+2

+2

Universal Material Testing Machine

Get Price Quote

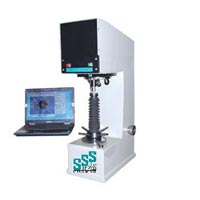

Computerized Vickers Hardness Testing Machine

250,000 - 800,000 / Piece

+2

+2

Computerized Tensile Testing Machine

398,000 / piece

MECHANICAL UNIVERSAL TESTING MACHINE AI-UTN

Get Price Quote

Universal Testing Machines

Get Price Quote

Mechanical Universal Testing Machine

Get Price Quote

Universal Testing Machine - Mechanical - Mech.CS.UTM

Get Price Quote

Mechanical Tensile Testing Machine

Get Price Quote

Electronic Universal Testing Machine

546,000 / Piece

Computerized Hardness Testing Machine

Get Price Quote

Digital Universal Testing Machine

Get Price Quote

6 Pillar Universal Testing Machine

Get Price Quote

Mechanical Universal Testing Machine

Get Price Quote

UTM-300 Mechanical Universal Testing Machine

300,000 - 700,000 / piece

Universal Testing Machine

Get Price Quote

Computerized Universal Testing Machine

Get Price Quote

Universal Testing Machines

Get Price Quote

Electro Mechanical Universal Testing Machines

Get Price Quote

Universal Testing Machines

900,000 / Piece

Tensile Tetsing Machine

Get Price Quote

Universal Testing Machines

Get Price Quote

Mechanical Universal Testing Machines

Get Price Quote

Tensile Testing Machines

Get Price Quote

Digital Universal Testing Machine

Get Price Quote

Tensile Strength Tester

Get Price Quote

Front Open Universal Testing Machine

Get Price Quote

Electronic Universal Testing Machine

Get Price Quote

Mechanical Universal Testing Machine

Get Price Quote

Computerised Brinell Hardness Testing Machines

Get Price Quote