Laser Cutting Machine

2,800,000 - 4,500,000 Per piece

1 NO (MOQ)

cnc lazer cutting machine power size 3kw2500x65002,782,5002,520,0001500x30002,047,5001,942,500 6 kw 2500x65002500x6500(pallet)2500x12000 2500x12000(wo/bed) cutting thickness:msss3 kw16 mm8 mm 6 kw24 mm16 mm

Q Switch ND Yag Laser Machine

Get Price Quote

Best Deals from Optical Machine

Open Fiber Laser Cutting Machine

Get Price Quote

Product Description : Fiber laser power source options from 300W ,500w, 1KW, 2KW,3KW Structure : Gantry, Double drive Light alloy beam (Y axis) to provide High dynamic performance. The optical path changes while the sheet remains still, thus the processing efficiency is high X, Y axis adopts high quality gear and rack, reduction gear, ensuring life and precision for a long time. The system is equipped with section dust collector to improve the working environment. The area beneath the cutting table is divided into several sections. During the cutting process, only the ducts directly beneath the cutting head are open for fume extraction. The ducts in the other sections remain closed to improve dust collection.

Micron Excimer Laser

Get Price Quote

Scanning Laser Therapy Machine

350,000 Per Units

Yag Laser Tattoo Removal

749,000 - 750,000 Per Piece

Laser Engraving Machine

Get Price Quote

Ophthalmic Lens Meter

Get Price Quote

Micro Laser Welding Machine

920,000 Per Units

Laser Cutting Facilities

Get Price Quote

All the benefits of Trumpf technology It combines a rugged drive system Machine construction with a TruCoax 2.5 KW diffusion cooled RF laser resonator Cost-effective Productive Laser Cutting system in a small footprint. Requires half of the floor space of a typical 5 x 10 foot machine

Steel Metal Laser Cutting Machine

2,600,000 Per Piece

1 Piece (MOQ)

Laser Marking System

Get Price Quote

PERMANENT Laser marking is permanent and indelible marking process, which stands against wiping, scuffing, impacts, wear and tear, can only be removed by grinding or surface removal. Thus laser - marking sustains authenticity of your brand against sort of tempering NON-CONTACT TYPE Laser marking is non-contact type process. It does not produce any deformation in product unlike in punching, stamping, pneumatic pin, vibratory pencil etc. This gives accurate and aesthetic marking independent of hardness of material. FLEXIBILITY Laser marking is highly flexible process compared to any other marking process. It can mark any images and fonts without changing any punch, die, stencil etc. unlike other conventional process. AESTHETIC/ACCURACY Since laser can produce very fine beam with accuracy in micron, many accurate and micro details with precision can be marked with laser marking. Laser can produce aesthetic images which otherwise difficult to create with other marking process. NO PRE/POST PROCESSING Since Laser marking is non-contact type, no pre or post processing is required, which in turn significantly increase marking productivity. LOW OPERATING COST Laser marking helps significantly in cutting operating cost by reducing labor cost, tool cost, consumable cost, set up time, rejection improved cycle time. AUTOMATION One of the prime advantage of laser marking is that it can be automized and can be integrated with any online process. With support of software, even variable serial nos., batch nos., date of bar code can be marked.

Ocean Optics System

Get Price Quote

If a spectrometer is the heart of an Ocean Optics system, and its light source the lungs, then fibers and probes are the circulatory system – the conduits through which light travels to reach the extremities and bring life to the measurement of a sample.Our patch cords come in a variety of core sizes for optimizing throughput. Bifurcated fibers and splitters are Y-shaped assemblies for routing light from one location to two others.

CNC Laser Cutting Machine

3,000,000 Per unit

Laser Welding Machine

Get Price Quote

RODOMACH is a system Integrator and manufacturer of PillowPlate machines. Our company has developed into an innovative machine builder which focuses on the development, construction and supply of specialized machinery. Pillow Plates, also called dimpled plates or thermo plates, consists of two stainless steel sheets that are laser welded together by welding a custom circle weld pattern. Then the plate is inflated by using water pressure, which creates a specific single or double embossed profile – the pillow plate, through which the cooling or heating is conducted. The thickness and the spot pattern are determined by the pressure requirements

Laser Shaft Alignment System

10,000 Per Piece

Laser Engraving Machines

250,000 Per Piece

1 Piece (MOQ)

Laser Cutting Machine

Get Price Quote

CNC CO2 LASER CUTTING MACHINE (AMADA) We have the capability of cutting preformed shapes, profile, angle and mor Power - 2000 Watts Steel Plates - 12 mm Stainless Steel Plates - 8 mm Aluminium – 4 mm Working Area – 2500 mm X 1250 mm.

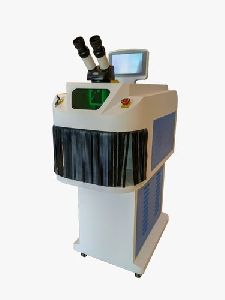

Jewelry Laser Welding Machine

650,000 Per unit

Optical Machinery

Get Price Quote

Optical Machinery, Lap Cutter, Angle Polisher, Spherical Generato