U Tube Heat Exchanger

20,000 - 60,000 Per Piece

1 Piece (MOQ)

U Tube Heat Exchanger

Get Price Quote

1 Piece (MOQ)

Best Deals from Tube Heat Exchangers

Tube Type Heat Exchanger

Get Price Quote

U Tube Heat Exchanger

Get Price Quote

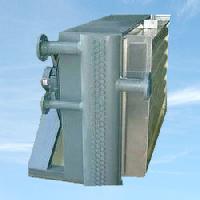

Finned Tube Heat Exchanger

Get Price Quote

We offer Finned Tube Heat Exchangers, which are designed as per the international standards and requirements of the clients. These Finned Tube Heat Exchangers can be employed for cooling or heating of air or other gases which flow in a duct or cooling of water and other liquids using air. Also, these Finned Tube Heat Exchangers are provided with Aluminium extruded finned tubes. These Finned Tube Heat Exchangers are manufactured with copper, aluminum, stainless steel, admiralty brass, cupro-nickel or carbon steel. Apart from this, these strongly constructed Finned Tube Heat Exchangers are widely used in different applications like air laden with abrasive particles, corrosive fluids and air heating with steam and designed for special custom-built applications. Highlights Rugged construction Corrosion resistant Available with customization High durability Low maintenance cost Trouble-free operation Industrial Applications Food processing Textile SugarDrier Manufacturing Cement plants

Tube Heat Exchanger

Get Price Quote

MS Tube Heat Exchanger

Get Price Quote

Shell & Tube Heat Exchanger

Get Price Quote

Shell and Tube Heat Exchangers

Get Price Quote

we at jc equipments pvt ltd in coimbatore offer world class heat exchanger particularly shell type. we offer all types of shell and tube heat exchanger for all industrial applications. where ever the pressure and temperature is available its required our heat exchanger. in heat exchanger industry the most important type of usage in oil industries and chemical process. this shell and tube heat exchanger having two parts. one is shell side and another one is tube side. jc equipments pvt ltd offer the below types of shell and tube heat exchangers: jc fixed tube sheet heat exchanger jc removable tube bundle heat exchanger jc vertical shell and tube heat exchanger jc stainless steel shell and tube heat exchanger jc u tube bundle type heat exchanger

tube bundle heat exchangers

Get Price Quote

In nuclear power plants called pressurized water reactors, large heat exchangers called steam generators are two-phase, shell-and-tube heat exchangers which typically have U-tubes. They are used to boil water recycled from a surface condenser into steam to drive a turbine to produce power. Most shell-and-tube heat exchangers are either 1, 2, or 4 pass designs on the tube side. This refers to the number of times the fluid in the tubes passes through the fluid in the shell. In a single pass heat exchanger, the fluid goes in one end of each tube and out the other. In Offshore Industries, Water Makers are made up of U tube Heat Exchangers. To Maintain the Lower Pressure Drop in High Tube Length. A tube bundle heat exchanger with baffles is disclosed wherein a tube bundle is housed within an inner casing which is acted upon from both the inside and the outside by a heating medium A multiple tube bundle heat exchanger includes axially opposite tube plates, a housing, and a plurality of tube bundles disposed between the tube plates. Each of the tube bundles is an independent tube bundle subassembly forming an integral unit having at least one heat exchanger tube with two axial tube ends.

Shell Tube Heat Exchanger

Get Price Quote

BCS manufacturers Shell and Tube Heat Exchanger that are designed to meet the standards of ASME SEC VIII Div-1 and TEMA standards.We have our own facilities for POST WELD HEAT TREATMENT, RADIOGRAPHIC.Our Heat Exchangers are constructed to meet the standards of ASME Sec-II Part A & B, We have qualified welders for all the welding needs.

Tube Bundle Heat Exchanger

Get Price Quote

We are the leading manufacturers of Tube bundle heat exchanger in India and available in a variety of designs and materials of construction. We having 23 years in this industry and JC Equipments makes three different models of tube bundle heat exchangers Which are designed for either horizontal or vertical use and Water Makers are made up of U tube Heat Exchangers. We manufacture the Cross flow tube bundle heat exchangers are often used in highly fouling environments such as lignite utility boilers. Tube Bundle Heat Exchanger Applications For preheating natural gas Non corrosive gas Heating requirements Industrial washing machines Oil coolers Gas coolers Condensers Chemical Marine Engines, Word boilers Tube Bundle Heat Exchanger Design JC Heat exchanger designed for installation with vertical tube bundle. Our new design increases the higher heat transfer rates. JC Heat exchanger designed for installation with vertical tube bundle. Our new design increases the higher heat transfer rates.

