Mild Steel Sheet Rolling Machine

150,000 / Piece

Guide Forming Machine

Get Price Quote

Single Shaft Auto Roll Cutting Machine

1,230,000 / Set

Thermal Paper Roll Printing Machine

Get Price Quote

+3

+3

Roller Embossing Machine

10,000 / Piece

Manual Roll Marking Machine

Get Price Quote

Spinning Rolling Machine

130,000 / Piece

Electric Sheet Rolling Mill Machine

Get Price Quote

Flute Roll Corrugation Machine

200,000 / Set

Roll Forming Machine for Shutter Making

Get Price Quote

EDGE Inking Machine with Roller System

1 - 2 / Piece

3 Roller Pipe Bending Machine

235,000 / Piece

Batch Roller Machine

Get Price Quote

Steel Rolling Machine

Get Price Quote

Roller Coaster Ice Cream Machine

325,000 / Number

Roll Turning Lathe Machine

Get Price Quote

Plate Rolling Machine

16 /

Fabric Rolling Machine

300,000 / Units

Round Rolling Machine

Get Price Quote

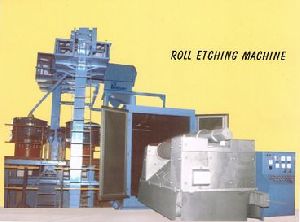

Roll Etching Machine

Get Price Quote

Hydraulic Thread Rolling Machine

Get Price Quote

Roll Forming Machine for making 'C' Channels / Lipped C Purlins

Get Price Quote

TRIPLE ROLLING MACHINE

Get Price Quote

+2

+2

Jewellery Rolling Machine

100,000 - 120,000 / piece

Roll Bending

Get Price Quote

+3

+3

Jewellery Rolling Machine

35,750 - 112,500 / piece

SMT Paper Roll Cleaning Machine

Get Price Quote

Paper Roll To Sheet Cutting Machine

Get Price Quote

Mechanical Plate Rolling Machine

Get Price Quote

Shaft Less Slitting and Rewinding Machine for Plotter Paper Rolls

Get Price Quote