DTC Temperature Controller

Get Price Quote

Highlights : Calibration through keys Memory Retention for Set Point Input Type Field Configurable Output Configurable For Heating or Cooling Configuration disabled in user mode Offset Adjustment in Proportional Mode

Pid Temperature Controller

Get Price Quote

Best Deals from Process Control Equipment

PT100 R000 Temperature Sensor

999 Per Piece

10 Piece (MOQ)

Custom Made Temperature Controller HI-EC10002

Get Price Quote

Programmable Logic Controller

Get Price Quote

A PROGRAMMABLE LOGIC CONTROLLER (PLC) is an industrial computer control system that continuously monitors the state of input devices and makes decisions based upon a custom program to control the state of output devices.

RTD Sensors

Get Price Quote

In the contemporary market, we have made our stand among the renowned RTD Temp Sensors Manufacturers as well as Suppliers. The RTD Sensors are suitable for various industry types such as foodservice processing, medical research, textile production, plastic processing, petrochemical processing and microelectronics. Our RTD Temperature Sensors are primarily used as temperature sensors in automation, furnaces and temperature control.

Programmable Logic Controller

Get Price Quote

1 Piece (MOQ)

Non Contact Temperature Controller

Get Price Quote

Water Level Controller

Get Price Quote

This is the simplest Basic water level Controller with indicator it is the most economical and energy efficient product from Sri Digitek, Two sump levels, Two over head tank indication. Flow, motor on, dry run, power on. Features: The water level controller can switch on or switch off the pump, to maintain the pre defined water level at the storage tanks.Low AC Voltage sensing circuit to avoid polarization of electrodes in water. These special stainless steel plastic molded conductive electrodes are Long life sensors and do not require frequent cleaning or replacement.

2MLL-EFMF PROGRAMMABLE LOGIC CONTROLLER

Get Price Quote

1 Box (MOQ)

model no : 2mll-efmf product type : programmable logic controller enet i/f fast, fiber inspected by h.m.go sc type connector origin : made in korea manufacture : honeywell usage : indutrial automation warranty : 1 year

Intelligent Power Factor Controller

Get Price Quote

We offer intelligent power factor controller, elmeasure has introduced yet another innovative product called ipfc. It helps in controlling the power factor thereby avoiding the penalty imposed by the electricity supply company. it also saves cost, increases internal electrical system capacity and improves voltage drop at the point of use. This leads to an efficient electrical system. Unlike in conventional controllers, elmeasure’s power factor controller senses three phase voltage and current. This ensures the perfect controlling of power factor in unbalanced load conditions. It’s rightly called intelligent as it increases the life of the correction capacitor, by controlling based on the capacitor bank switching history. It is not just a pf controller but also a true multifunction meter. It has v, a, hz, w, var, and wh parameters in addition to pf. Hence this product is truly power packed. It also has rs485 communication option. This product can be used in all incomers as a pf controller and also as a multifunction meter.

Process Controller

Get Price Quote

5 Piece(s) (MOQ)

We offer process controller, process monitor. Number of inputs : the number of inputs is the total number of signals sent to the controller. This number includes process variable signals such as temperature, pressure, level, speed, etc., and s tatus inputs such as on/off. number of control outputs : the number of control outputs is the total number of outputs used to control, compensate or correct the process. This number relay outputs as well as switches and rs232 serial pot .which activate or deactivate control devices. controller inputs : dc voltage input: controllers accept analog dc voltage inputs such as ±5 v, 0 -10 v. currentloop(transmitter) input: current loop (transmitter) inputs include analog inputs such as 0 - 20 ma and 4 - 20 ma. Or any other current-loop signal from a transmitter. resistive / potentiometer input : controllers accept analog inputs from a resistor or potentiometer which monitors the process variable(s). frequency input: a pulse or frequency input is used to measure and indicate a process variable for feedback to the controller. switch / relay input: controllers accept a discrete, on/off voltage signal from a sensor or switch which monitors the process. control signal output: switch / relay output / rs232: the output is a switch or relay that can be "on" or "off". general applications : control, monitor or record temperature, pressure, flow, production, totalizing and storing based on preset timing or real time clock through rs232 communication pot to save energy, time and man power to always increase the production capacity with lesser wastage in more ways.