U Tube Bundle Heat Exchanger

Get Price Quote

We at JC Equipments Pvt Ltd the leading manufacturers of U Tube bundle heat exchanger in India with ASME certified and TEMA Standards . We build inner side U tube bundles [Hairpin Type tubes ] and outer side covered with shell. For Inner side U tube we use copper tubes and steel tubes. As per TEMA standard we can engineering and reverse engineering of U tube Heat exchanger and can duplicate your existing working U tube with custom build sizes and materials. Other Types of Tube Bundles are Fixed Tube Bundles, Removable Tube Bundles, Straight Tube, U Tube, Single Wall and Double Wall JC U Tube bundle Heat exchanger are useful for your higher-pressure and Higher Temperature applications requirements. We also supply U tube budle assemblies only. We assemble with proper care and needfull backup for transporting. Also testing repairing and cleaning of u tube bundle heat exchanger with expert team. You can use our U tubes for Hairpin type heat exchanger.

finned tube heat exchangers

Get Price Quote

Finned Tube Heat Exchangers is a type of heat exchanger design that uses plates and finned chambers to transfer heat between fluids. It is often categorized as a compact heat exchanger to emphasise its relatively high heat transfer surface area to volume ratio. The plate-fin heat exchanger is widely used in many industries, including the aerospace industry for its compact size and lightweight properties, as well as in cryogenics where its ability to facilitate heat transfer with small temperature differences is utilized. A high degree of flexibility is present in plate-fin heat exchanger design as they can operate with any combination of gas, liquid, and two-phase fluids. Heat transfer between multiple process streams is also accommodated, The main four type of fins are: plain, which refer to simple straight-finned triangular or rectangular designs; herringbone, where the fins are placed sideways to provide a zig-zag path; and serrated and perforated which refer to cuts and perforations in the fins to augment flow distribution and improve heat transfer. Specifications : Originally conceived by an Italian mechanic, Paolo Fruncillo. A plate-fin heat exchanger is made of layers of corrugated sheets separated by flat metal plates, typically aluminium, to create a series of finned chambers. Separate hot and cold fluid streams flow through alternating layers of the heat exchanger and are enclosed at the edges by side bars. Heat is transferred from one stream through the fin interface to the separator plate and through the next set of fins into the adjacent fluid. The fins also serve to increase the structural integrity of the heat exchanger and allow it to withstand high pressures while providing an extended surface area for heat transfer. Applications : The cost of Fin heat exchangers is generally higher than conventional heat exchangers due to a higher level of detail required during manufacture. However, these costs can often be outweighed by the cost saving produced by the added heat transfer. Fin heat exchangers are generally applied in industries where the fluids have little chances of fouling. The delicate design as well as the thin channels in the fin heat exchanger make cleaning difficult or impossible. Advantages : High heat transfer efficiency especially in gas treatment Larger heat transfer area Approximately 5 times lighter in weight than that of shell and tube heat exchanger. Able to withstand high pressure

Tube Heat Exchanger

Get Price Quote

We are manufacturing and exporting a wide range of heat exchangers suitable for heat transfer fluids, lubricating oil, power pack oil and other process coolants. Three types of shell and tube heat exchangers namely fixed tube sheet type, removable bundle type and u-tube type. Fixed type heat exchangers are used where there are absolutely no chances for inter mixing of two fluids. In this type, the tube sheets are completely welded to the shell and acted as shell flanges. The floating type heat exchangers has the advantages of removability of tube bundle and access for cleaning both inner and outer side of tubes and shell. We provide well conceived optimum designs to suit every application of heat exchange and recovery of for captive consumption and o.e. Applications. The materials of construction used are copper, stainless steel, mild steel, brass and cupro - nickel. Heat exchangers for sea water marine application or with steels shells are also offered & designed as per customer specific requirements. Advantages 1. attachment of tubes to single tubesheet eliminates the need for differential expansion joint. 2. this type is suitable for high pressure. 3. high degree of protection from leakage is possible. 4. double tubesheet is possible to provide further protection from leakage.

