Cross Flow Counter Flow type, Treated Timber Cooling towers in single cell Multi cell construction. There is no capacity limitation in multicell design. We have designed and supplied multi-cell tower of 9000 m3hr capacity, each cell having 2250 m3hr circulating water and 15°C range at 4°C approach. Mechanical draft towers have either direct driven or gear driven fan depends upon the capacity of each cell. Normally small capacity towers (Aprx. Single cell capacity upto 200 m3hr and DT 15°C ) are direct driven and higher capacity towers are gear driven. We also manufacture single stripping special purpose cooling tower for DT upto 50°C.

Pultruded Cooling Tower

Get Price Quote

The Structure of Cooling tower is fabricated of Pultruted FRP profile which are free from corrosion. The whole cooling tower is fabricated in pieces & bolted together to facilitate easy shifting The tower casing is made of FRP which encloses the surface area serves to isolate air stream, which passes over the surface area.The casing shape is of curtain type which reduce frictional resistance of air and aid air flow pattern.

Pultruded FRP Cooling Towers

Get Price Quote

Along with manufacturing a wide variety of new cooling towers due to our flexible, project oriented Engineering and designs, Canara has diversified, expertise in conversion of old timber cooling towers to pulturded FRP cooling towers. Many cooling tower users prefer to repair existing old timber cooling towers, which either have out lived their life or damaged prematurely due to bad quality of materials or other reasons. In reality if the overall condition of the existing cooling tower is bad and requires a major structural repairs, then it is technically and economically advised to convert the old timber cooling tower to pulturded FRP cooling tower. During repairing of old timber cooling towers, only part of the bad quality items are replaced, so un replaced items need to be replaced after some time. Practically repairing of old timber cooling towers takes place every 1- 2 years, which proves very costly affair. Moreover partially repaired old timber cooling tower may fail, collapse partially or fully, which will be dangers in all aspects.

FRP pultruded cooling towers

Get Price Quote

These cooling towers are light in weight and corrosion resistant. These are durable products that have high strength. The construction and installation time is lesser as compared to conventional models or wooden cooling tower. Pultruded range of cooling towers supplied by TowerTech Global is not only efficient in performance, but also known for its quality, longevity, and reliability. These are ideal for sea water application as their structure is built with pultruded fiberglass material. Hardware hot dip galvanized is used by manufacturers to make the surface corrosion resistant. Stainless steel hardware can be availed at extra cost. Casing of the tower is manufactured with pultruded FRP sheets that have adequate thickness.

Pultruded Cooling Tower

50,000 Per 500000 Set

10 Set(s) (MOQ)

We manufacture & Supply Pultruded FRP Structure for Cooling tower of 500CMH to 5000CMH in various length

Pultruded Cooling Tower

Get Price Quote

Butterfly valve Natural draft AT Series Cooling Tower PVC splash fills for counter flow Cooling Tower High efficiency FRP fan cylinder Drift eliminator for 0.0005% drift loss New generation FRP fans Composite drive shafts

Pultruded Cooling Tower

Get Price Quote

Pultruded profiles dominate the cooling tower market as the material of choice for field erected cooling towers. Pultruded profiles offer many positive attributes; it is recognized as the best structural material for cooling tower construction. General Composites, an advanced and integrated composite design, development and manufacturing facility, is one stop destination for composite solutions. The company is equipped to deliver excellence from the simplest to the most complex application. General composites follow CTI 137 for composite products and components being used for both dry and wet cooling towers.

Pultruded Frp Cooling Tower

Get Price Quote

Pultruded Frp Cooling Tower, cooling tower fan balancing

Pultruded Frp Cooling Tower

Get Price Quote

Pultruded Frp Cooling Tower, Cooling Tower Spares, glycol chillers

Pultruded Frp Cooling Tower

800,000 - 500,000,000 Per piece

01 piece (MOQ)

Pultruded Frp Cooling Tower, wooden cooling towers

Pultruded Frp Cooling Tower

Get Price Quote

Pultruded Frp Cooling Tower, cold storage unit, commercial cold storage

Pultruded Cooling Tower

Get Price Quote

Pultruded Cooling Tower, frp pultruded profile, Bottle Shaped Cooling Tower

Pultruded Frp Cooling Tower

Get Price Quote

Pultruded Frp Cooling Tower, wooden cooling towers, Supply, repairing

Pultruded Frp Cooling Tower

Get Price Quote

Pultruded Frp Cooling Tower, Cooling Towers, cooling tower nozzle