Water Level Controller

Get Price Quote

Complying with all set industry and quality norms, we have established a niche in Manufacturing and Supplying high quality Water Level Controller since 1995. Backed with up-to-date technology and hard working team, we are known for supplying high performance, error free and precise Water Level Controller. Our quality analysis team ensures that Water Level Controllers are durable and have longer service life. We have earned the trust of our clients for supplying both Off-the-shelf and customized quality Water Level Controller at reasonable price. We always deliver all orders on time.

Winding Temperature Controller

Get Price Quote

Some equipments , transformers and electrical macheniery dissipate heat during its operation. If the heat dissipation increase beyond the tolerance value then it might damage some important equipment permannently.

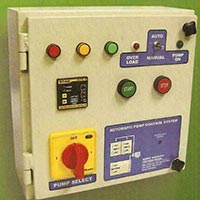

Alarm & Pump Controller

Get Price Quote

Liquid Level Controller (APC-1) is used to automatically start & stop the pump for filling the tank or emptying the tank with alarm indication With liquid level inputs from the Magnetic Float Switch fitted in the sump and over head tank, (APC-1) controller can be used for PUMP UP or PUMP DOWN operation. Alarm relay is provided to indicate abnormality in the process like liquid level raised beyond high level setting or drops below low level setting in the Overhead or sump tanks. Technical Specification :Supply Voltage : 95 - 280V AC, 50 Hz.Power Consumption : 3VA.Inputs : High High Level : Magnetic Float Switch Input (Close on Rising Level). High Level : Magnetic Float Switch Input (Close on Rising Level). Low Level : Magnetic Float Switch Input (Close on Falling Level). Low Low Level : Magnetic Float Switch Input (Close on Falling Level). PU/PD Mode Selection : Pump_UP/Pump-Down Mode is selected by Slide Swtich Provided on rear end.Outputs : Pump Relay No Contact : Potentail free 1No Rated 10Amps @ 250V AC. Pump-UP-Mode : Closes when the liquid level falls below low Low level reaches at or above high level Pump-Down- Mode : Closes when the liquid level reaches at or above High level and Opens when the liquid level falls below Low level Alarm Relay NO Contact : Potentail free 1No Rated 10Amps@250V AC. Closing When the Liquid level goes above High High level or Liquid level falls below Low Low Level and Opens when the liquid level Normal conditionor by Alam ACK button provided on front panel