U-Tube Heat Exchanger

Get Price Quote

U-Tube Heat Exchanger can be many variations on the shell and tube design. Typically, the ends of each tube are connected to plenums through holes in tubesheets.

Tube Heat Exchanger

15,200 Per Piece

Finned Tubes Heat Exchanger

Get Price Quote

We are offering finned tubes heat exchanger.heat exchangers are generally a kind of device exchange heat in between two stages or levels and this is a type of same device being constructed of airfoil tubing. Finned tube heat exchanger is nothing but an exchanger consist of a long shell wrapped with a temperature resistant airfoil. They are useable in food, chemical and textile industries deals with liquid products. Specifications: type : refrigerator parts model : heat exchanger size : different size available

Shell and Tube Heat Exchanger

Get Price Quote

Janani Enterprises is engaged as Shell And Tube Heat Exchanger Manufacturer, Exporter and Supplier in Tamil Nadu, India. The latest technology, high performance Shell And Tube Heat Exchanger that we provide is result-oriented for process industries and for oil cooling. The tubes used internally are deliberately of various shapes and design to obtain different outcomes. While a few of the tubes may be plain, others may come finned longitudinally or horizontally. Additionally, the tubes can also be of various materials and thermal conductivity. For instance, Janani Enterprises Equipment can be designed from carbon steel, stainless steel, cupronickel, copper or brass. Materials Used And Suitability Shell And Tube Heat Exchanger is made of Copper, S.S,M.S. Tubes with M.S, S.S Shell for different applications as per Customer requirement suitable for Generators, Air Compressors, Inter, after, Coolers Chillers and Chemical Processes. Testing Of Heat Exchanger Owing to the complex nature of the shell and tube heat exchangers, regular inspection of the equipment is necessary. This can help to assess the thickness of the tube walls that are prone to fitting, erosion and corrosion over time. The status of the whole bundle of tubes may be charted and assessed through a thorough inspection with the help of a device known as internal rotary inspection system that functions via ultra sonic testing and also has a non-destructive nature Specifications Design ShellLength up to 20,000 mmWeight up to 20 metric tonnesPressure up to 300 Kg/cm3Temperature up to 1000oCTube Plate Diameter up to 4000 mmThickness up to 400 mm Features Materials we used for Shell, carbon steel, stainless steel sizes up to 20000 mmTubes Copper, Brass, Cupro-nickel, Carbon Steels in sizes from 6 mm to 50 mm OD, Stainless SteelsTube Sheets : Carbon Steel, Stainless Steel, Brass etc.Channels and Cover : Carbon Steel, Stainless Steel, Case Iron, Brass, Mild Steel etc.Gaskets : Rubber, Compressed Applications Chemical, PetrochemicalFertilizerThermal Power plantsRefrigeration PlantsMarine EnginesTurbines, Hydraulic SystemsSugar Machinery.

Shell and Tube Heat Exchanger

Get Price Quote

Target Equipments design of the shell and tube heat exchanger is quite complex. The tubes used internally are deliberately of various shapes and design to obtain different outcomes. While a few of the tubes may be plain, others may come finned longitudinally or horizontally. Additionally, the tubes can also be of various materials and thermal conductivity. For instance, Target equipments can be designed from carbon steel, stainless steel, cupronickel, copper or brass. Testing Of Heat Exchanger Owing to the complex nature of the shell and tube heat exchangers, regular inspection of the equipment is necessary. This can help to assess the thickness of the tube walls that are prone to pitting, erosion and corrosion over time. The status of the whole bundle of tubes may be charted and assessed through a thorough inspection with the help of a device known as Internal Rotary Inspection System that functions via ultra tonic testing and also has a non-destructive nature Specification Features Materials we used for Shell :, Copper, Carbon steel, stainless Steel sizes up to 20000 mm, Tubes Copper, Brass, Cupro-nickel , Carbon Steels in sizes from 6 mm to 50 mm OD, Stainless Steels, Tube Sheets: Carbon Steel, Stainless Steel, Brass etc. Channels and Cover : Carbon Steel, Stainless Steel, Case Iron, Brass etc. Gaskets : Rubber, Compressed Application Chemical, Petrochemical, Fertiliser. Thermal Power plants, Refrigeration Plants, marine Engines, Turbines, Hydraulic Systems, Sugar Machinery .

