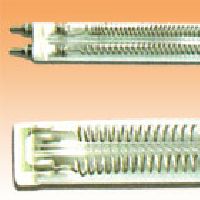

TWIN TUBES IR HEATERS

QUARTZ GLASS The quartz glass is very pure and provides good transmission and temperature resistance TWIN TUBE The unique twin tube design offers high radiation power and very good mechanical stability allowing emitters of lengths up to 3.5 meters. Emitters are available in Short Wove, Medium Wave, or Long Wave versions. That gives you the possibili-ty to select the optimum wavelength for the material to bo hooted. Dimensions and filaments are matched to requirements. GOLD/ WHITE COATED Twin Tube Infrared Heater is made by virtue of a gold & white coated which con emit heat directly to the product. A coat-ing on the infrared emitters reflects the infrared radiation. Consequently the infrared radiation impinging on the product is virtually doubled. FEATURES Infrared heaters can be matched to material characteristics - following higher process speeds and less energy consumption Directed heat only where needed Infrared ovens needs less space Non contact or medium needed Short response times of infrared heaters for switch on / switch off

...more

twin tube medium wave infrared heater

The unique twin tube design offers high radiation power and very good mechanical stability allowing emitters of lengths up to 3.5 meters. Emitters are available in Short Wove, Medium Wave, or Long Wave versions. That gives you the possibility to select the optimum wavelength for the material to bo hooted. Dimensions and filaments are matched to requirements.

...more

Thermocouples

Thermocouples & thermo resistances Mgo insulation with grounded or ungrounded junctions. Sheathes & types available for all temperatures. Special shapes & fittings can be offered

...more

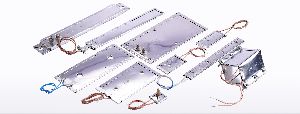

STRIP & PLATE HEATERS

APPLICATION In rubber & bakelite mouldings presses, cutting & sealing machines or where temperature upto 300° C is required. CONSTRUCTION Rust resistant steel sheathed, nichrome ribbin wire wound heating elements, insulated with mica, complete with rigid terminal. Connections were ever required. STANDARD SIZES & CAPACITIES Length - 10" to 30" Width - 1", 13/8", 11/2", 17/8", 21/2", 4" etc. Volts - 250 Watts - 250 to 1250

...more

Silica Heater

Sheathing–This type of heaters have quartz silica tube sheathing, closed from bottom. Rubber cap with terminal wires are mounted on the top. Heater terminals are fixed very firmly with the outer wires. It consist of non-sinkable heating element, as the heater is suitable for vertical installation only. This heater is designed to heat-up the solutions rapidly as the same have more watt density than the rod type heater. This heater is also available with built in thermostat.

...more

SILICA & GLASS CASED IMMERSION HEATERS

APPLICATION To heat-up various acidic solutions where no metal withstands. Generally this heater is used in electroplating industries. The heater is operated vertically only. CONSTRUCTION Sheathing–This type of heaters have quartz silica tube sheathing, closed from bottom. Rubber cap with terminal wires are mounted on the top. Heater terminals are fixed very firmly with the outer wires. It consist of non-sinkable heating element, as the heater is suitable for vertical installation only. ADVANTAGE This heater is designed to heat-up the solutions rapidly as the same have more watt density than the rod type heater. This heater is also available with built in thermostat.

...more

SHORTWAVE IR HEATERS

Infrared heat is transmitted directly in the form of electromagnetic rays, at a velocity of approx. 300,000 km/sec i.e. at the speed of light. IR is therefore not only the "fastest form of heat", but is also suitable for particularly demanding applications such as vacuum technology and clean room conditions. Infrared heat is particularly economical on energy compared to other heat sources because it acts quickly, directly on product. Short Wave IR emitters are suitable for all applications in which the attainment of high temperatures in the shortest possible time is what counts.Infrared heat is transmitted directly in the form of electromagnetic rays, at a velocity of approx. 300,000 km/sec i.e. at the speed of light. IR is therefore not only the "fastest form of heat", but is also suitable for particularly demanding applications such as vacuum technology and clean room conditions. Infrared heat is particularly economical on energy compared to other heat sources because it acts quickly, directly on product. Short Wave IR emitters are suitable for all applications in which the attainment of high temperatures in the shortest possible time is what counts.Infrared heat is transmitted directly in the form of electromagnetic rays, at a velocity of approx. 300,000 km/sec i.e. at the speed of light. IR is therefore not only the "fastest form of heat", but is also suitable for particularly demanding applications such as vacuum technology and clean room conditions. Infrared heat is particularly economical on energy compared to other heat sources because it acts quickly, directly on product. Short Wave IR emitters are suitable for all applications in which the attainment of high temperatures in the shortest possible time is what counts. APPLICATIONS PET preform heating in stretch blow moulding machines. Paint baking. Rubber coating drying. Soldering fusing in PCB industries. Sterilizing / mirror coating drying in glass industries. Printing link drying in offset machines. Powder coating curing. Impregnation plants. Paper coating drying. All type of laminations. Preheating prior to embossing. Screen printing curing to T-shirts & textile