Water Level Controller

800 Per Piece

5 Piece(s) (MOQ)

MAC1 Speed Controller

3,400 Per Piece

Programmable Logic Controller

Get Price Quote

We are a distinguished Importer and Supplier of Programmable Logic Controller in Karnataka, India. The Programmable Logic Controller or programmable controller is a digital computer, which is used for the automation of typically industrial electromechanical processes, such as control of machinery on factory assembly lines, amusement rides, or light fixtures. PLCs are used in many machines, in many industries. PLCs are designed for multiple arrangements of digital and analogue inputs and outputs, extended temperature ranges, immunity to electrical noise, and resistance to vibration and impact. Programs to control machine operation are typically stored in battery-backed-up or non-volatile memory. A PLC is an example of a "hard" real-time system since output results must be produced in response to input conditions within a limited time, otherwise unintended operation will result. Programmable Logic Controller, PLC, or Programmable Controller is a digital computer used for automation of typically industrial electromechanical processes, such as control of machinery on factory assembly lines, amusement rides, or light fixtures. PLCs are used in many machines, in many industries. PLCs are designed for multiple arrangements of digital and analog inputs and outputs, extended temperature ranges, immunity to electrical noise, and resistance to vibration and impact. Programs to control machine operation are typically stored in battery-backed-up or non-volatile memory. A PLC is an example of a "hard" real-time system since output results must be produced in response to input conditions within a limited time, otherwise unintended operation will result. Programming : Early PLCs, up to the mid-1990s, were programmed using proprietary programming panels or special-purpose programming terminals, which often had dedicated function keys representing the various logical elements of PLC programs.[2] Some proprietary programming terminals displayed the elements of PLC programs as graphic symbols, but plain ASCII character representations of contacts, coils, and wires were common. Programs were stored on cassette tape cartridges. Facilities for printing and documentation were minimal due to lack of memory capacity. The oldest PLCs used non-volatile magnetic core memory. More recently, PLCs are programmed using application software on personal computers, which now represent the logic in graphic form instead of character symbols. The computer is connected to the PLC through Ethernet, RS-232, RS-485, or RS-422 cabling. The programming software allows entry and editing of the ladder-style logic. Generally the software provides functions for debugging and troubleshooting the PLC software, for example, by highlighting portions of the logic to show current status during operation or via simulation. The software will upload and download the PLC program, for backup and restoration purposes. In some models of programmable controller, the program is transferred from a personal computer to the PLC through a programming board which writes the program into a removable chip such as an EPROM Functionality : The functionality of the PLC has evolved over the years to include sequential relay control, motion control, process control, distributed control systems, and networking. The data handling, storage, processing power, and communication capabilities of some modern PLCs are approximately equivalent to desktop computers. PLC-like programming combined with remote I/O hardware, allow a general-purpose desktop computer to overlap some PLCs in certain applications. Desktop computer controllers have not been generally accepted in heavy industry because the desktop computers run on less stable operating systems than do PLCs, and because the desktop computer hardware is typically not designed to the same levels of tolerance to temperature, humidity, vibration, and longevity as the processors used in PLCs. Operating systems such as Windows do not lend themselves to deterministic logic execution, with the result that the controller may not always respond to changes of input status with the consistency in timing expected from PLCs. Desktop logic applications find use in less critical situations, such as laboratory automation and use in small facilities where the application is less demanding and critical, because they are generally much less expensive than PLCs. Features : Control panel with PLC (grey elements in the center). The unit consists of separate elements, from left to right; power supply, controller, relay units for in- and output.The main difference from other computers is that PLCs are armored for severe conditions (such as dust, moisture, heat, cold), and have the facility for extensive input/output (I/O) arrangements. These connect the PLC to sensors and actuators. PLCs read limit switches, analog process variables (such as temperature and pressure), and the positions of complex positioning systems. Some use machine vision.[4] On the actuator side, PLCs operate electric motors, pneumatic or hydraulic cylinders, magnetic relays, solenoids, or analog outputs. The input/output arrangements may be built into a simple PLC, or the PLC may have external I/O modules attached to a computer network that plugs into the PLC. Scan time : A PLC program is generally executed repeatedly as long as the controlled system is running. The status of physical input points is copied to an area of memory accessible to the processor, sometimes called the "I/O Image Table". The program is then run from its first instruction rung down to the last rung. It takes some time for the processor of the PLC to evaluate all the rungs and update the I/O image table with the status of outputs.[5] This scan time may be a few milliseconds for a small program or on a fast processor, but older PLCs running very large programs could take much longer (say, up to 100 ms) to execute the program. If the scan time were too long, the response of the PLC to process conditions would be too slow to be useful. As PLCs became more advanced, methods were developed to change the sequence of ladder execution, and subroutines were implemented.