Vibro Dryer

Get Price Quote

Driers important if parts are to be painted or plated. Vibro Dryer is used for drying of wet components. The dryer is filled with water absorbing media like corncob. The wet components when tumbled with corncob, it gets nice wiping action and Stain Free Drying is achieved. Longer process time here enhances luster of the components. The time cycle can be infinitely varied after which the unload flap is flipped into position and parts are discharged via the unloading screen. The cob remains in the bowl. Bhalani Industries range of driers ensures parts dry stain and corrosion free following the mass finishing process. This is particularly important if parts are to be painted or plated as a final operation. Driers are an essential part of the complete mass finishing solution. Feature : Continuous / recirculatory operation. Can be automated and added onto the total system. Variable speed controller. Sound and dust control lids. Rugged heavy duty special vibratory motor. In built separation arrangement.

Vibro Dryer

Get Price Quote

Features Rugged heavy duty special vibratory motor In built separation arrangement Continuous / recirculatory operation Can be automated and added onto the total system Temperature controller Finishing Media Ceramic Media: Ceramic Media for Heavy Cutting, Deburring, Descaling, Edge Radiusing & Fine Finishing of different types of work pieces. Ceramic media are used on hard ferrous & non¬ferrous metal like, Mild steel, stainless steel, hard casting, EtcPlastic Media: Plastic Media for polishing, deburring & finishing of non-ferrous components & casting. Plastic media have low density so this media is used on soft metals such as Aluminium, Zinc and alloys of Brass, Copper Etc....Steel Media: Steel Media are used for burnishing to obtain lustre & mirror finish. This media generally used for S.S., copper, brass component Etc...Corn Cobs: Corm Cobs used for drying process. Corn cobs have replaced Saw dust as drying media. Corn cobs are also used for polishing of ferrous & nonferrous components, Etc... User Industries / Institutions • Vibrator & Centrifugal machine manufacturing units • Forgings Bicycle parts mfg. • Sewing machine parts mfg. • Automobile components mfg. • Bearing cages • rollers and retainers Hand tools • Spectacle frames & components • Surgical instruments • Ortho tools mfg. • Clutch plate mfg. • Buckle mfg. • Zinc, aluminium and other die casting • Sheet metal pressing Pressed parts mfg. • Control gear parts • Electroplating Lock & key mfg. • Textile machinery parts mfg. • Advanced Ceramics • Non-ferrous parts of brass, copper, etc. • Castings & sintered components Switches mfg. • Jewellery & cutlery items

Best Deals from Vibratory Dryer

vibratory dryer

71,000 Per Number

1 Number (MOQ)

Vibro Dryer

Get Price Quote

Driers important if parts are to be painted or plated. Vibro Dryer is used for drying of wet components. The dryer is filled with water absorbing media like corncob. The wet components when tumbled with corncob, it gets nice wiping action and Stain Free Drying is achieved. Longer process time here enhances luster of the components. The time cycle can be infinitely varied after which the unload flap is flipped into position and parts are discharged via the unloading screen. The cob remains in the bowl. Vibromatic Industries range of driers ensures parts dry stain and corrosion free following the mass finishing process. This is particularly important if parts are to be painted or plated as a final operation. Driers are an essential part of the complete mass finishing solution.. FEATURE Continuous / recirculatory operation. Can be automated and added onto the total system. Variable speed controller. Sound and dust control lids. Rugged heavy duty special vibratory motor. In built separation arrangement.

Vibratory Fluid Bed Dryer

Get Price Quote

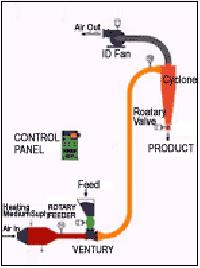

ACMEFIL Fluid Bed processing includes Drying as well as granulation, agglomeration and coating of particulate materials. It is designed to uniform drying of the material at low temperature and is ideal for a wide range of both heat sensitive and non-heat sensitive prodcts for low moist powder. In case of fluid bed coater cum granulator, agglomeration and granulation may be performed in a number of ways depending upon the feed to be processed and the product properties to be achieved. Fluid bed coating of powders, granules involves the spraying of a liquid on the fluidised powder under strictly controlled conditions. We offer fluid bed drying system made up of S.S.304 / S.S. 316 with GMP standards. The complete unit is supplied with suitable motor, blower, filters, filter bag, & control panel. Heating system will be provided as per customer requirement i.e. Steam / Electric Heating system and any other. Salient Features Availabale capacity of Fluid Bed Dryer is 2.5 Kgs to 300 Kgs. Time, space, energy and labour saver Automatic shaking arrangement Safe earthing device with low voltage relay Design confirming to cGMP norms and its documentation Flame proof electrical PLC for automation and control Single piece construction with modular type design HEPA Filtration system Dehumidification of inlet air Solid Particle Flow Monitor Sampling port on product container Vibratory Fluid Bed Dryer - Continuous type These driers have a bed of solid particles, which are fluidized by passing a stream of air or gas upward through a specially designed perforated sheet. The upward velocity of air is so maintained so as to slightly lift the solid particles and set them in motion. This motion can be utilized to bring about mixing as well as forward movement of the solids. The air or the gas is heated and the heat is utilized to dry the solids. Fines get agglomerated to larger particles thus providing large size granules. A vibratory motor can also be used to provide a mechanical forward motion to the fluidized solid particles. APPLICATIONS OF FLUID BED DRYER VIBRATORY TYPE Fluid Bed dryers have universal applications like: Chemical Industry Pharmaceuticals Industry Bio-Chemicals Industry Polymer Industry Food and Dairy Products Industry

Vibratory Dryer Machine

100,000 Per Units

Vibrating Fluid Bed Dryer

Get Price Quote

Vibratory Bowl Dryer

Get Price Quote

Vibratory Bowl Dryer, polyurethane lining, Glass Bead, burnishing machine

Vibro Dryer

Get Price Quote

Vibro Dryer, Non Woven Abrasives, grip handle