...more

SHAPED TUBULAR HEATERS

Versatile in shape & loading. Sheath material suitable to the application and temperature for variety of heating application. SINGLE ENDED TUBULAR HEATER S Single Ended Tubular Heating Elements are of similar construction as our standard tubular elements. They terminate at one end which can simplify wiring and installation. These are most commonly used in moulds and other heat transferring metal parts as well as open air applications and immersion applications. Tubular Heaters are available in a variety of sheath materials with temperature capabilities up to 870°C SPECIALTY SHAPES TUBULAR HEATER Specialty Shaped Tubular Heating Elements are of similar construction to our standard tubular elements. These shapes can greatly increase rigidity to the element. Heaters that are clamped to a surface have greater surface contact allowing for greater heat conductivity. Tubular Heaters are available in a variety of sheath materials with temperature capabilities up to 870°C

...more

IMMERSION ROD HEATERS

To heat up water, oils, chemicals, alkaline & other solutions, electroplating baths etc. Sheathing heavy gauge, s.s., titanium, m.s., or lead bonded tube with closed bottom with flange (for vertical operation), suitable to the ordered size. It is available in easy to replace the coil system. Unscrewing the top terminal plate can easily stretch the element out. Heating elements - helical coiled wire element is uniformly inserted in the refractory blocks to distribute even heat throughout the surface of the heater. Vertical heaters are provided with non-heating zone are required from the top. Water tight terminal cover is also available with the above heater.

...more

ring heaters

HS FS ring elements owing to their convenient shape & sizes, adapt themselves readily to variety of machines and appliances for which other type of heaters are not suitable. They are being fitted for heating platens, dies of presses. They are in use for melting of glue, wax, easily fusible metals like leads, tin, solder, hot plates, popcorn machines, high speed packing machines, difussion pumps, kettles, large coffee percolators & wash boilers etc.

...more

quartz infrared heaters

APPLICATION Ideal for drying adhesives, ink, paint & epoxy bonding/curing. Laminating. Shrink Packaging. Thermoforming Plastics. Other process requiring fast penetration of heat into metals, wood, synthetic fabrics & plastics. CONSTRUCTION Quartz emitters provide medium wavelength radiation and can be the most preferred source of heat when rapid heater response is needed. The modules are comprised of a series of quartz tubes running parallel to each other within a highly reflective steel housing. Each tube contains a coiled resistance wire available in a variety of wattages and voltages. The large variety of sizes, shapes, and watt densities allows quartz emitters to be highly useful in zoning arrangements such as plastic thermoforming sheet-fed applications where complex heating patterns are needed, high-speed roll-fed processes, and machines requiring precise zone control because they are small in size, and can easily be put in larger panels. FEATURES Standard Industry Sizes & Rating up to 40W /sq. Inch. For fast heating & better reflection it is also available in Quartz Clear tubes / gold coated tubes etc. Highly reflective rugged Steel housing construction. Standard winding pattern gives uniform heating over entire face of heater. Optional built-in type K or J T/C available. Ideal for systems requiring small area zooming & close control of process. Best when used at radiation distances of 4-10” from work. Suitable for horizontal or vertical operation with tubes in horizontal plane. Can be design in different Voltages. More responsive heat-up & cool-down.

...more

open refractory heaters

Open Cartridge Heaters are widely used as immersion heaters or as air heater selecting appropriate sheath materials for heating various types of chemicals, oils & water OR air & gases. They are available in various diameters and lengths as per customers' specifications. However the standard diameters are from 8 mm OD to 75 mm OD. They can be designed for vertical as well as horizontal installation with required heating and non-heating zones. Max. Watt density: 30.W/Sq. inch. Max. surface temp. 400° C.

