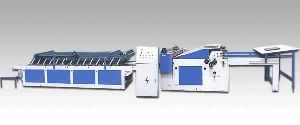

Semi Automatic Flute Laminating Machines

Get Price Quote

Use and Characteristics: 1.Automatic feeding bottom paper, frontage pushing face paper, feeding paper fast and lower work intensity.Localization bottom never go beyond, suitable for laminating the paperboard together and for laminating the 2.paperboard with the A/B/C/D/E corrugated cardboard together.3.Bottom paper and face paper can fore-and-art adjustment, easy to laminate together.4.Feeding glue system are automatically controlled by liquid relay, thickness of glue can adjust. Gluing uniformity, lower glue cost.5.Control panel, electromagnetism clutch without touch point relay, position is monitored by photoelectric switch, digital automatic counter.6.High precision laminate, the finished products are of smooth surface edge and of high intensity.Whole structure is compact, with beautiful appearances and high work efficiency.

BZJ-A Semi Automatic Flute Laminating Machine

Get Price Quote

Main characteristics : BZJ-A series semiautomatic laminator , this machine adopt automatic supply the glue by photoelectric check. Main parts and pressure part all use the import speed control system. Work steady and low noise, electrical components use international famous brand, high reliably. Nearly no trouble. BZJ-A series semiautomatic laminator, this machine push paper part. Ensure the body paper never runs forward with upper paper, electro-optical tracking. Auto count, with the characteristics of high products and low consume, beautiful and easy operation, it is your ideal product.

Best Deals from Automatic Flute Laminating Machine

Semi-Auto-Flute-Laminator machine

Get Price Quote

Automatic feeding bottom paper, frontage pushing face paper, feeding paper fast and lower work intensity. Localization bottom never go beyond, suitable for laminating the paperboard together and for laminating the 2.paperboard with the A/B/C/D/E corrugated cardboard together. 3.Bottom paper and face paper can fore-and-art adjustment, easy to laminate together. 4.Feeding glue system are automatically controlled by liquid relay, thickness of glue can adjust. Gluing uniformity, lower glue cost. 5.Control panel, electromagnetism clutch without touch point relay, position is monitored by photoelectric switch, digital automatic counter. 6.High precision laminate, the finished products are of smooth surface edge and of high intensity. Whole structure is compact, with beautiful appearances and high work efficiency.

Automatic Flute Laminating Machine

Get Price Quote

Suitable for Offset printed board to 2 ply 4 ply pasting. High performance work horse Capable of around the clock productivity. More than 100 installations across India. Several multiple machine users Can also be put to use for board to board pasting..

Automatic Flute Laminating Machine

Get Price Quote

Automatic Flute Laminating Machine, Automatic Board Punching Machin

Fully Automatic Servo Type Flute Laminator Machine

1,600,000 - 2,200,000 Per Set

1 piece (MOQ)

Description:High-Speed & Precision Lamination – Ensures accurate pasting of printed sheets onto corrugated boards with minimal errors. Fully Automatic Operation – Reduces manual labor, increasing efficiency and productivity.Advanced Servo Control System – Provides precise registration for top and bottom sheets.Automatic Feeding System – Ensures continuous and smooth feeding of paper and corrugated sheets. High-Accuracy Registration System – Uses sensors and alignment technology for perfect positioning.Automatic Glue Application – Even and controlled glue distribution for strong adhesion and minimal wastage.Fast Drying Mechanism – Reduces production time by ensuring quick bonding and drying.Heavy-Duty Rollers & Construction – Made with durable materials for long-term industrial use.User-Friendly Touchscreen Control Panel – Digital interface for real-time monitoring and adjustments. High Production Output – Optimized for large-scale operations with consistent quality.Energy-Efficient Design – Low power consumption with high operational efficiency.Safety Features – Includes emergency stop buttons, safety sensors, and protective covers.

Automatic 5Ply Flute Laminator

Get Price Quote

Bottom Paper Feeding Both bottom feeding part adopt lead edge feeding, the wheels use unidirectional bearing (reduce the wear of rubber wheels). The wide rubber wheels ensure that the E, F, and G corrugated does not deform. Top Sheet Feeding Mechanism Equipped with high speed feeder, and together with Becker vacuum pump. The front and rear of feeder are controlled by the servo motor. After input paper size, it will be automatically positioned. Both paper lifting and forwarding sucker can freely adjust to ensure that whether thick or thin paper can be delivered rapidly and smoothly. Electrical System Mainly using Siemens electric system to ensure machine stability, high efficiency and low failure. Using man-machine interface and PLC combination, display all the information on the screen. Automatic Lubrication System Lubricate the bearing regularly to prolong the service life of the bearing and save the cost.