[6] This simplified programming could be used to save scan time for high-speed processes; for example, parts of the program used only for setting up the machine could be segregated from those parts required to operate at higher speed. Special-purpose I/O modules may be used where the scan time of the PLC is too long to allow predictable performance. Precision timing modules, or counter modules for use with shaft encoders, are used where the scan time would be too long to reliably count pulses or detect the sense of rotation of an encoder. The relatively slow PLC can still interpret the counted values to control a machine, but the accumulation of pulses is done by a dedicated module that is unaffected by the speed of the program execution. System Scale : A small PLC will have a fixed number of connections built in for inputs and outputs. Typically, expansions are available if the base model has insufficient I/O. Modular PLCs have a chassis (also called a rack) into which are placed modules with different functions. The processor and selection of I/O modules are customized for the particular application. Several racks can be administered by a single processor, and may have thousands of inputs and outputs. Either a special high speed serial I/O link or comparable communication method is used so that racks can be distributed away from the processor, reducing the wiring costs for large plants. Options are also available to mount I/O points directly to the machine and utilize quick disconnecting cables to sensors and valves, saving time for wiring and replacing components. User Interface : See Also : User interface and List of human-computer interaction topics PLCs may need to interact with people for the purpose of configuration, alarm reporting, or everyday control. A human-machine interface (HMI) is employed for this purpose. HMIs are also referred to as man-machine interfaces (MMIs) and graphical user interfaces (GUIs). A simple system may use buttons and lights to interact with the user. Text displays are available as well as graphical touch screens. More complex systems use programming and monitoring software installed on a computer, with the PLC connected via a communication interface. Communications : PLCs have built-in communications ports, usually 9-pin RS-232, RS-422, rs-485, Ethernet. Various protocols are usually included. Many of these protocols are vendor specific. Most modern PLCs can communicate over a network to some other system, such as a computer running a SCADA (Supervisory Control And Data Acquisition) system or web browser. PLCs used in larger I/O systems may have peer-to-peer (P2P) communication between processors. This allows separate parts of a complex process to have individual control while allowing the subsystems to co-ordinate over the communication link. These communication links are also often used for HMI devices such as keypads or PC-type workstations. Formerly, some manufacturers offered dedicated communication modules as an add-on function where the processor had no network connection built-in. Programming : PLC programs are typically written in a special application on a personal computer, then downloaded by a direct-connection cable or over a network to the PLC. The program is stored in the PLC either in battery-backed-up RAM or some other non-volatile flash memory. Often, a single PLC can be programmed to replace thousands of relays.[7] Under the IEC 61131-3 standard, PLCs can be programmed using standards-based programming languages. A graphical programming notation called Sequential Function Charts is available on certain programmable controllers. Initially most PLCs utilized Ladder Logic Diagram Programming, a model which emulated electromechanical control panel devices (such as the contact and coils of relays) which PLCs replaced. This model remains common today. IEC 61131-3 currently defines five programming languages for programmable control systems: function block diagram (FBD), ladder diagram (LD), structured text (ST; similar to the Pascal programming language), instruction list (IL; similar to assembly language), and sequential function chart (SFC).[8] These techniques emphasize logical organization of operations.[7] While the fundamental concepts of PLC programming are common to all manufacturers, differences in I/O addressing, memory organization, and instruction sets mean that PLC programs are never perfectly interchangeable between different makers. Even within the same product line of a single manufacturer, different models may not be directly compatible. Security : Prior to the discovery of the Stuxnetcomputer worm in June 2010, security of PLCs received little attention. PLCs generally contain a real-time operating system such as OS-9 or VxWorks, and exploits for these systems exist much as they do for desktop computer operating systems such as Microsoft Windows. PLCs can also be attacked by gaining control of a computer they communicate with.[9] Simulation : In order to properly understand the operation of a PLC, it is necessary to spend considerable time programming, testing, and debugging PLC programs. PLC systems are inherently expensive, and down-time is often very costly. In addition, if a PLC is programmed incorrectly it can result in lost productivity and dangerous conditions. PLC simulation software such as PLCLogix can save time in the design of automated control applications and can also increase the level of safety associated with equipment since various "what if" scenarios can be tried and tested before the system is activated.[10] Redundancy : Some special processes need to work permanently with minimum unwanted down time. Therefore, it is necessary to design a system which is fault-tolerant and capable of handling the process with faulty modules. In such cases to increase the system availability in the event of hardware component failure, redundant CPU or I/O modules with the same functionality can be added to hardware configuration for preventing total or partial process shutdown due to hardware failure. PLC compared with other control systems : PLCs are well adapted to a range of automation tasks. These are typically industrial processes in manufacturing where the cost of developing and maintaining the automation system is high relative to the total cost of the automation, and where changes to the system would be expected during its operational life. PLCs contain input and output devices compatible with industrial pilot devices and controls; little electrical design is required, and the design problem centers on expressing the desired sequence of operations. PLC applications are typically highly customized systems, so the cost of a packaged PLC is low compared to the cost of a specific custom-built controller design. On the other hand, in the case of mass-produced goods, customized control systems are economical. This is due to the lower cost of the components, which can be optimally chosen instead of a "generic" solution, and where the non-recurring engineering charges are spread over thousands or millions of units.