...more

OPEN HEATING ELEMENTS

These elements are used in quick air heating processes and where quick cooling is also required. These can also be used in oven and dryers with cover guard. CONSTRUCTION Helical coil of nichrome wire is inserted into porcelain blocks uniformly mounted on insulated metal sheet. Straight wire can also be wound around insulators as required in different applications CAUTION This element cannot be used where corrosive vapour, or moisturised atmosphere is there. There should be proper guards in front of open wires

...more

Micro Tubular Coil Heaters

application heaters are used in various applications, due to their being intrinsically reliable and highly versatile. They were first designed for a very specific application, the differential heating of plastic injection nozzles, and later become invaluable in the most diverse and demanding applications. Aerospace, railway, chemical, metalworking and food industry, glass and paper indus-try, automotive, packing, medical industry.. All have taken advantage from the use of heaters, with their wide range of possible shapes and their fitness to an unlimited number of applications. construction microtubular coiled heaters are manufactured to a revolutionary design, which makes them the best choice in the most demanding conditions. The resistive wire is uniformly distributed in a compacted mgo insulation, with a crni-steel outer protection sheath. The heaters are annealed after manufacturing, thus acquiring a high malleability that allows their being subsequently bent into any complex shape, with extremely narrow bending radius. features a very wide contact surface results in exceptionally high levels of thermal conductivity towards the body that needs to be heated. optimal insulation results in very long life duration heavy-duty construction results in very high resistance to mechanical shocks operation temperature up to 700°c (1300°f) very low mass results in extremely low thermic inertia optional built-in thermocouple for high-resolution temperature measuring (j-type standard; k-type on request) unlimited range of possible shapes obtained from the straight heater heaters can be incorporated into brass or aluminium castings available in cross section 2.4mm x 4.2mm & 3.3mm x 3.3mm.

...more

Mica insulated Nozzle Heaters

APPLICATION Low cost electric heating of plastic processing, rubber vulcanizing, Drums, Barrels & cylinders etc. CONSTRUCTION Mica insulated Heaters consist of electric resistant ribbon / round wire element covered with zinc plated MS, Brass or SS sheet with clamps. Size & terminal connections as per requirement. CONNECTION For contact accessories, cable fittings, clamping devices, fixed & braided connection, heat resistant, flexible insulation with metal braided cable housing of any convenient length, connection boxes & types according to the band heatersdimensions, power & type of power supply. STANDARD SIZES & CAPACITIES Max. Watt density: Any convenient Wattages up to 25 W/Sq. inch. Max. Surface Temp. 300 Deg. C. Supply (Volt) – Any convenient Voltage under the pre condition that it should be technically feasible

...more

Mica Heating Elements

Mica heating elements To heat up dies, platterns, flat, round bottoms, kettles etc. Electric resistant wire element is wound on mica blocks uniformly to heat full surface area. Element is insulated with mica. Sheathing is made out of rust resistant steel sheet fabricated as per the required size.

...more

medium watt density cartridge heaters

Cartridge heaters are recommended wherever the performance of cartridges is not fully needed. In construction, the same materials used in are used, though manufacturing technology is simpler, due to lower watt density, and therefore the whole process is more economical. Cartridges have one or more U-bent spirals in a cartridge core of compacted magnesium oxide, with the spirals nearer to the axis of the cartridge than in heaters, as heating power is lower and thermal conductivity of com-pacted magnesium oxide is highly sufficient to spread heat, therefore with total reliability and safety even in extreme work conditions. Due to their simple construction, cartridges are perfect for being shaped in various ways for the application needed. They can have cold sections at ends, and/or with differentiated watt densities or indepen-dent circuits for separate sections.

...more

HALF & FULLY SHEATHED RING HEATERS

HS / FS Ring Elements owing to their convenient shape & sizes, adapt themselves readily to variety of machines and appli-ances for which other type of heaters are not suitable. They are being fitted for heating platens, dies of presses. They are also in use for melting of glue, wax, easily fusible metals like leads, tin, solder, hot plates, valves, flanges, brooders, vulcaniz-ers, popcorn machines, high speed packing machines, diffusion pumps, tank bottoms, kettles, large coffee percolators & wash boilers etc. Being sheathed on one side only, it has very little residual heat and stands up to 650°C temperature for its surface area. Elimination of the sheath on the contact side puts the rock hard refractory in direct contact with the heated surface, thereby providing slightly faster heat-up. Half Sheath elements can be used where the protection provided by the full sheath is unnecessary. Chrome steel sheath on one side and edges, other flat side is the bare refractory. Coiled electric resistant wire embedded inside. And steel terminal studs with nuts and washers Fully Sheathed Heaters (both sides metal) provides extra protection from rough handling & usage, especially when there are chances of falling any liquid on it.