Steel Tube Heat Exchanger

Get Price Quote

Shell and Tube Heat Exchanger

Get Price Quote

Gireesh shell and tube heat exchanger is the most common type of heat exchanger designs. As its name implies, this type of heat exchanger consists of a shell with a bundle of tubes inside it. One fluid runs through the tubes, and another fluid flows over the tubes (through the shell) to transfer heat between the two fluids. The set of tubes is called a tube bundle, and may be composed by several types of tubes: plain, longitudinally finned, etc. process liquid or gas cooling process or refrigerant vapour or steam condensing process liquid, steam or refrigerant evaporation process heat removal and preheating of feed water thermal energy conservation efforts, heat recovery compressor, turbine and engine cooling, oil and jacket water hydraulic and lube oil cooling

Shell and Tube Heat Exchanger

Get Price Quote

Our Shell and Tube Heat Exchangers are furnished with 19 mm copper tubes, carbon steel components, and a durable cast iron head. Our range of Shell and Tube Heat Exchangers provide protection in any event of a leak.

tube bundle heat exchangers

Get Price Quote

We are the leading manufacturers of Tube bundle heat exchanger in India and available in a variety of designs and materials of construction. makes three different models of tube bundle heat exchangers Which are designed for either horizontal or vertical use and Water Makers are made up of U tube Heat Exchangers. We manufacture the Cross flow tube bundle heat exchangers are often used in highly fouling environments such as lignite utility boilers.

Tube Heat Exchangers

Get Price Quote

One fluid runs through the tubes, and another fluid flows over the tubes to transfer heat between the two fluids is known as Shell and Tube heat exchangers.

Finned Tube Heat Exchanger

Get Price Quote

Finned Tube Heat Exchangers consist of a shell & finned tubes assembly. Fins are used to increase the effective surface area of heat exchanger tubing. Finned tubes are used when the heat transfer coefficient on the outside of the tubes is appreciably lower than that on the inside; as in heat transfer from a liquid to a gas, vapor to a gas, such as steam to air heat exchanger, thermic fluid to air heat exchanger. When an extended surface is needed on only one fluid side (such as in a gas to liquid exchanger) or when the operating pressure needs to be contained on one fluid side, a finned tube heat exchanger may be selected. Applications of finned tube heat exchangers include Steam air heater / steam radiator, Thermic fluid air heater / thermic fluid radiator, Hot water air heater / hot water radiator, Air heater for fluid bed dryers, Air heater for spray dryers, Air heater for flash dryers and Air heater for dryers.

Removable Tube Sheet Heat Exchangers

Get Price Quote

Removable Tube Sheet Heat Exchangers to Elliott for all your tube removal needs ranging from tube cutters to tube tuggers to pneumatic hammers.The tube removal process includes several process steps that must be performed with critical sequencing & tolerances. The initial step of our process the Tungsten Inert Gas (TIG) shrinking of the tube to-tube sheet expansion joints (where applicable), which performed with our st&ard plug removal TIG system. Hard rolled & tubes the shrinking process necessary to relieve the radial stress between the tube & tube sheet.

Shell Tube Heat Exchanger

Get Price Quote

Shell and Tube heat exchangers are suitable for heat transfer fluids,lubricating oil,power pack oil and other process coolants.Models available in wide range(4" to 10") shell diameter suitable for load 1500 KcalHr to 75000 Kcalhr.(2 Hp to 100Hp).

Shell and Tube Heat Exchanger

15,000 Per unit

1 unit (MOQ)

Shell Tube Heat Exchanger

Get Price Quote

We JC Equipments Pvt Ltd take Pleasure to Introduce Ourselves as one of the leading Designers, Manufacturers & Exporting of all kind of Cooling Towers,Heat Exchangers Pressure Vessels Columns, Storage Tanks, Air Cooled Condensers, etc... in India. JC Equipments Pvt Ltd started in the Year of 1989. We have wide knowledge in this field and we have Regular customers throughout the world. We are AUTHORIZED MANUFACTURERS OF ASME and we have “U, S & R” Stamp Certification also. We are CORPORATE MEMBER OF CTI, USA. We are a WORLD CLASS MANUFACTURERS and we never compromise in Quality. We assure Our Product will be best quality and competitive price. Herewith we have enclosed the product profile for your kind reference. Kindly refer the attachment. Looking forward your valuable enquiry for us to quote our best and competitive offers, with assuring you of our best quality and prompt service at all times.