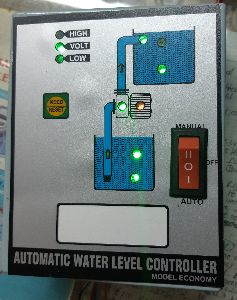

Automatic Water Level Controller

Get Price Quote

We are offering automatic water level controller. Exceptional display : shows clear indication of water levels in the overhead tank and sump tank, blinking blue light indicates water flow to overhead tank automatic switching on and off of the motor as per the water level in the tank. controls voltage variation: the motor is cut-off if there is low supply voltage to protect the motor. surge protection for spikes and abnormal voltage overshoots. dry run protection: the device detects dry running of motor and the supply to the motor is cut-off as a safety precaution to save the motor. auto-manual operation: has an easy operable auto-manual side leap switch. indications for motor: green indicates motor on, red indicates dry running of motor. side leap switch enables to power on/off and to directly switch on the motor if needed.

Digital Temperature Controller

1,200 Per Piece

Allen Bradley PLC

18,000 Per unit

Humidity Controller

Get Price Quote

Combining our expertise with the technology that we possess, we take the responsibility to deliver utmost quality humidity controller to the customers. With our brilliant logistics network, we are capable to deliver the orders within the postulated time frame.

Digital Process Controller

2,000 Per Piece

Temperature Controller

Get Price Quote

We provide Temperature Controller that facilitates the controlling of the entire application in an easy, repeatable and affordable manner. Furthermore, our Temperature Controller is available in variegated specifications and support various types of thermocouple like J, K, E, T, L, N, B, C, S & R; RTDs 100Ω Plt. NIST, 100Ω Plt. DIN, 120Ω Ni Industrial, 1000Ω Plt. DIN with differential input (-10 to +10 MV DC) and process input (0 to 20 MA DC, 0 to 10 VDC). The major advantages of Temperature Controller are fuzzy logic technology, din sizes and operator field selectable programming options. Basic Features Fuzzy logic Auto tune Fully adjustable PID Auto and manual control

Automatic Water Level Controller

2,500 - 3,000 Per piece

1 piece (MOQ)

Temperature Controller

975 - 30,000 Per Piece

Wireless Water Level Controller

Get Price Quote

DX-WLS-01 wireless water level controller system DX-WLS-01 wireless water level controller system offers a portable, efficient and high performance solution for Automation. The system operating in the 2.5 GHz frequency band with maximum 100 meters range. The system consists Transmitter & Receiver unit. Main Features.Easy to set up & maintainStable & reliable operationProven RF wireless technologyUser-friendlyStable coverage range 100 metersHighly interference-resistantReal-time interference signal analysisAutomatic data encryptionUltra low power microprocessorReal-time Water level displayEnergy-saving sleep modeExternal antennaPower consumption:

Unimod Evaluation Kit

Get Price Quote

The vCAN Evaluation Kit acts an evaluation platform using which the vCAN UniMod based development can be carried on without the need for any other hardware.The vCAN-UniMod can be plugged on to the kit and its inputs & outputs can be configured and verified for desired functionality.This kit can also be used to develop customised versions of the vCAN-UniMod module.

Intelligent Power Factor Controller

Get Price Quote

We offer intelligent power factor controller, elmeasure has introduced yet another innovative product called ipfc. It helps in controlling the power factor thereby avoiding the penalty imposed by the electricity supply company. it also saves cost, increases internal electrical system capacity and improves voltage drop at the point of use. This leads to an efficient electrical system. Unlike in conventional controllers, elmeasure’s power factor controller senses three phase voltage and current. This ensures the perfect controlling of power factor in unbalanced load conditions. It’s rightly called intelligent as it increases the life of the correction capacitor, by controlling based on the capacitor bank switching history. It is not just a pf controller but also a true multifunction meter. It has v, a, hz, w, var, and wh parameters in addition to pf. Hence this product is truly power packed. It also has rs485 communication option. This product can be used in all incomers as a pf controller and also as a multifunction meter.

CTK Series Closed Loop Tension Controller

22,000 - 30,000 Per Piece

1 Nos (MOQ)

CTK Controllers are closed-loop tension measurement and control instruments, designed to be used with a hysteresis brake or to act as a monitoring tension meter.The PLC control closed-loop type allows for interfacing with PLC and providing required current to the hystresis brake.Closed-loop type-this model measures and displays real-time running tension, while simultaneously comparing it to the preset tension values. Its built-in software compensates output current to the hysteresis break accordingly for precise, stable and consistent tension.Stand-Alone type - this model does not provide curent output. They are used to measure and display real time tension. It also alerts (Output alarm) the user when tension is detected to be out of preset range (the upper and lower tension limits can be preset.)