...more

Flexible Heaters

Helical heating coil insulated with fibre glass sleeve & tape suitable for maximum 100 Deg. C. skin temperature. It will have terminal leads with ceramic connector at either end. To heat viscous fluids by wrapping it around pipe, flasks, beakers, etc. Anti-condensation applications in motor, generator sets etc.Max. Watt Density: 5 W/sq. Inch

...more

Flanged Immersion Heater

Flanged immersion heaters are one of the most widely used methods for heat-ing gases and liquids (such as water, oil, heat transfer fluid and corrosive solutions). Designed for use in tanks and pressurized vessels, they are easy to install and maintain to provide heat for many processes. The direct immersion method is energy efficient and easily monitored and controlled. Hot Water Storage Tanks Warming Equipment Preheating All Grades of Oil Food Processing Equipment Cleaning and Rinsing Tanks Heat Transfer Systems Process Air Equipment Boiler Equipment Freeze Protection of Any Fluid Flanged Immersion Heaters consist of bent tubular elements welded or brazed into a flange and provided with wiring boxes for electrical connections. Flange heaters are installed by bolting to a matching flange welded to the tank wall or nozzle. A wide selection of flange sizes, kilowatt ratings, voltages, terminal enclosures and sheath materials make these heaters ideal for all types of heating applications.

Length : 8" to 72'

...more

Finned Air Heaters

Strip finned heaters consist of refractory insulated heating element, covered with zinc plated ms or ss sheet with fixing holes. Finned heaters are for more coverage of suface area. They are used where high velocity of air to be heated APPLICATION These heaters are generally used where high temperature required in smaller space, as the same is having much watt density than strip heaters. This heater is also applied in air ducts, comfort heaters, load resistors, recirculating ovens etc Wire would coil is inserted into metallic tube (M.S., S.S., Incolloy etc.) compactly insulated by magnesium oxidised fused powder. The terminals are brazed ruggedly. Rust resistant steel finns are mounted on the tube alongwith the holding clamps. Stainless steel or incolloy sheathed spirally would coil embedded in centre with Mgo. With M4 SS terminal studs. Finns are available either in zinc plated M.S. or S.S. Fully annealed heater is also available for bending / shaping as per requirement. It can be installed either with M.S. brackets, nipple assembly or ferrul type compression fit assembly, suitable to fit in existing duct as per requirement.

...more

EMBEDDED STRIP HEATERS

Rectangular section heater, insulated with compacted MgO for quicker & even heating & better life span. Max. Watt density: 40 W/Sq. inch. Max. surface temp. 650° C APPLICATION Dryers, Ovens , External heating for tanks & vessels.

...more

Duct Heaters

APPLICATION This type of heater is used where forced hot air is required through smaller ducts of ovens, dryers, hot air blast, space heat-ing etc. Primary Room Heating (Central or Zone) Supplemental Room Heating (Heat Pumps) Air Tempering (Outside Air) Preheating (Make-Up Air) Reheating (Overcooling applications) Industrial and Commercial Buildings CONSTRUCTION Pairs of tubular (with - w/o finns) heaters are mounted in a chamber with easy to replace facility. Complete with terminal cover on the top or side isolated from the heating zone

Length : 18", 24"

...more

\\\'D\\\' TYPE CARTRIDGE HEATERS

Cartridge heaters are most frequently used for heating metal parts by insertion into drilled holes. The ‘D’ heater is designed especially for platen, die or mould commercial heating applications where the holes are poorly drilled or worn through age. Independent expansion of each section of the when energized, creates intimate contact with the wall of the hole. Split Sheath design Improved conductive heater Easily inserted and removed from long holes Incolloy Sheath for long life at extreme temperatures Compacted to maximum density for excellent element to sheath heat transfer and dielectric strength

...moreBe first to Rate

Rate ThisOpening Hours